Release 2.9.0 (r2020-1)

Copyright © 2020 Pi Innovo

13-Apr-2020

Table of Contents

- Foreword

- 1. Introduction

- 2. Installation

- 2.1. Introduction

- 2.2. Installing OpenECU

- 2.3. License setup

- 2.4. Removing OpenECU

- 2.5. Integration notes for third party tools

- 2.5.1. Microsoft Windows 10

- 2.5.2. Microsoft Windows 7

- 2.5.3. Microsoft Windows XP

- 2.5.4. MATLAB

- 2.5.5. PiSnoop

- 2.5.6. ATI Vision

- 2.5.7. ETAS INCA calibration tool

- 2.5.8. Vector CANape

- 2.5.9. Wind River (Diab) C Compiler v5.5.1.0

- 2.5.10. Wind River (Diab) C Compiler v5.8.0.0

- 2.5.11. Wind River (Diab) C Compiler v5.9.0.0

- 2.5.12. GCC Compiler v4.7.3

- 2.5.13. Python

- 3. Quick start

- 4. Software overview

- 4.1. How to find OpenECU

- 4.2. Introduction to OpenECU

- 4.3. Simulink and OpenECU

- 4.4. System modes

- 4.5. Programming an ECU

- 4.6. OpenECU blockset features

- 4.6.1. Calibration tool support

- 4.6.2. Adaptive parameters

- 4.6.3. Communications

- 4.6.4. Compiler options

- 4.6.5. Deprecated blocks

- 4.6.6. Fault support

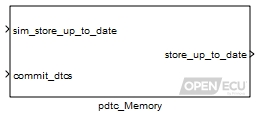

- 4.6.7. PID support

- 4.6.8. Freeze Frame support

- 4.6.9. Service $09 InfoType support

- 4.6.10. IUPR support

- 4.6.11. Analogue and digital inputs

- 4.6.12. Oxygen sensing — wide band UEGO

- 4.6.13. Operating system

- 4.6.14. Analogue and digital outputs

- 4.6.15. Real-Time Workshop (RTW) support

- 4.6.16. Target ECU identification and configuration

- 4.6.17. Timing

- 4.6.18. Utilities

- 4.6.19. Versioning

- 4.7. Adapting an existing model for OpenECU

- 4.8. Migrating between versions of Simulink

- 5. Design and modelling

- 6. Software detail

- 6.1. OpenECU blockset reference

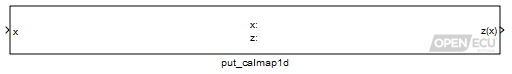

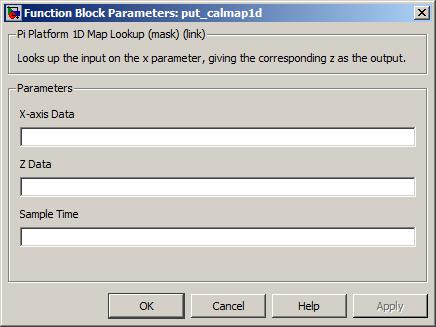

- 6.1.1. 1-d calibration map look-up and interpolation (put_Calmap1d)

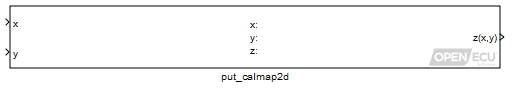

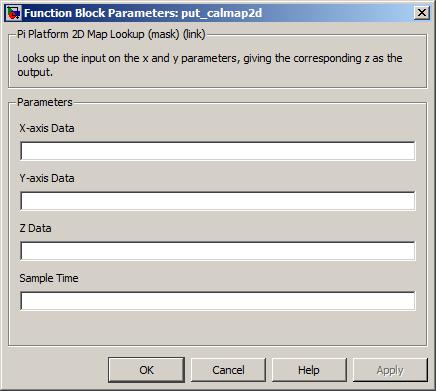

- 6.1.2. 2-d calibration map look-up and interpolation (put_Calmap2d)

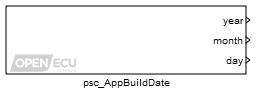

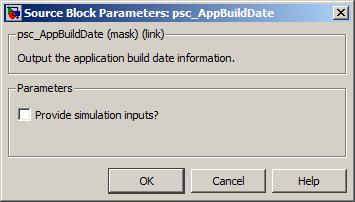

- 6.1.3. Application build date (psc_AppBuildDate)

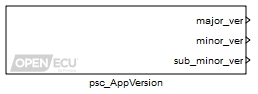

- 6.1.4. Application version (psc_AppVersion)

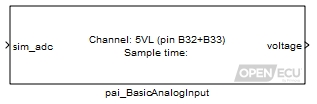

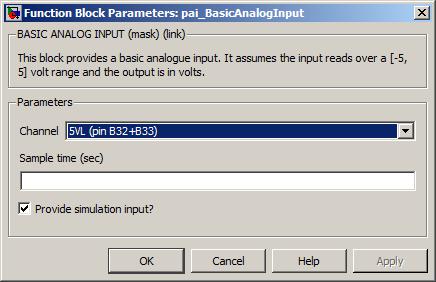

- 6.1.5. Analogue input — basic (pai_BasicAnalogInput)

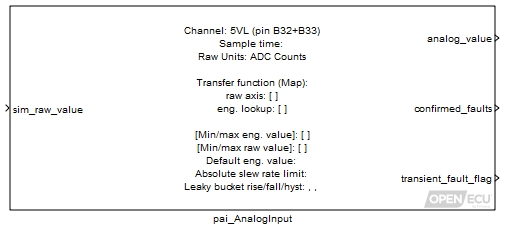

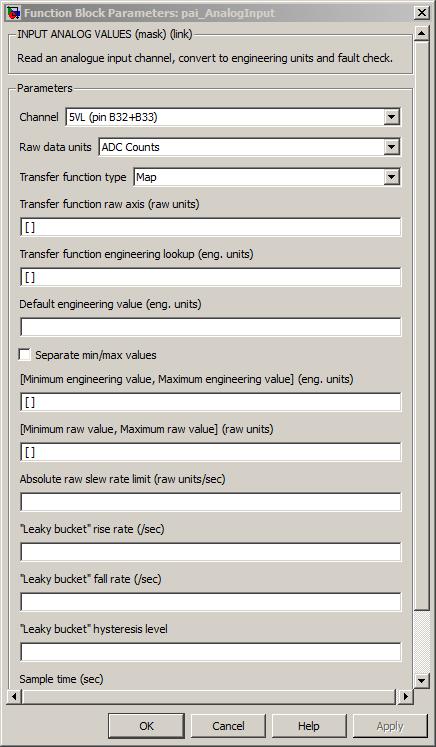

- 6.1.6. Analogue input — processed (pai_AnalogInput)

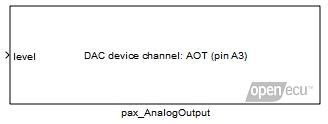

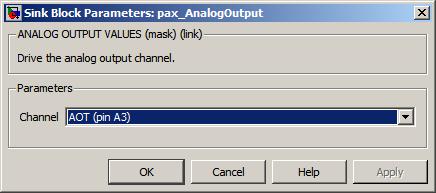

- 6.1.7. Analogue output (pax_AnalogOuput)

- 6.1.8. Build model (prtw_Build)

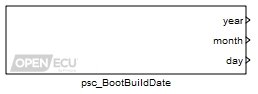

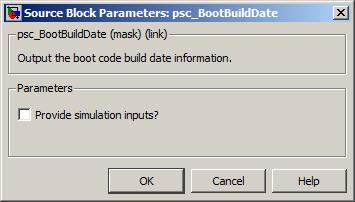

- 6.1.9. Boot code build date (psc_BootBuildDate)

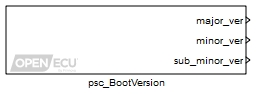

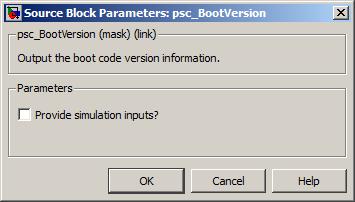

- 6.1.10. Boot code version (psc_BootVersion)

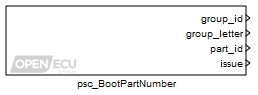

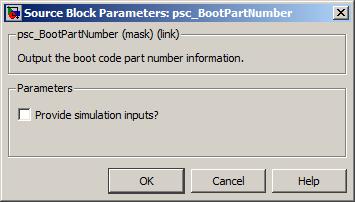

- 6.1.11. Boot code part number (psc_BootPartNumber)

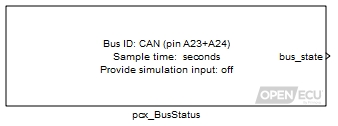

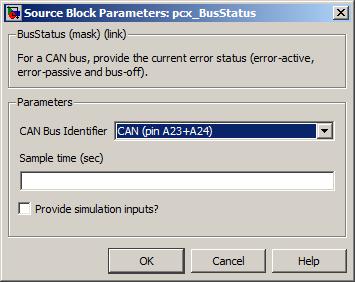

- 6.1.12. CAN bus status (pcx_BusStatus)

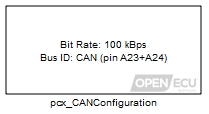

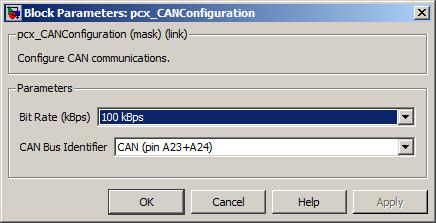

- 6.1.13. CAN configuration (pcx_CANConfiguration)

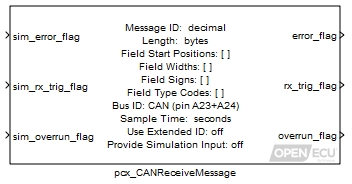

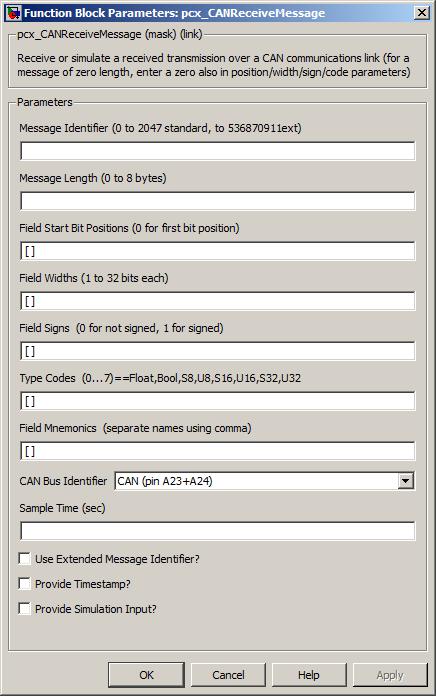

- 6.1.14. CAN receive message (pcx_CANReceiveMessage)

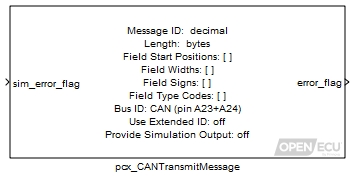

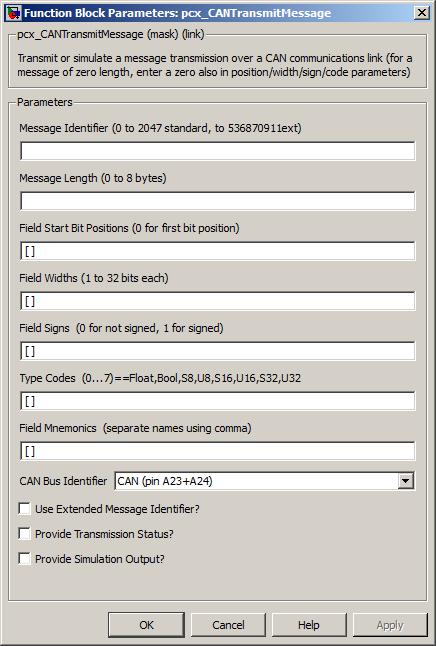

- 6.1.15. CAN transmit message (pcx_CANTransmitMessage)

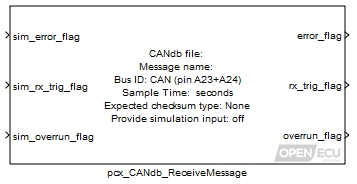

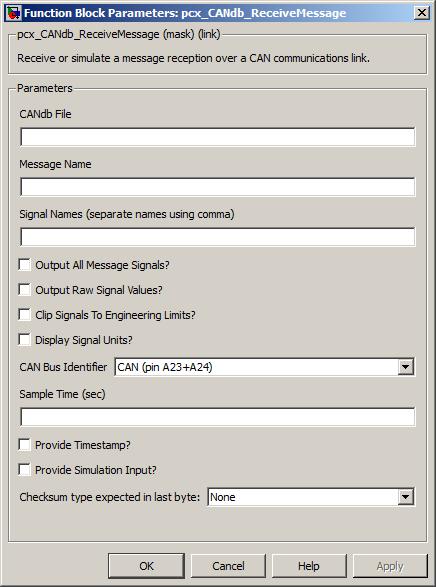

- 6.1.16. CANdb message receive (pcx_CANdb_ReceiveMessage)

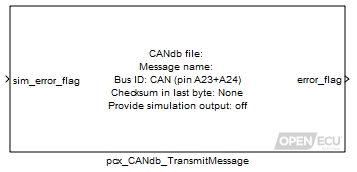

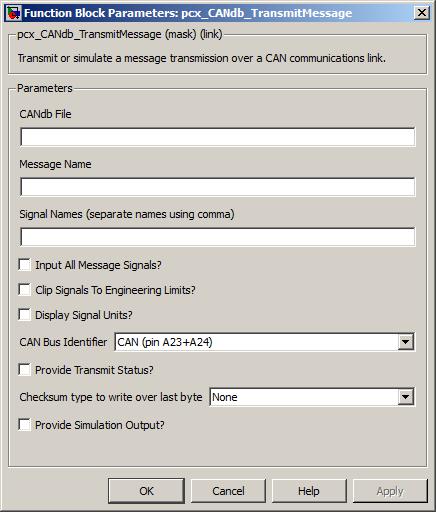

- 6.1.17. CANdb transmit message (pcx_CANdb_TransmitMessage)

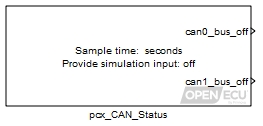

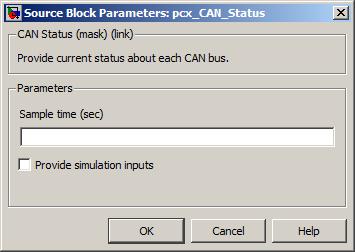

- 6.1.18. CAN status — deprecated (pcx_CANStatus)

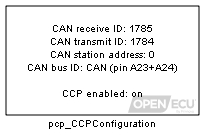

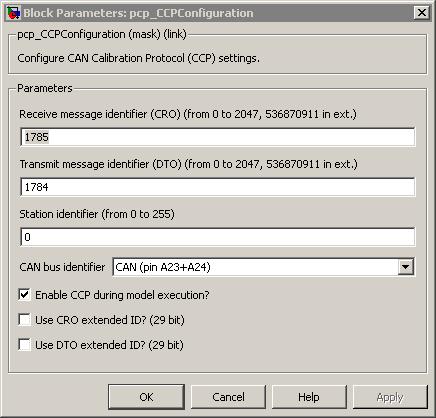

- 6.1.19. CCP configuration (pcp_CCPConfiguration)

- 6.1.20. CCP raster configuration (pcp_RasterConfig)

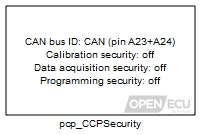

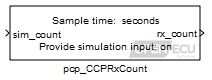

- 6.1.21. CCP seed/key security (pcp_CCPSecurity)

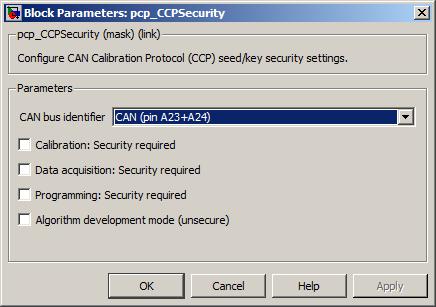

- 6.1.22. CCP inhibit reprogramming (pcp_CCPInhibitReprogramming)

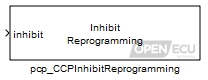

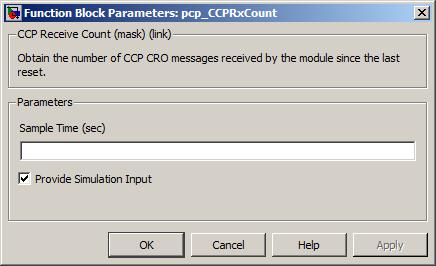

- 6.1.23. CCP CRO receive count (pcp_CCPRxCount)

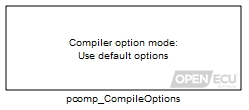

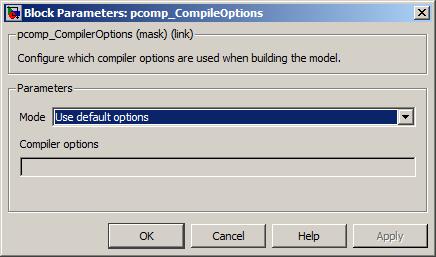

- 6.1.24. Compiler options (pcomp_CompileOptions)

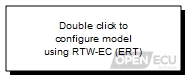

- 6.1.25. Configure auto-coder (RTW EC) (prtw_ConfigUsingRtwEc)

- 6.1.26. Configure auto-coder (RTW RTMODEL) (prtw_ConfigUsingRtwRtmodel)

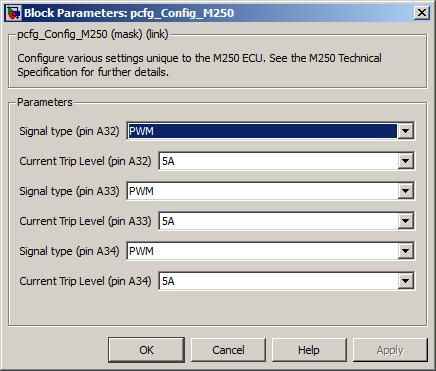

- 6.1.27. Configuration M250 (pcfg_Config_M250)

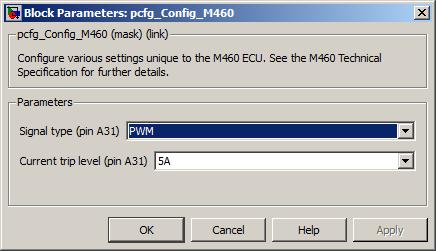

- 6.1.28. Configuration M460 (pcfg_Config_M460)

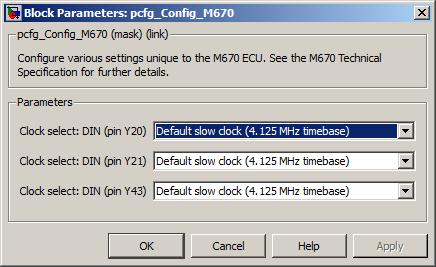

- 6.1.29. Configuration M670 (pcfg_Config_M670)

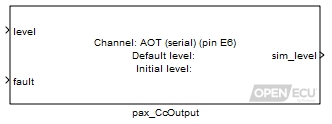

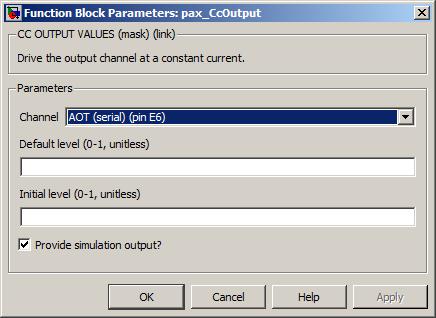

- 6.1.30. Constant current output (pax_CcOutput)

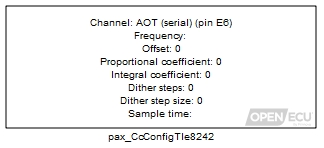

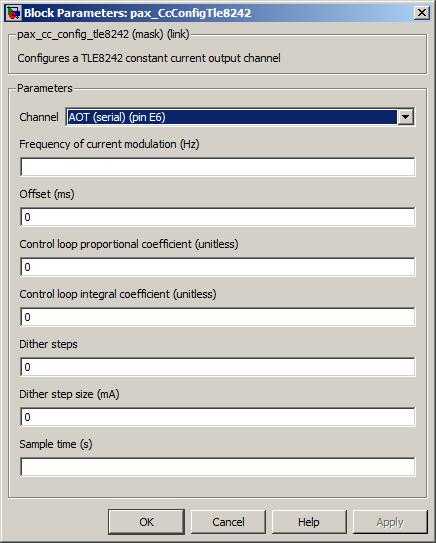

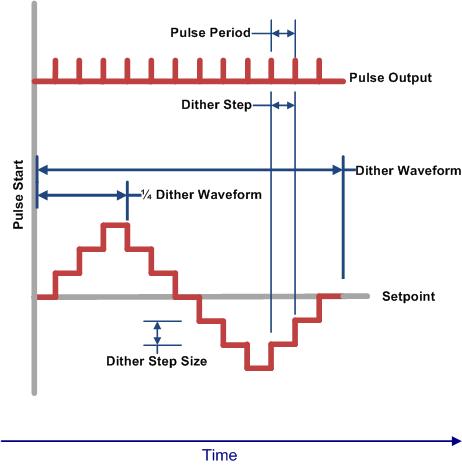

- 6.1.31. Constant current output — configuration for TLE8242-2 outputs (pax_CcConfigTle8242)

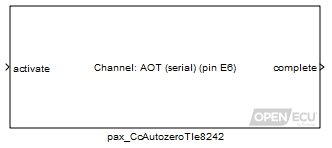

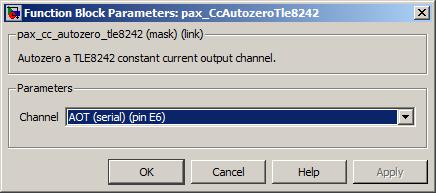

- 6.1.32. Constant current output — autozero for TLE8242-2 channels (pax_CcAutozeroTle8242)

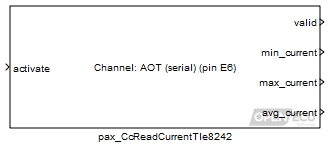

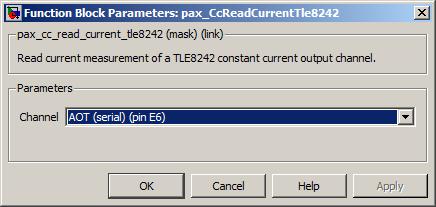

- 6.1.33. Constant current output — monitor for TLE8242-2 channels (pax_CcReadCurrentTle8242)

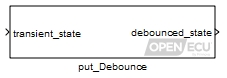

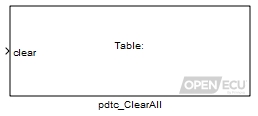

- 6.1.34. Debounce (put_Debounce)

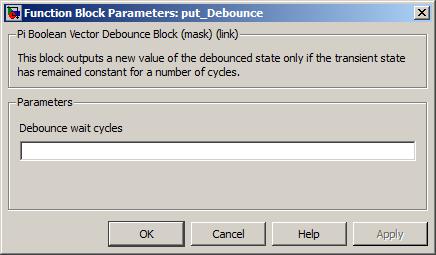

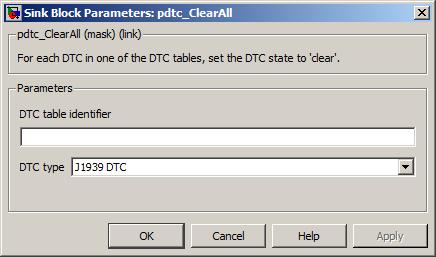

- 6.1.35. DTC clear all (pdtc_ClearAll)

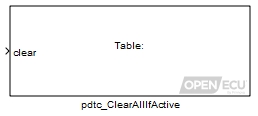

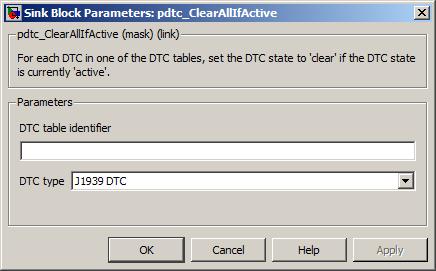

- 6.1.36. DTC clear all if active (pdtc_ClearAllIfActive)

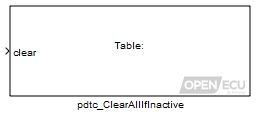

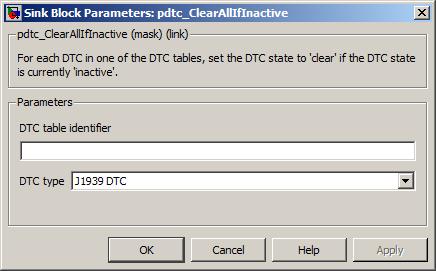

- 6.1.37. DTC clear all if inactive (pdtc_ClearAllIfInactive)

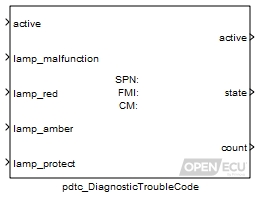

- 6.1.38. DTC diagnostic trouble code (pdtc_DiagnosticTroubleCode)

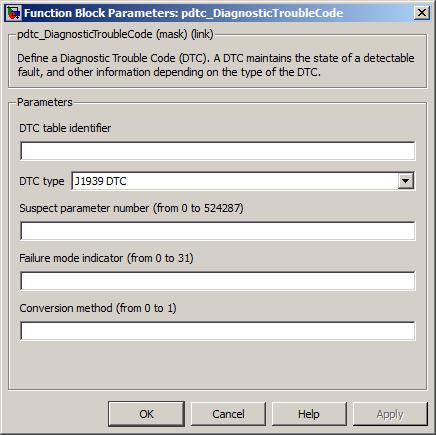

- 6.1.39. DTC enable periodic lamp updates (pdtc_EnablePeriodicLampUpdates)

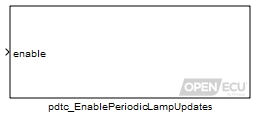

- 6.1.40. DTC memory update (pdtc_Memory)

- 6.1.41. DTC table definition (pdtc_Table)

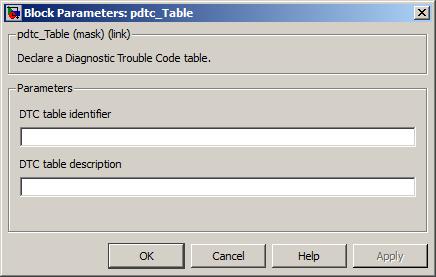

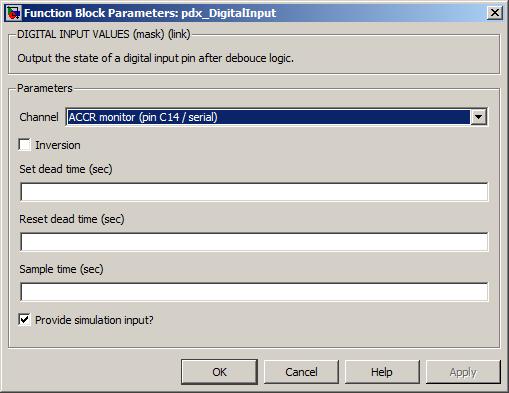

- 6.1.42. Digital input (pdx_DigitalInput)

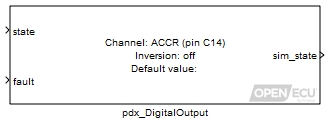

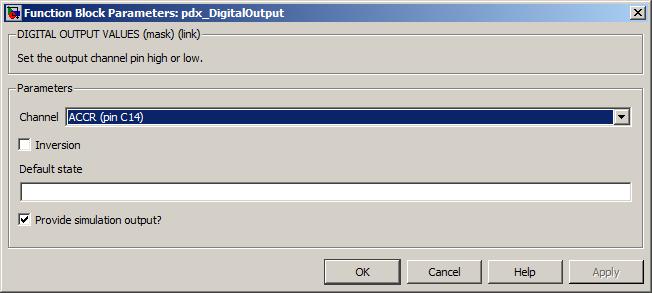

- 6.1.43. Digital output (pdx_DigitalOutput)

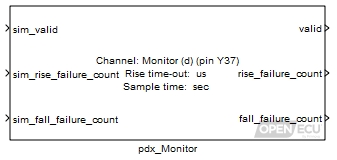

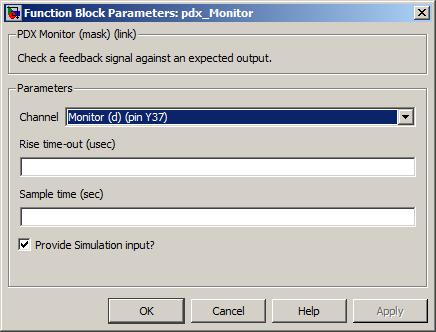

- 6.1.44. Digital output monitor (pdx_Monitor)

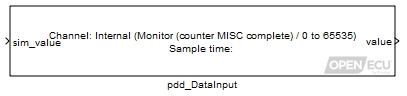

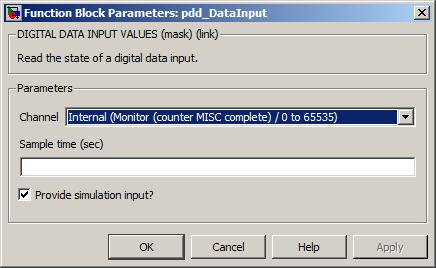

- 6.1.45. Digital data input (pdd_DataInput)

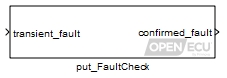

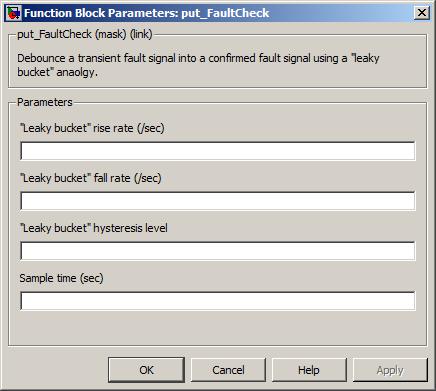

- 6.1.46. Fault check (put_FaultCheck)

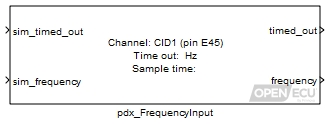

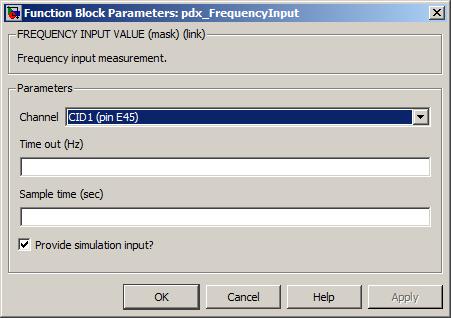

- 6.1.47. Frequency input (pdx_FrequencyInput)

- 6.1.48. Hall decode input measurement (pdx_HallDecodeInput)

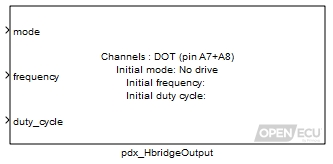

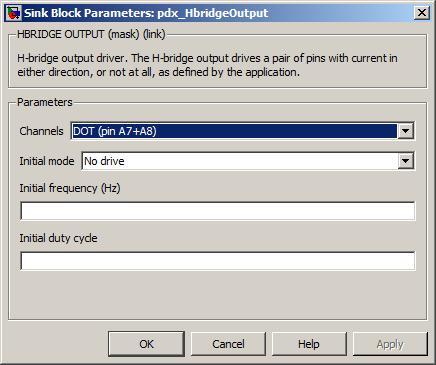

- 6.1.49. H-Bridge output (pdx_HBridgeOutput)

- 6.1.50. J1939 configuration (pj1939_Configuration)

- 6.1.51. J1939 channel configuration (pj1939_ChannelConfiguration)

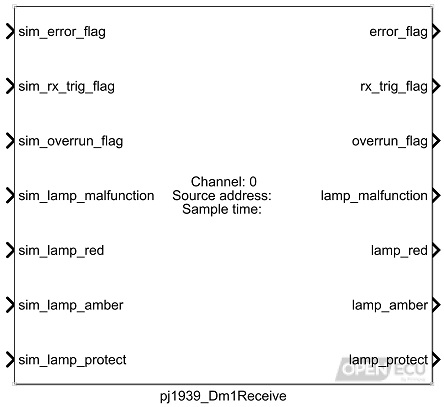

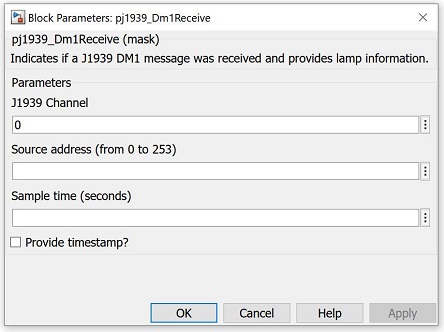

- 6.1.52. J1939 DM1 receive (pj1939_Dm1Receive)

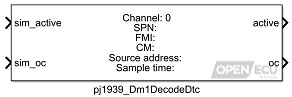

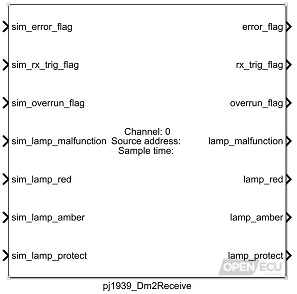

- 6.1.53. J1939 DM1 decode DTC (pj1939_Dm1DecodeDtc)

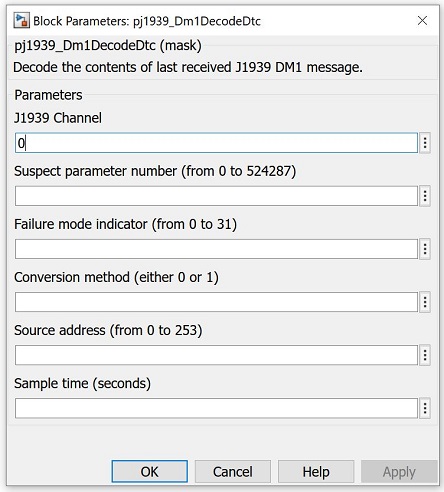

- 6.1.54. J1939 DM1 transmit (pj1939_Dm1Transmit)

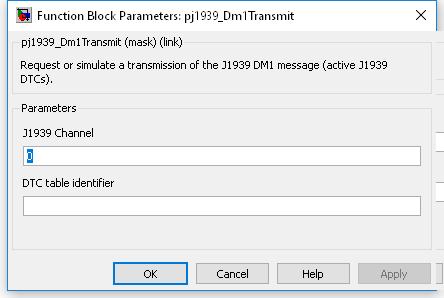

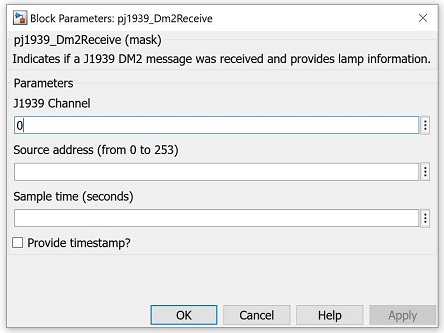

- 6.1.55. J1939 DM2 receive (pj1939_Dm2Receive)

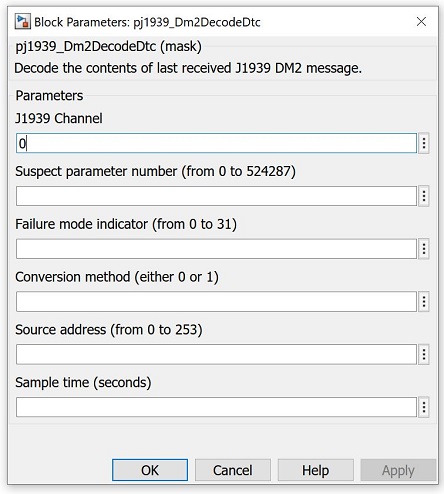

- 6.1.56. J1939 DM2 decode DTC (pj1939_Dm2DecodeDtc)

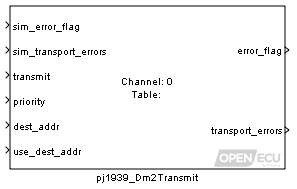

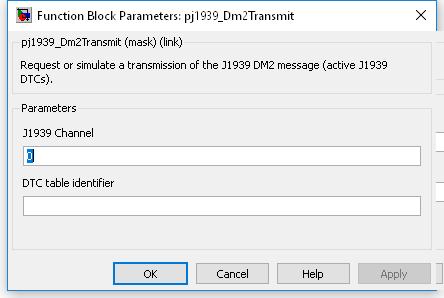

- 6.1.57. J1939 DM2 transmit (pj1939_Dm2Transmit)

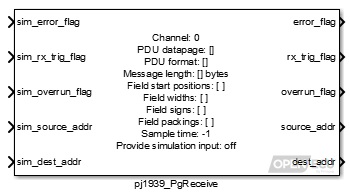

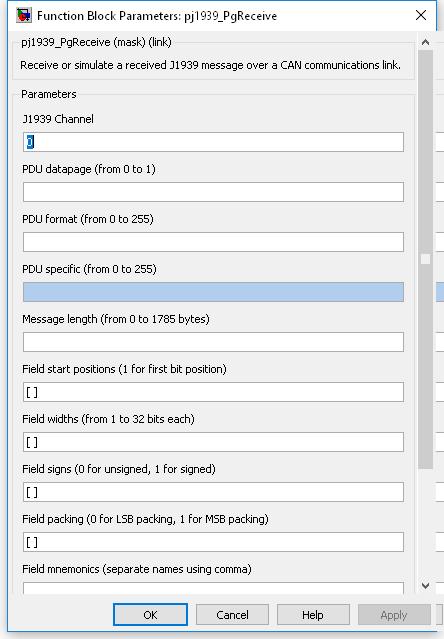

- 6.1.58. J1939 parameter group receive message (pj1939_PgReceive)

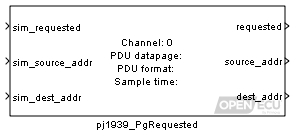

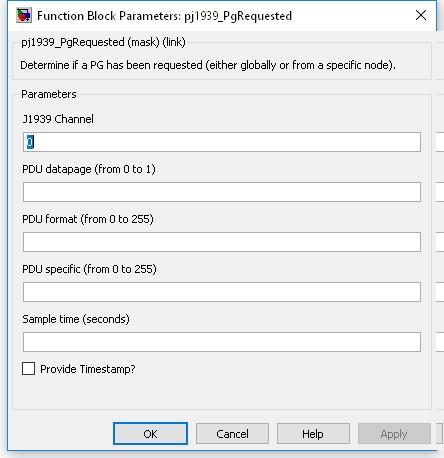

- 6.1.59. J1939 parameter group requested (pj1939_PgRequested)

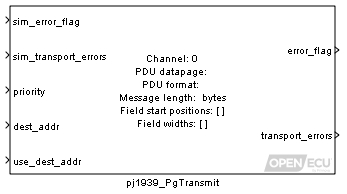

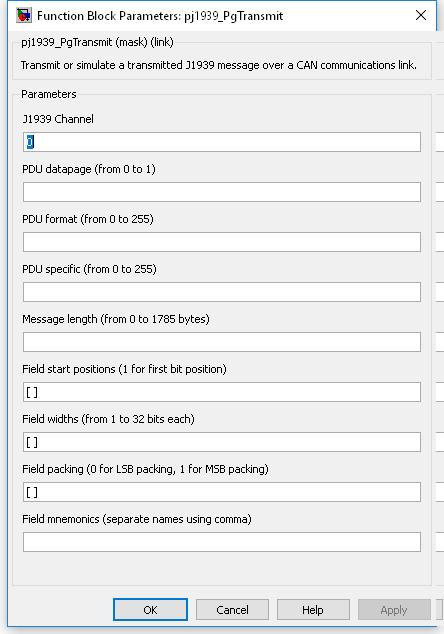

- 6.1.60. J1939 parameter group transmit (pj1939_PgTransmit)

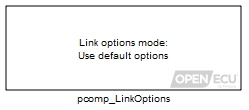

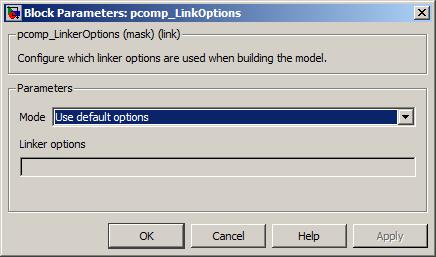

- 6.1.61. Link options (pcomp_LinkOptions)

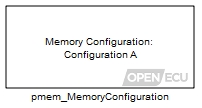

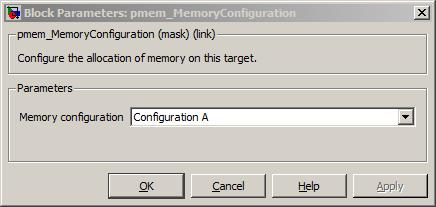

- 6.1.62. Memory configuration (pmem_MemoryConfiguration)

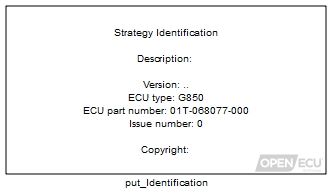

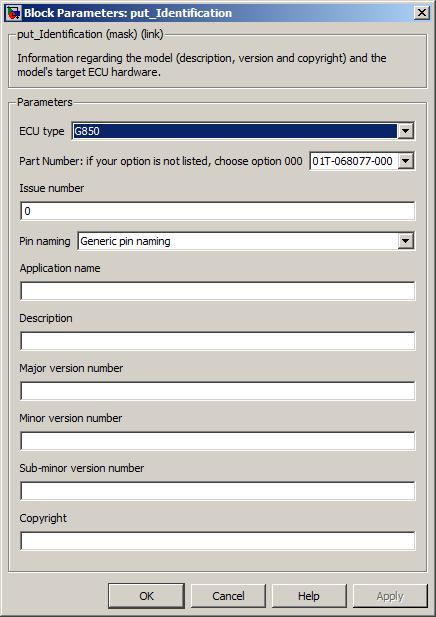

- 6.1.63. Model identification (put_Identification)

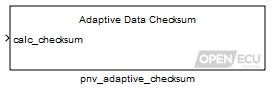

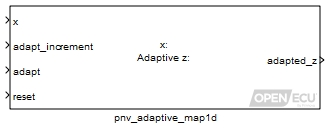

- 6.1.64. Non-volatile adaptive check-sum (pnv_AdaptiveChecksum)

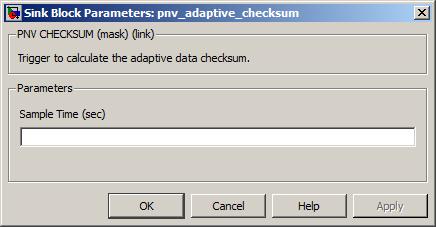

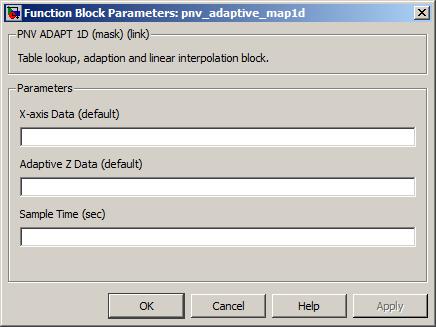

- 6.1.65. Non-volatile adaptive 1-d map look-up (pnv_AdaptiveMap1d)

- 6.1.66. Non-volatile adaptive 2-d map look-up (pnv_AdaptiveMap2d)

- 6.1.67. Non-volatile adaptive scalar (pnv_AdaptiveScalar)

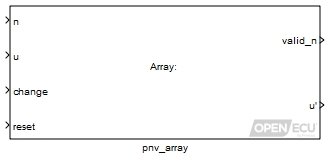

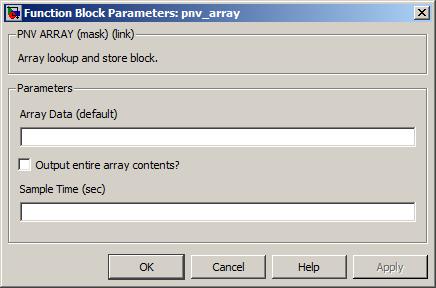

- 6.1.68. Non-volatile adaptive array (pnv_Array)

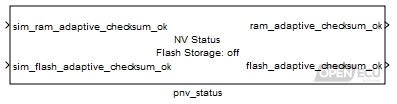

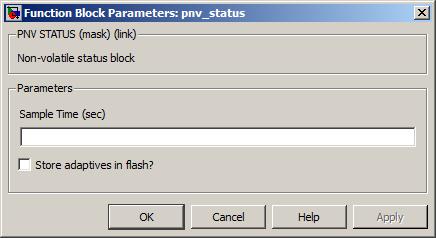

- 6.1.69. Non-volatile memory status (pnv_Status)

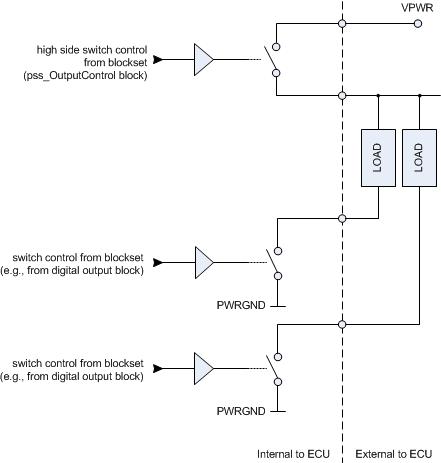

- 6.1.70. Output control (pss_OutputControl)

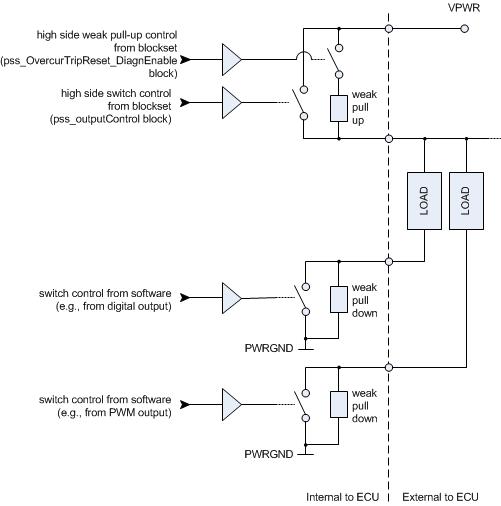

- 6.1.71. Over-current trip reset (pss_OvercurTripReset)

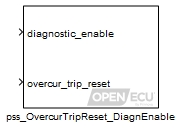

- 6.1.72. Over current trip reset and diagnostic enable (pss_OvercurTripReset_DiagnEnable)

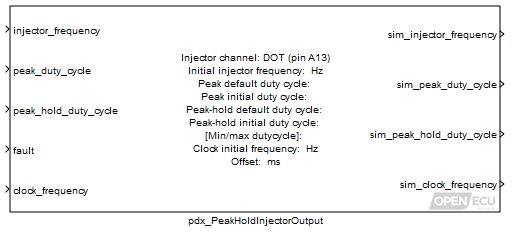

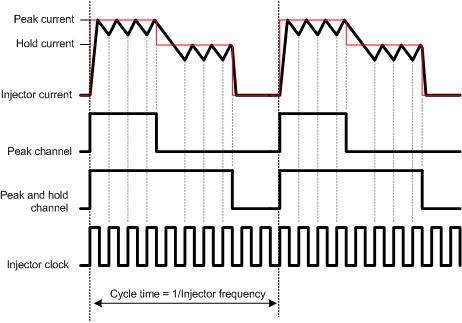

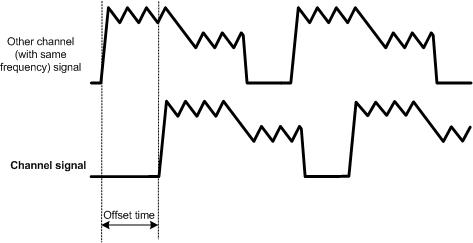

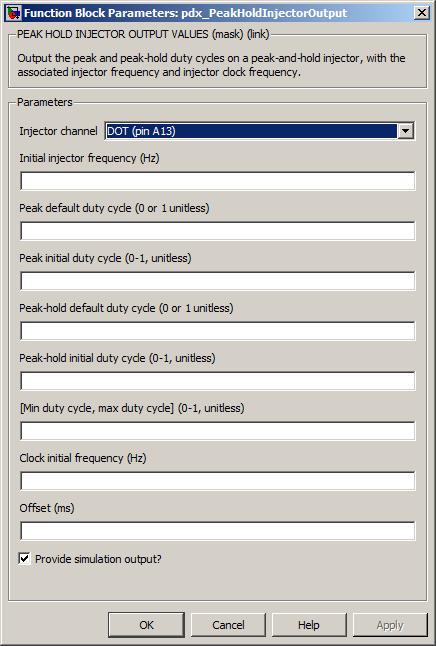

- 6.1.73. Peak and hold injector output (pdx_PeakHoldInjectorOutput)

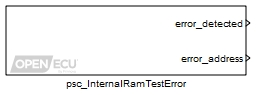

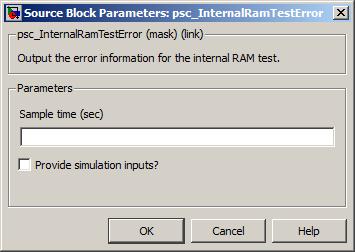

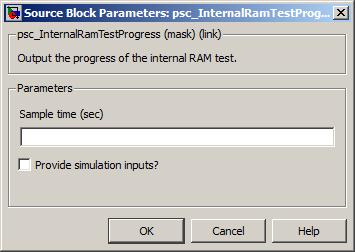

- 6.1.74. Internal RAM test error (psc_InternalRamTestError)

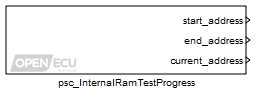

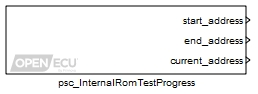

- 6.1.75. Internal RAM test progress (psc_InternalRamTestProgress)

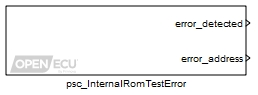

- 6.1.76. Internal ROM test error (psc_InternalRomTestError)

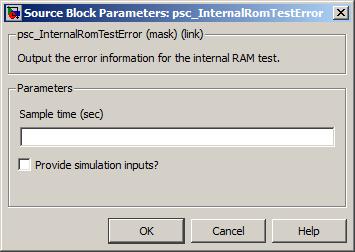

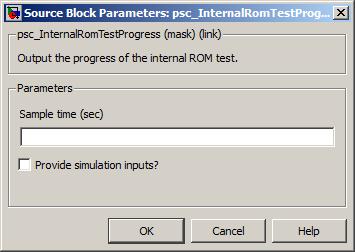

- 6.1.77. Internal ROM test progress (psc_InternalRomTestProgress)

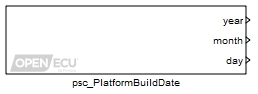

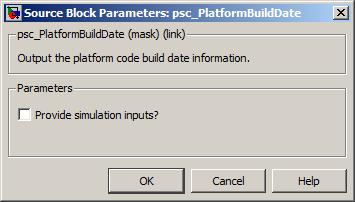

- 6.1.78. Platform code build date (psc_PlatformBuildDate)

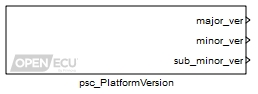

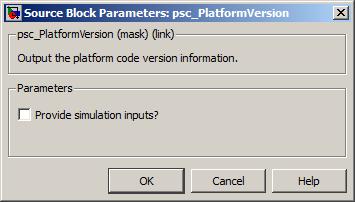

- 6.1.79. Platform code version (psc_PlatformVersion)

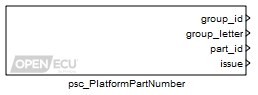

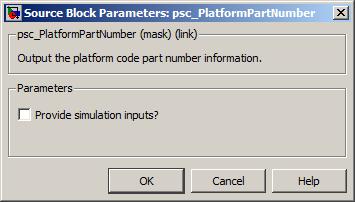

- 6.1.80. Platform code part number (psc_PlatformPartNumber)

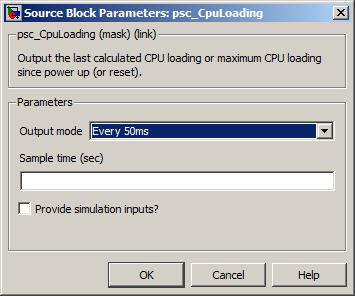

- 6.1.81. Processor loading (psc_CpuLoading)

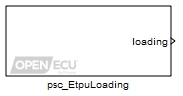

- 6.1.82. eTPU loading (psc_EtpuLoading)

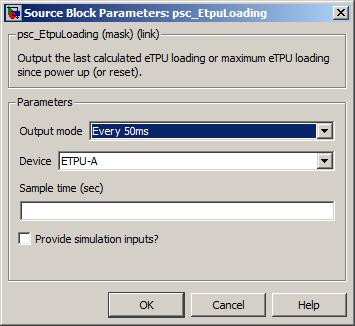

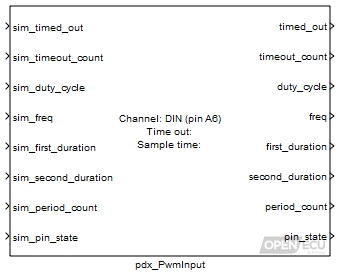

- 6.1.83. PWM input measurement (pdx_PwmInput)

- 6.1.84. PWM output — fixed frequency (pdx_PWMOutput)

- 6.1.85. PWM output — variable frequency (pdx_PWMVariableFrequencyOutput)

- 6.1.86. PWM output — with synchronous sampling (pdx_PWMOutputWithSyncSampling)

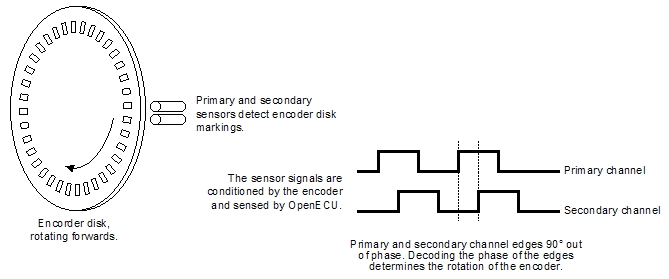

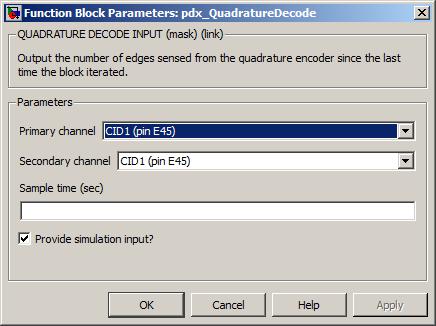

- 6.1.87. Quadrature decode input (pdx_QuadratureDecode)

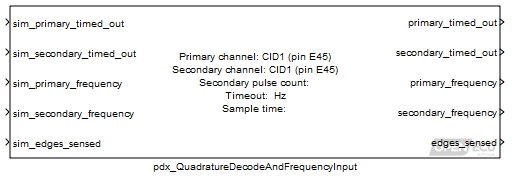

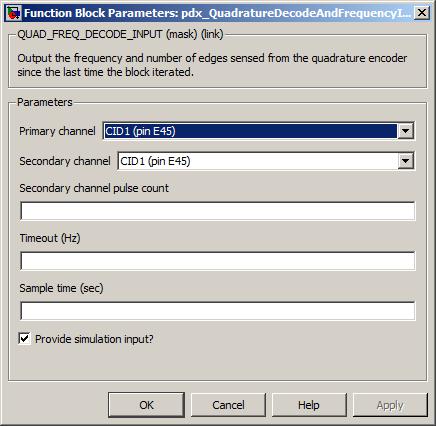

- 6.1.88. Quadrature decode and frequency input measurement (pdx_QuadratureDecodeAndFrequencyInput)

- 6.1.89. Range check (put_RangeCheck)

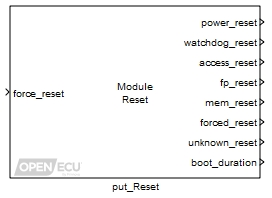

- 6.1.90. Reset module (put_Reset)

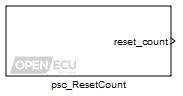

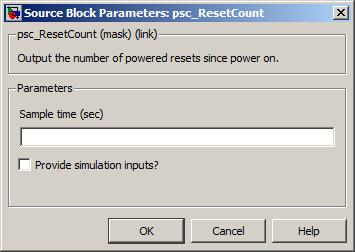

- 6.1.91. Reset count — stable (psc_ResetCount)

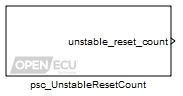

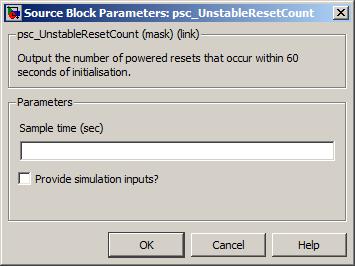

- 6.1.92. Reset count — unstable (psc_UnstableResetCount)

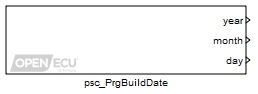

- 6.1.93. Reprogramming code build date (psc_PrgBuildDate)

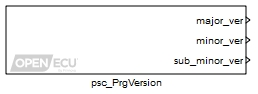

- 6.1.94. Reprogramming code version (psc_PrgVersion)

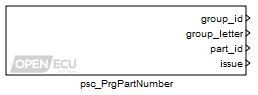

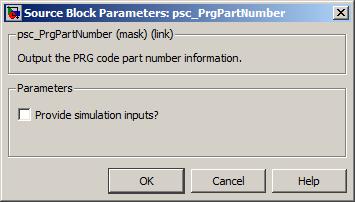

- 6.1.95. Reprogramming code part number (psc_PrgPartNumber)

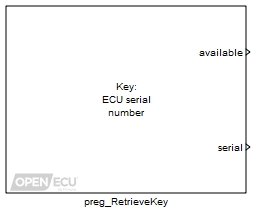

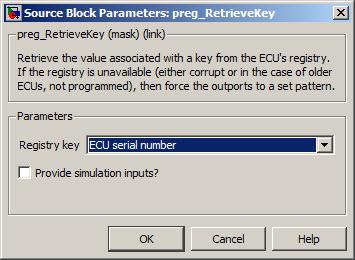

- 6.1.96. Retrieve registry key (preg_RetrieveKey)

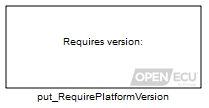

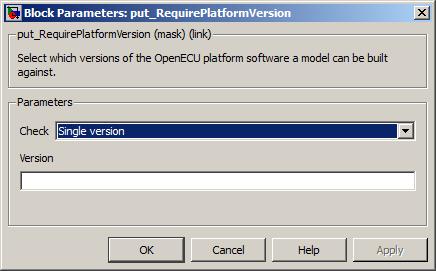

- 6.1.97. Require platform version (put_RequirePlatformVersion)

- 6.1.98. Show Simulink's sample time colours (prtw_ShowSampleTimeColours)

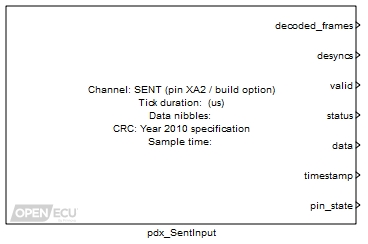

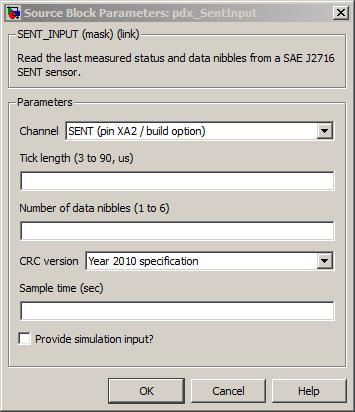

- 6.1.99. SENT input (pdx_SentInput)

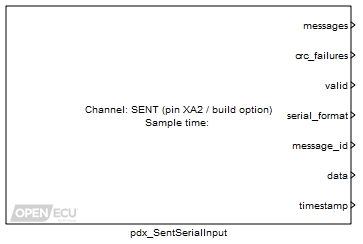

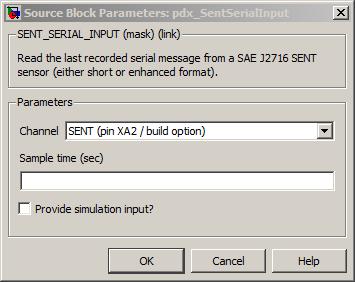

- 6.1.100. SENT input — serial data (pdx_SentSerialInput)

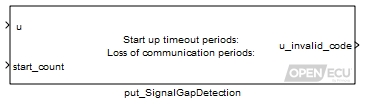

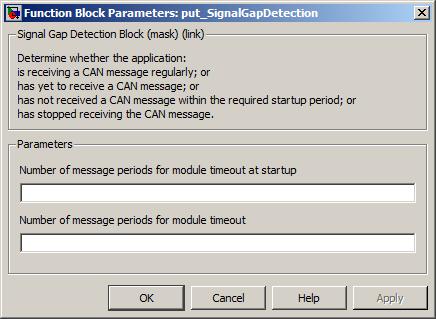

- 6.1.101. Signal gap detection (put_SignalGapDetection)

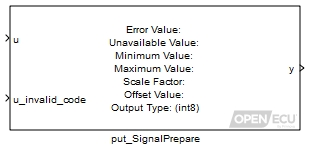

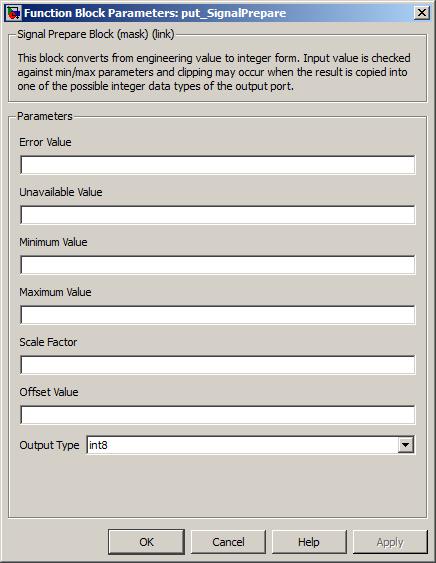

- 6.1.102. Signal prepare (put_SignalPrepare)

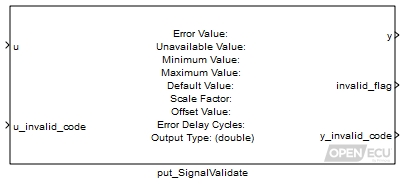

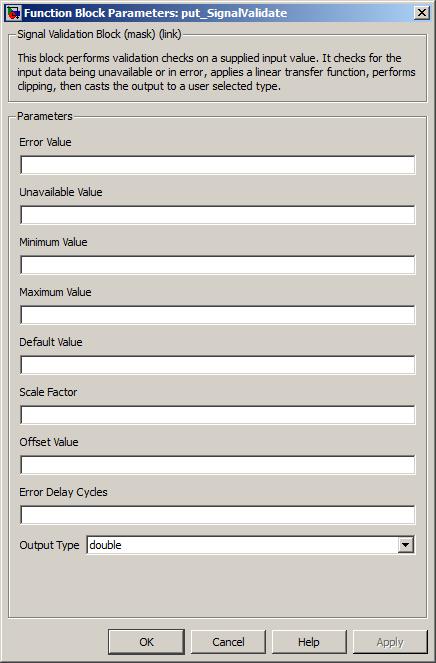

- 6.1.103. Signal validate (put_SignalValidate)

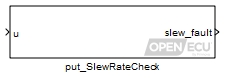

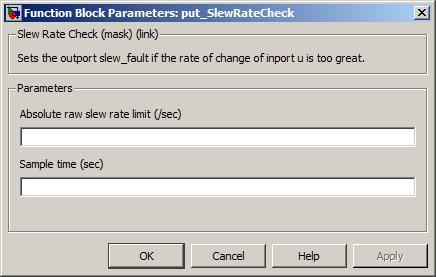

- 6.1.104. Slew rate check (put_SlewRateCheck)

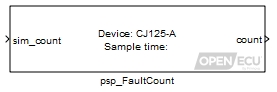

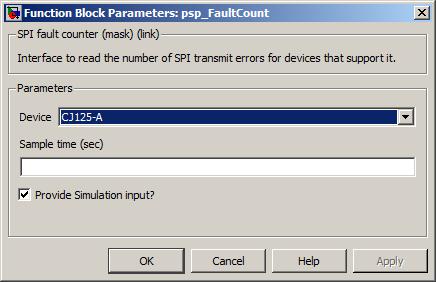

- 6.1.105. SPI communication fault count (psp_FaultCount)

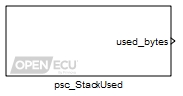

- 6.1.106. Stack used (psc_StackUsed)

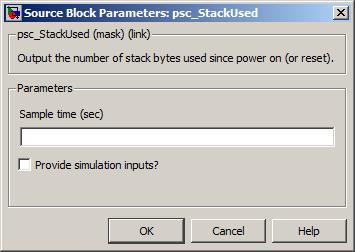

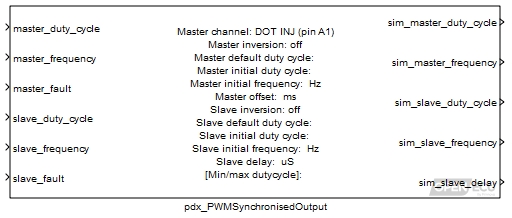

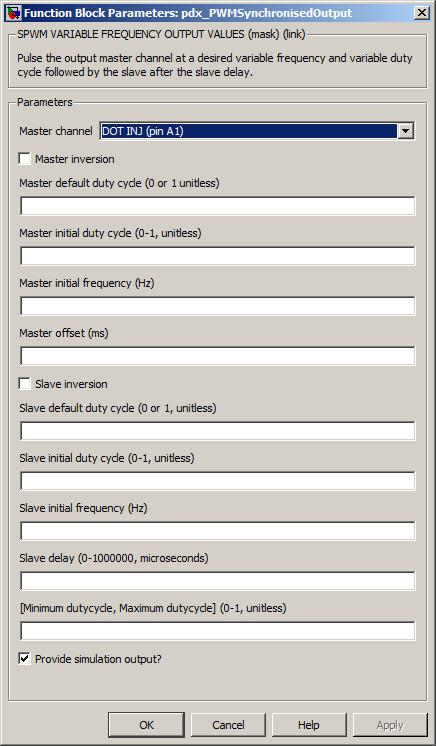

- 6.1.107. PWM output — variable frequency, synchronised (pdx_PWMSynchronisedOutput)

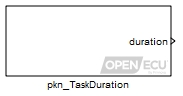

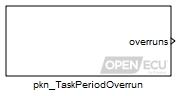

- 6.1.108. Task duration (pkn_TaskDuration)

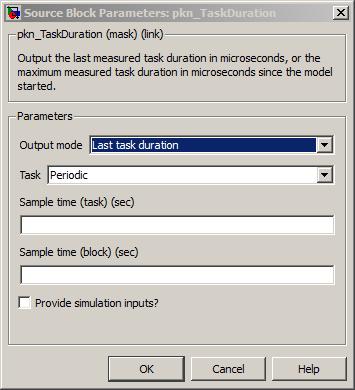

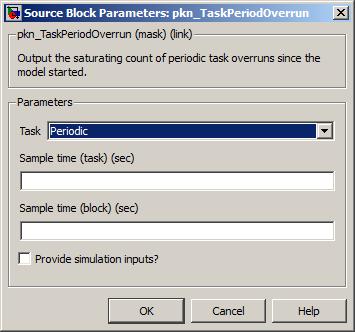

- 6.1.109. Task period overrun (pkn_TaskPeriodOverrun)

- 6.1.110. TargetLink Integration (ptl_TargetLinkSubsystem)

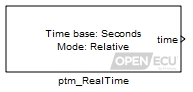

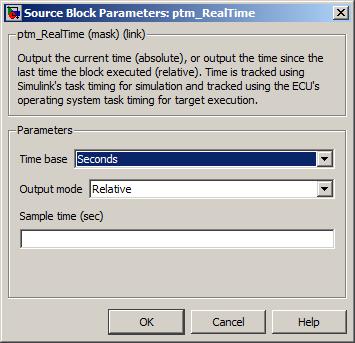

- 6.1.111. Time (real) (ptm_RealTime)

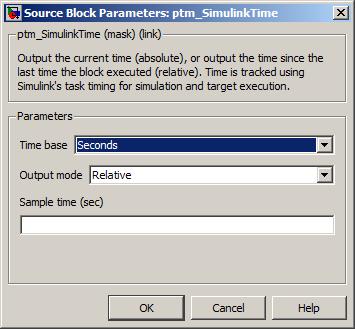

- 6.1.112. Time (Simulink) (ptm_SimulinkTime)

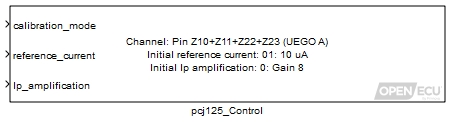

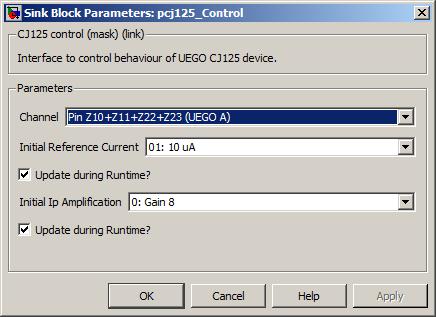

- 6.1.113. UEGO sensor control — CJ125 device (pcj125_Control)

- 6.1.114. Watchdog kick (psc_KickWatchdog)

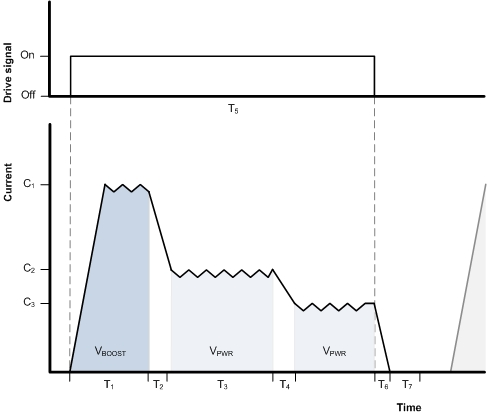

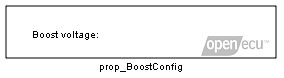

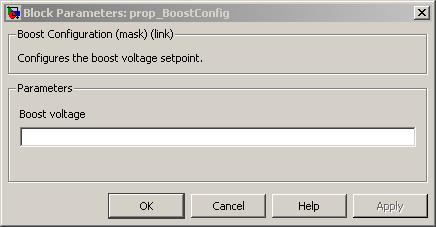

- 6.1.115. Waveform — configuration, boost voltage (prop_BoostConfig)

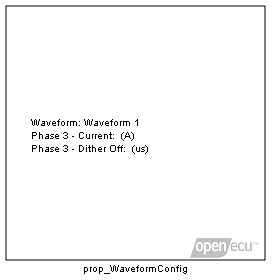

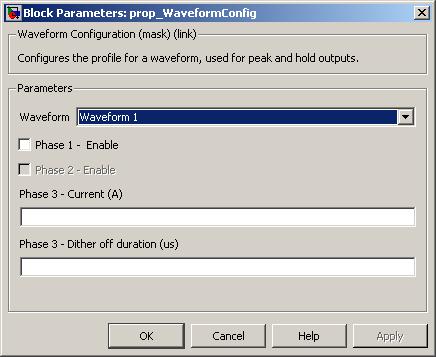

- 6.1.116. Waveform — configuration, phases (prop_WaveformConfig)

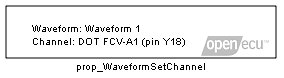

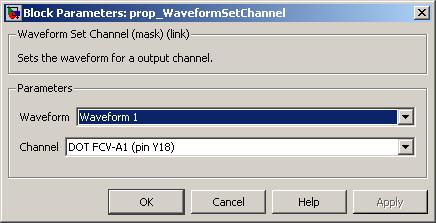

- 6.1.117. Waveform — set channel (prop_WaveformSetChannel)

- 6.2. Automatic ASAP2 entries

- 6.2.1. Boot build information

- 6.2.2. Reprogramming build information

- 6.2.3. Platform build information

- 6.2.4. Application build information

- 6.2.5. Application and library task timing information

- 6.2.6. Memory use information

- 6.2.7. Memory error correction events

- 6.2.8. Floating point conditions

- 6.2.9. J1939 related information

- 6.3. OpenECU software versioning

- 6.4. OpenECU commands

- 7. Angular detail

- 7.1. Engine position sensor processing

- 7.1.1. Crankshaft position sensor processing

- 7.1.2. Crankshaft position detection

- 7.1.3. Crankshaft zero degrees

- 7.1.4. Angle clock

- 7.1.5. Crank tooth identification

- 7.1.6. Crankshaft speed

- 7.1.7. Multiple crankshaft sensor inputs

- 7.1.8. Camshaft position sensor processing

- 7.1.9. Engine synchronisation modes

- 7.2. Engine TDC-firing events

- 7.3. Analogue input processing

- 7.4. Knock sensor processing

- 7.5. Scheduling injector outputs

- 7.6. Scheduling coil outputs

- 7.7. Scheduling digital outputs

- 7.8. Blockset reference

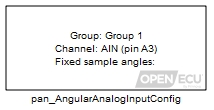

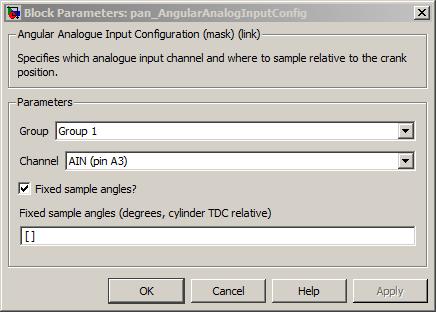

- 7.8.1. Analogue input — angular, configuration (pan_AngularAnalogInput_Config)

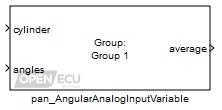

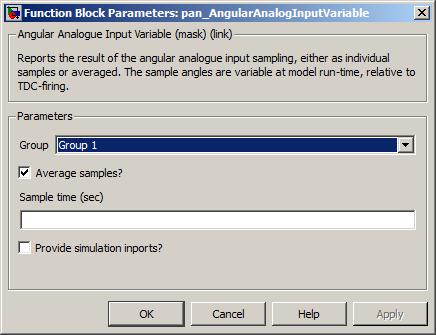

- 7.8.2. Analogue input — angular, variable relative angle (pan_AngularAnalogInputVariable)

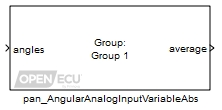

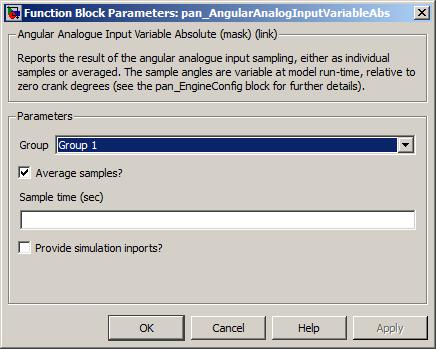

- 7.8.3. Analogue input — angular, variable absolute angle (pan_AngularAnalogInputVariableAbs)

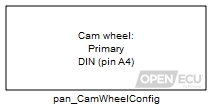

- 7.8.4. Cam wheel — configuration (pan_CamWheelConfig)

- 7.8.5. Cam wheel — digital input (pan_CamWheelDigitalInput)

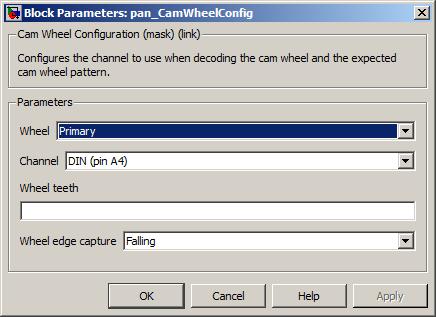

- 7.8.6. Cam wheel — movement (pan_CamWheelMovement)

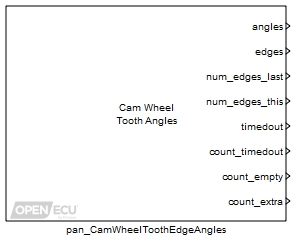

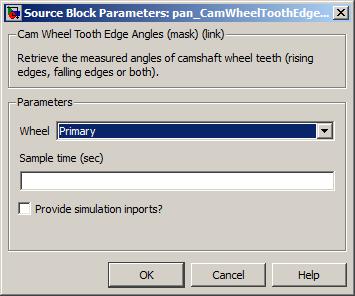

- 7.8.7. Cam wheel — tooth edge angles (pan_CamWheelToothEdgeAngles)

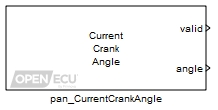

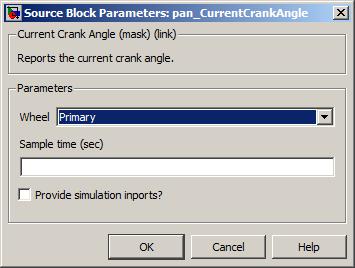

- 7.8.8. Crank wheel — angle (pan_CurrentCrankAngle)

- 7.8.9. Crank wheel — configuration (pan_CrankWheelConfig)

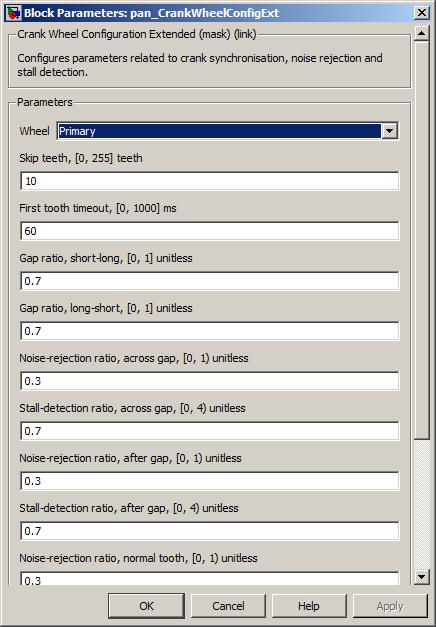

- 7.8.10. Crank wheel — extended configuration (pan_CrankWheelConfigExt)

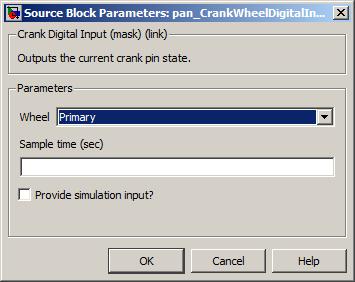

- 7.8.11. Crank wheel — digital input (pan_CrankWheelDigitalInput)

- 7.8.12. Crank wheel — decoding (pan_CrankWheelDecodeState)

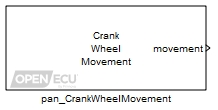

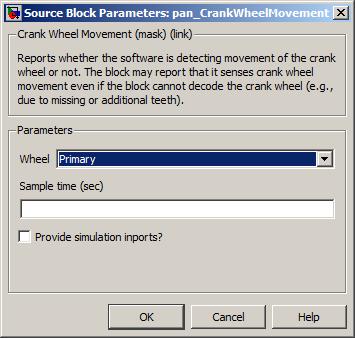

- 7.8.13. Crank wheel — movement (pan_CrankWheelMovement)

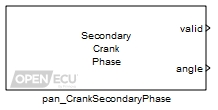

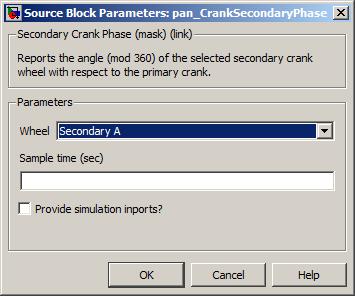

- 7.8.14. Crank wheel — secondary phase angle (pan_CrankSecondaryPhase)

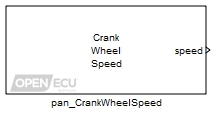

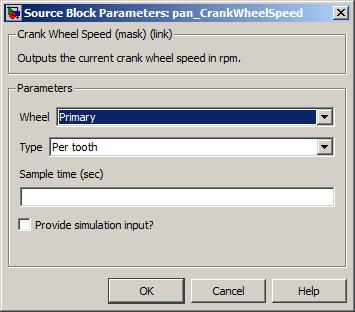

- 7.8.15. Crank wheel — speed (pan_CrankWheelSpeed)

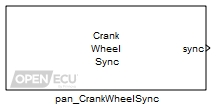

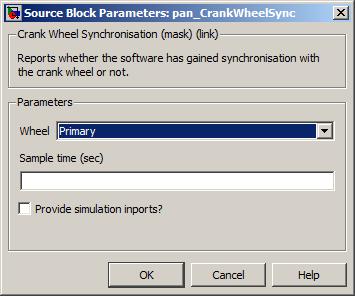

- 7.8.16. Crank wheel — synchronisation (pan_CrankWheelSync)

- 7.8.17. Crank wheel — sync point last (pan_CrankWheelSyncPointLast)

- 7.8.18. Crank wheel — sync point next (pan_CrankWheelSyncPointNext)

- 7.8.19. Crank wheel — sync point trigger (pan_CrankWheelSyncPointTrigger)

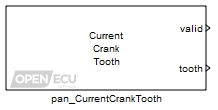

- 7.8.20. Crank wheel — tooth (pan_CurrentCrankTooth)

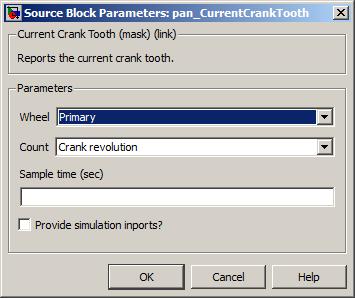

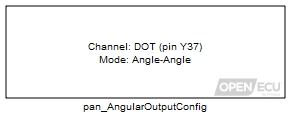

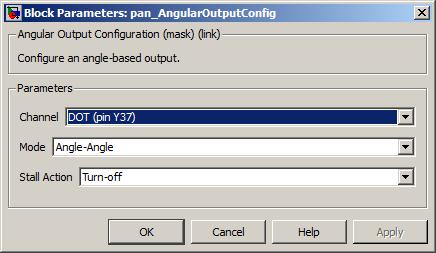

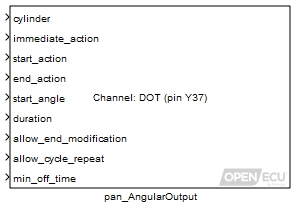

- 7.8.21. Digital output — angular configuration (pan_AngularOutputConfig)

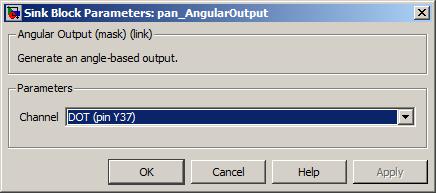

- 7.8.22. Digital output — angular digital (pan_AngularOutput)

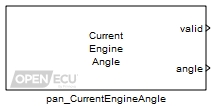

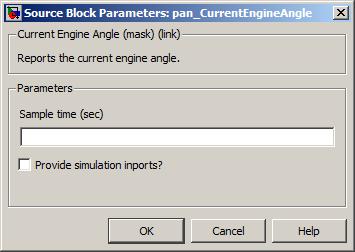

- 7.8.23. Engine angle (pan_CurrentEngineAngle)

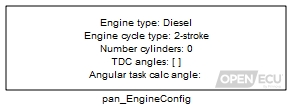

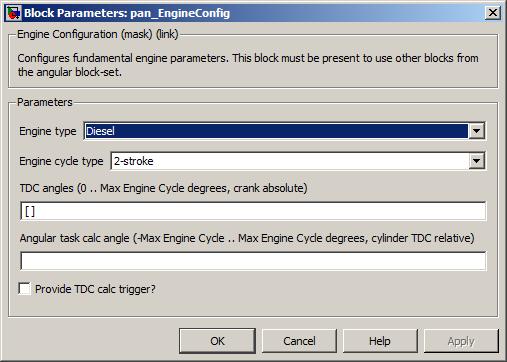

- 7.8.24. Engine configuration (pan_EngineConfig)

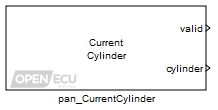

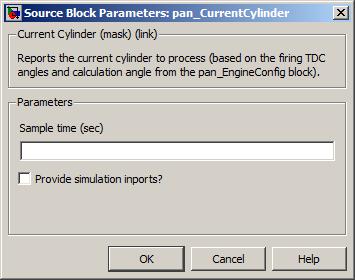

- 7.8.25. Engine cylinder (pan_CurrentCylinder)

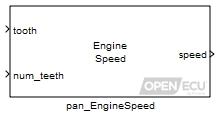

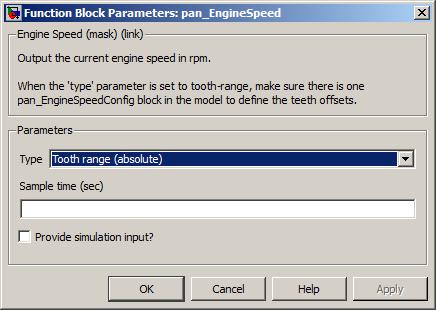

- 7.8.26. Engine speed (pan_EngineSpeed)

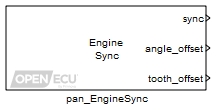

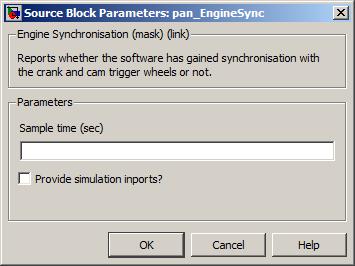

- 7.8.27. Engine synchronisation (pan_EngineSync)

- 7.8.28. Engine synchronisation — declare mode (pan_EngineDeclareSync)

- 7.8.29. Engine synchronisation — declare loss of synchronisation (pan_EngineLoseSync)

- 7.8.30. Engine tooth (pan_CurrentEngineTooth)

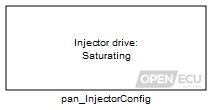

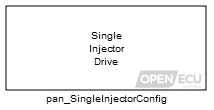

- 7.8.31. Injection configuration — multiple outputs (pan_InjectorConfig)

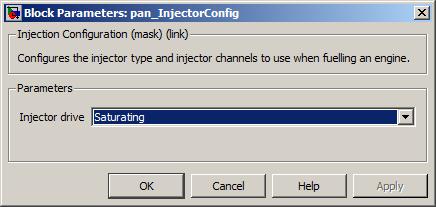

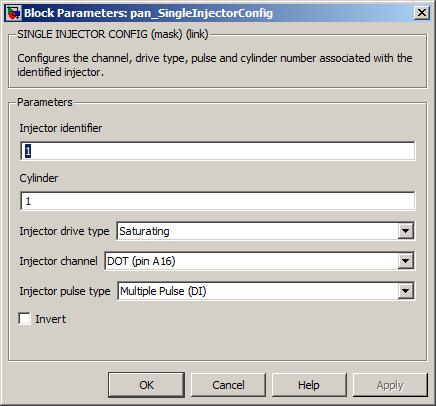

- 7.8.32. Injection configuration — single output (pan_SingleInjectorConfig)

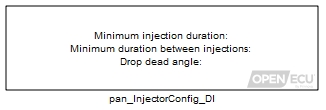

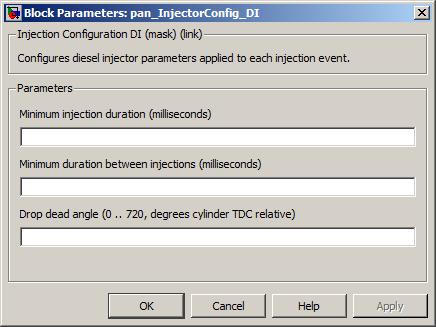

- 7.8.33. Injection configuration — direct injection (pan_InjectorConfig_DI)

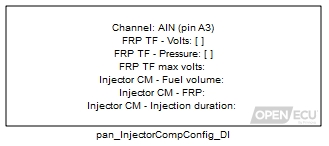

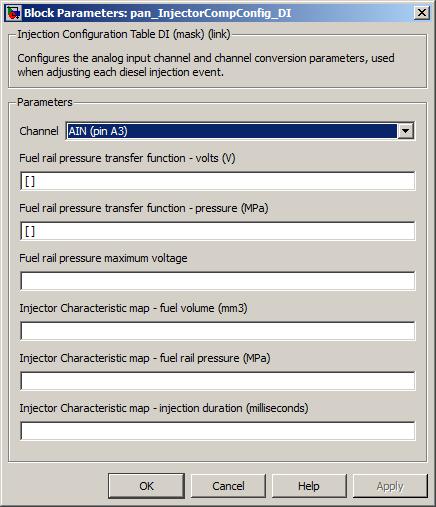

- 7.8.34. Injection configuration — fuel rail pressure compensation (pan_InjectorCompConfig_DI)

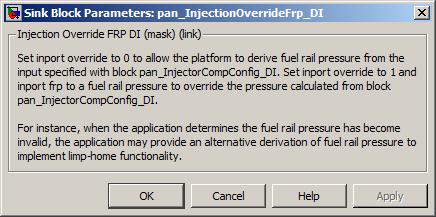

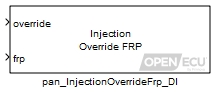

- 7.8.35. Injection direct — fuel rail pressure override (pan_InjectionOverrideFrp_DI)

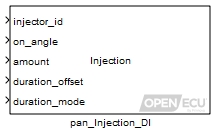

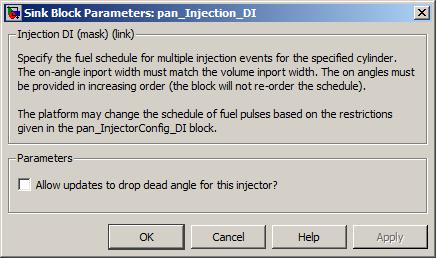

- 7.8.36. Injection direct — set schedule (pan_Injection_DI)

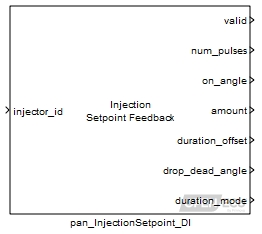

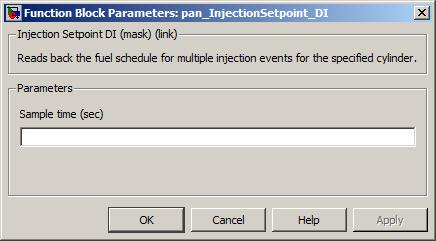

- 7.8.37. Injection direct — setpoint feedback (pan_InjectionSetpoint_DI)

- 7.8.38. Injection direct — event feedback (pan_InjectionFeedback_DI)

- 7.8.39. Injection port — initial fuel pulse (pan_InitialInjection_PI)

- 7.8.40. Injection port — set schedule (pan_Injection_PI)

- 7.8.41. Injection port — update injection schedule (pan_UpdateInjection_PI)

- 7.8.42. Injection port — setpoint feedback (pan_InjectionSetpoint_PI)

- 7.8.43. Injection port — event feedback (pan_InjectionFeedback_PI)

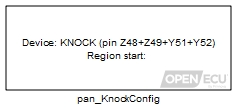

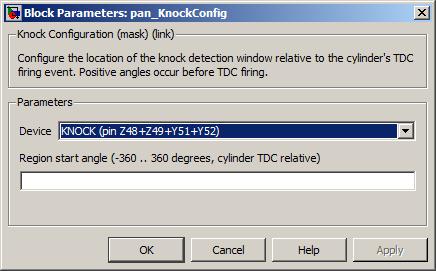

- 7.8.44. Knock configuration (pan_KnockConfig)

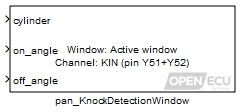

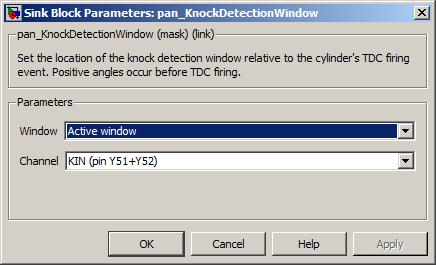

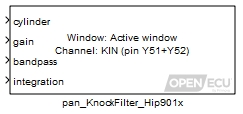

- 7.8.45. Knock detection window (pan_KnockDetectionWindow)

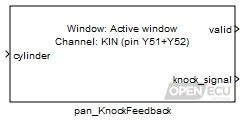

- 7.8.46. Knock feedback (pan_KnockFeedback)

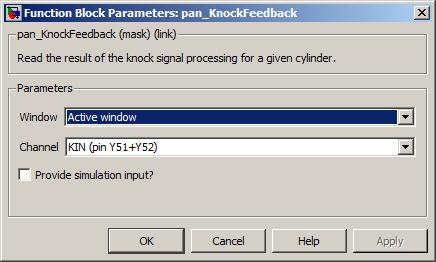

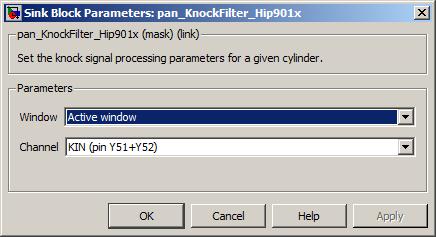

- 7.8.47. Knock filter — HIP901x (pan_KnockFilter_Hip901x)

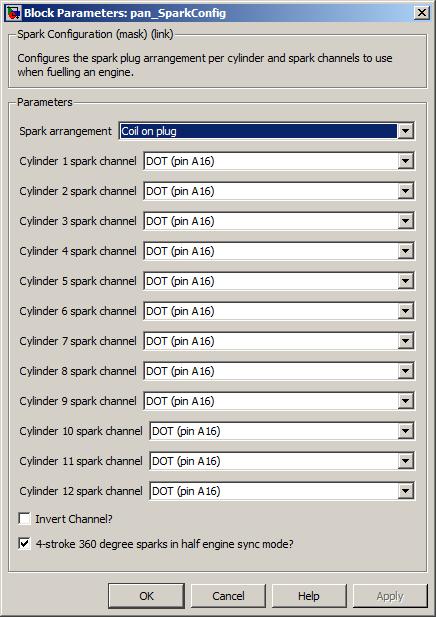

- 7.8.48. Spark configuration (pan_SparkConfig)

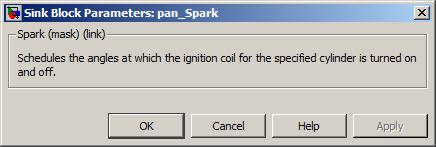

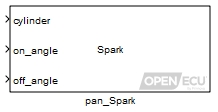

- 7.8.49. Spark (pan_Spark)

- 7.8.50. Spark feedback (pan_SparkFeedback)

- 7.8.51. Waveform — configuration, boost voltage (prop_BoostConfig)

- 7.8.52. Waveform — configuration, phases (prop_WaveformConfig)

- 7.8.53. Waveform — set channel (prop_WaveformSetChannel)

- 8. Extended diagnostics functions

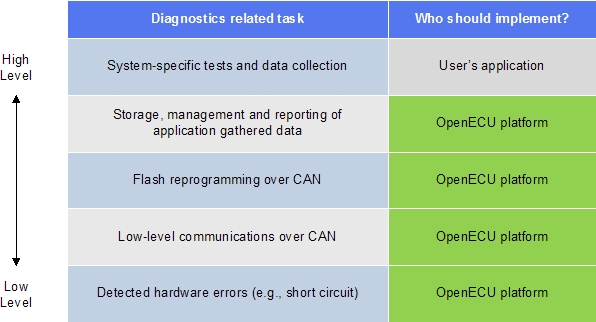

- 8.1. Introduction to Diagnostics

- 8.2. Diagnostic Legislation

- 8.3. Approach

- 8.4. Diagnostic trouble codes and freeze-frames

- 8.5. Diagnostic monitors, tests and performance ratios

- 8.6. Worked example — building a diagnostic system

- 8.7. Extended diagnostic Simulink blocks

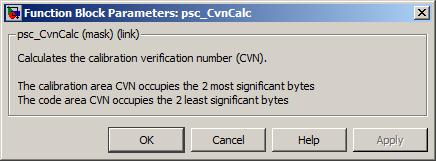

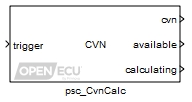

- 8.7.1. Calibration verification number (CVN) (psc_CvnCalc)

- 8.7.2. DTC clear all (pdtc_ClearAll)

- 8.7.3. DTC clear all if active (pdtc_ClearAllIfActive)

- 8.7.4. DTC clear all if inactive (pdtc_ClearAllIfInactive)

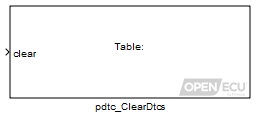

- 8.7.5. DTC match and clear (pdtc_ClearDtcs)

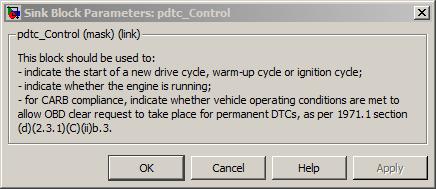

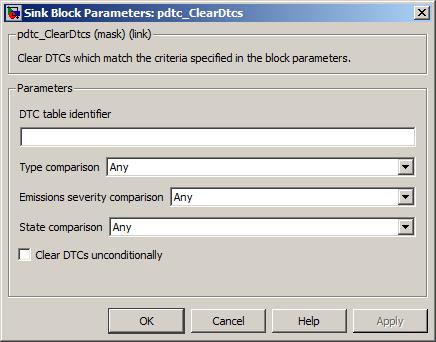

- 8.7.6. DTC control (pdtc_Control)

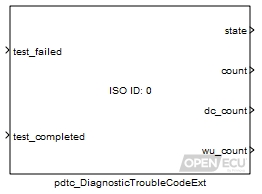

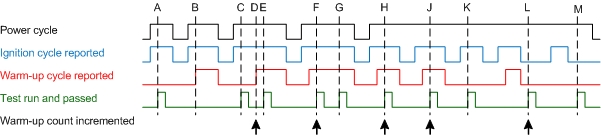

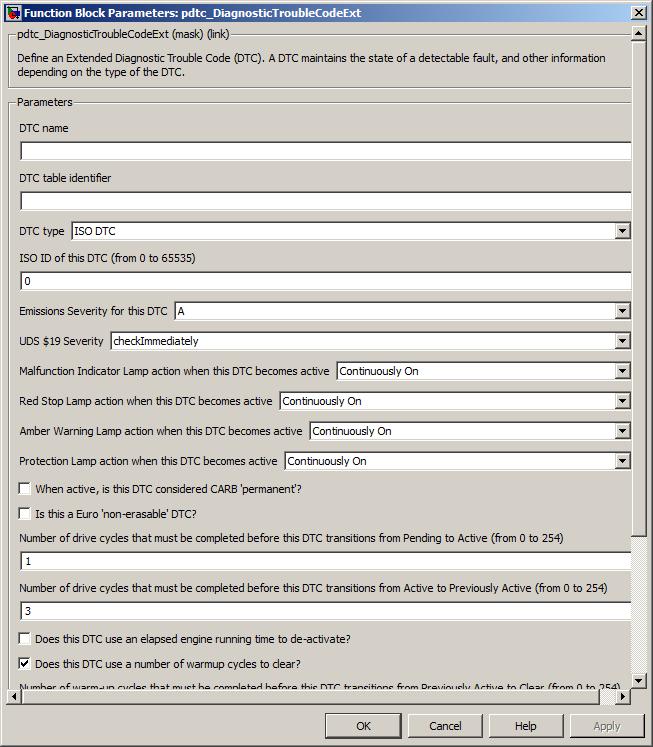

- 8.7.7. DTC diagnostic trouble code (extended) (pdtc_DiagnosticTroubleCodeExt)

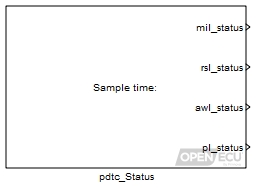

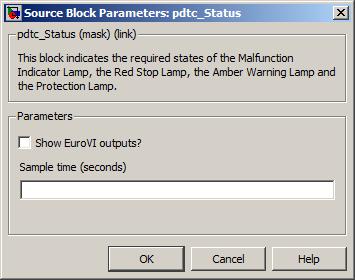

- 8.7.8. DTC lamp states (pdtc_Status)

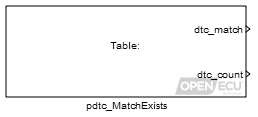

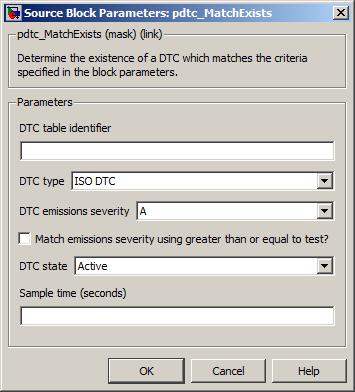

- 8.7.9. DTC match exists (pdtc_MatchExists)

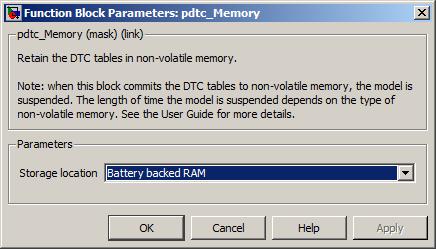

- 8.7.10. DTC memory update (pdtc_Memory)

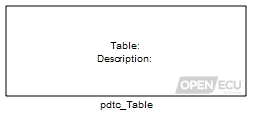

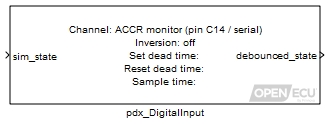

- 8.7.11. DTC table definition (pdtc_Table)

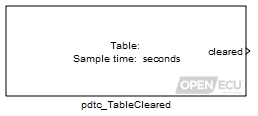

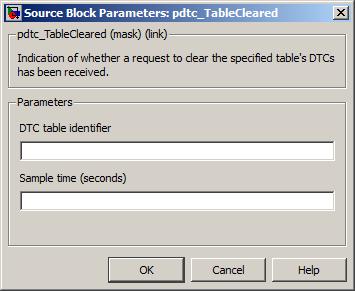

- 8.7.12. DTC table cleared indication (pdtc_TableCleared)

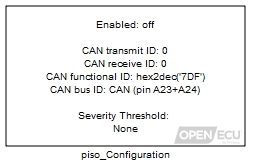

- 8.7.13. ISO configuration (piso_Configuration)

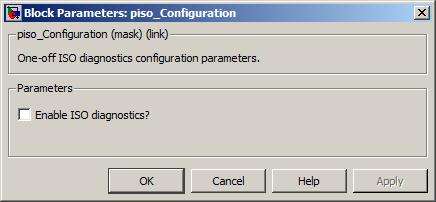

- 8.7.14. ISO security permissions (pdg_Permissions)

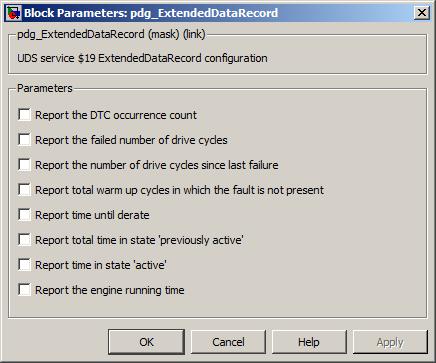

- 8.7.15. ISO DTC extended data records (pdg_ExtendedDataRecord)

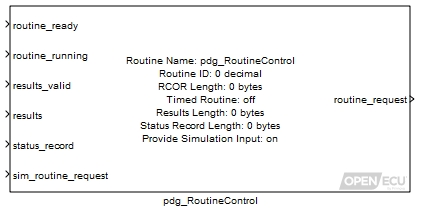

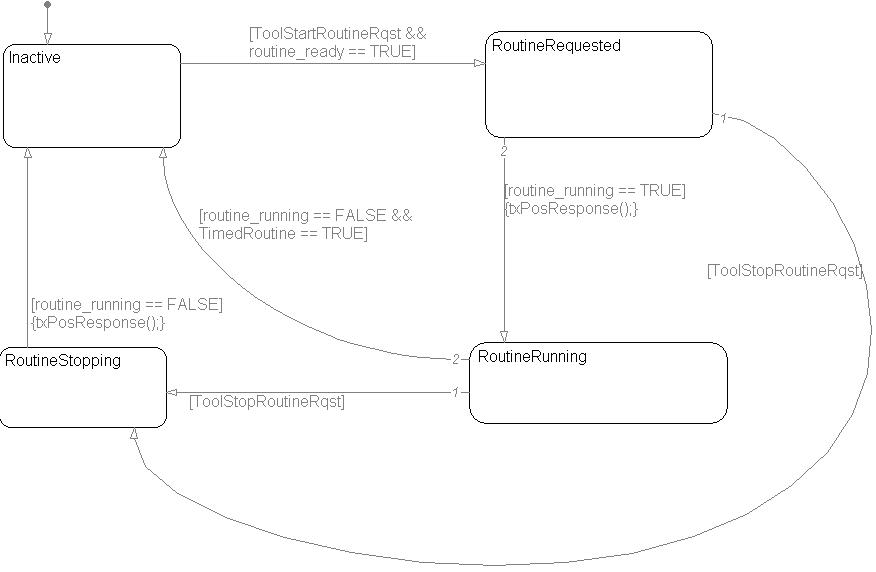

- 8.7.16. Routine control (pdg_RoutineControl)

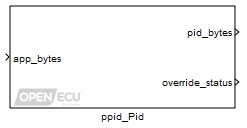

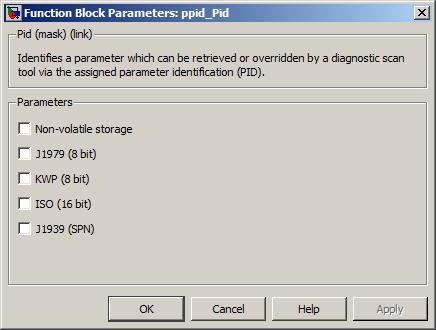

- 8.7.17. Parameter identifier (ppid_Pid)

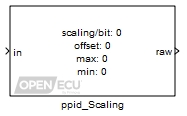

- 8.7.18. Parameter identifier scaling (ppid_Scaling)

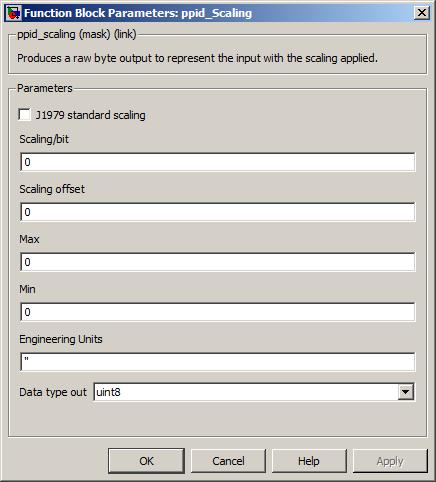

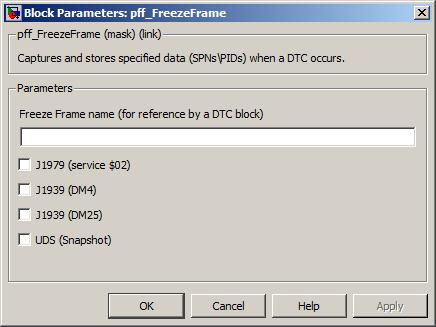

- 8.7.19. Freeze frame (pff_FreezeFrame)

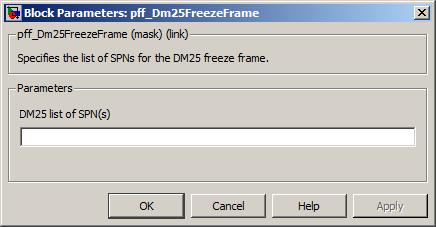

- 8.7.20. DM25 freeze frame (pff_Dm25FreezeFrame)

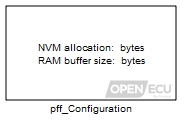

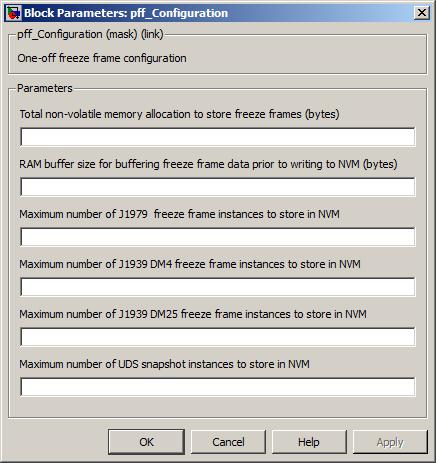

- 8.7.21. Freeze frame configuration (pff_Configuration)

- 8.7.22. J1939 configuration (pj1939_Configuration)

- 8.7.23. J1939 channel configuration (pj1939_ChannelConfiguration)

- 8.7.24. J1939 Transmit DTC DM (pj1939_TransmitDtcDm)

- 8.7.25. J1939 DM1 receive (pj1939_Dm1Receive)

- 8.7.26. J1939 DM1 decode DTC (pj1939_Dm1DecodeDtc)

- 8.7.27. J1939 DM1 transmit (pj1939_Dm1Transmit)

- 8.7.28. J1939 DM2 receive (pj1939_Dm2Receive)

- 8.7.29. J1939 DM2 decode DTC (pj1939_Dm2DecodeDtc)

- 8.7.30. J1939 DM2 transmit (pj1939_Dm2Transmit)

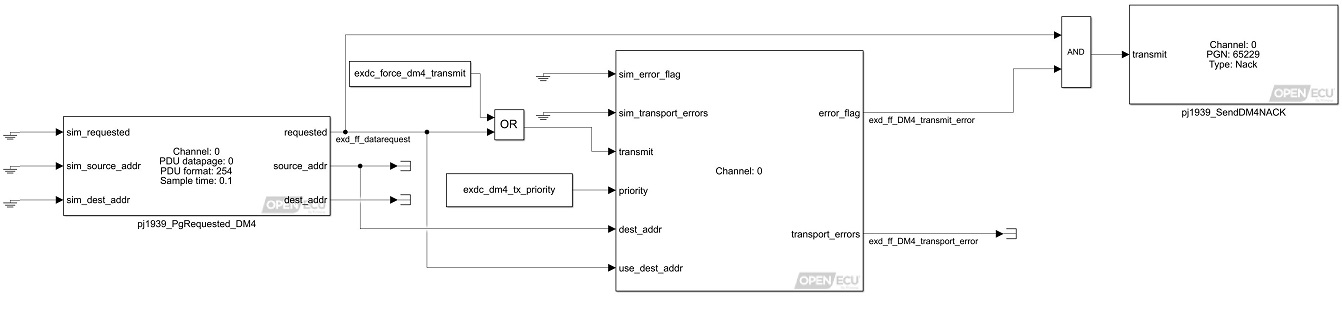

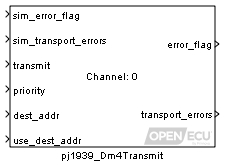

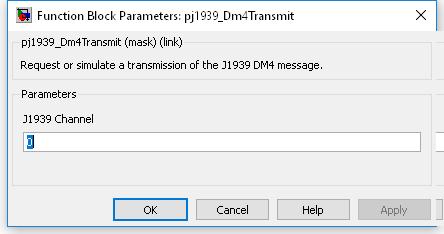

- 8.7.31. J1939 DM4 transmit (pj1939_Dm4Transmit)

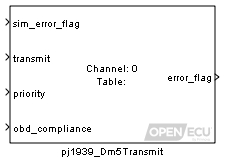

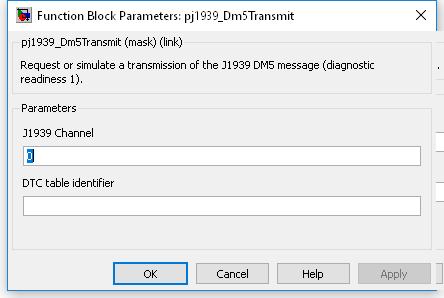

- 8.7.32. J1939 DM5 transmit (pj1939_Dm5Transmit)

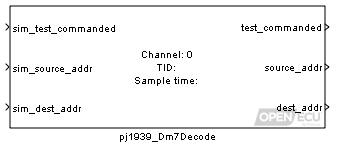

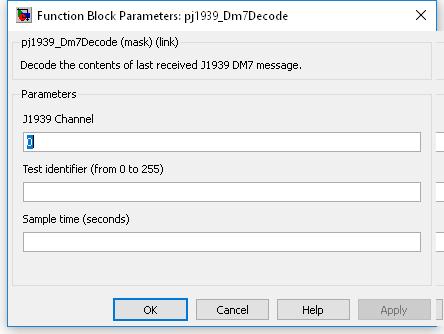

- 8.7.33. J1939 DM7 decode (pj1939_Dm7Decode)

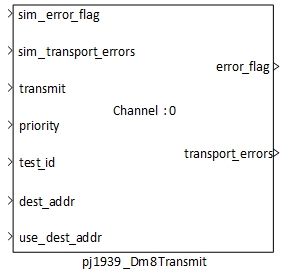

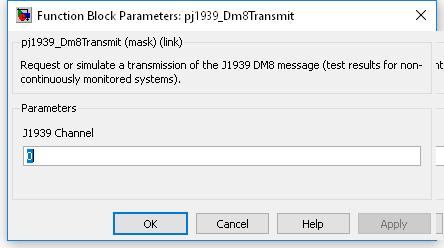

- 8.7.34. J1939 DM8 transmit (pj1939_Dm8Transmit)

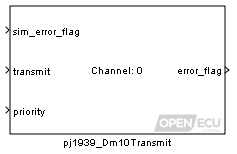

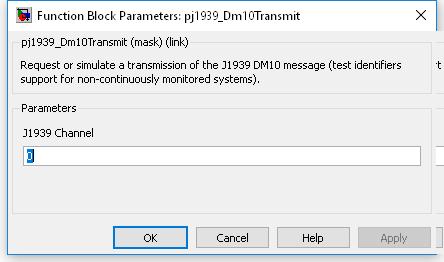

- 8.7.35. J1939 DM10 transmit (pj1939_Dm10Transmit)

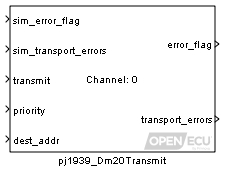

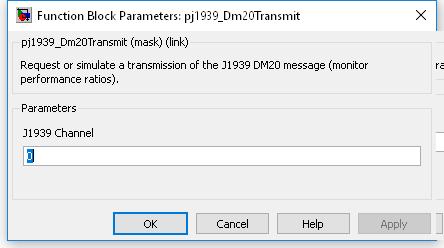

- 8.7.36. J1939 DM20 transmit (pj1939_Dm20Transmit)

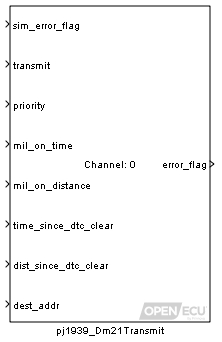

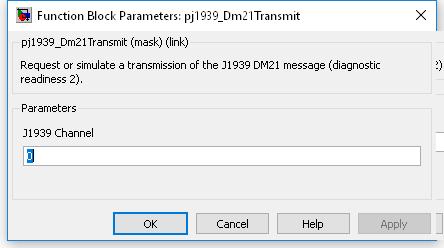

- 8.7.37. J1939 DM21 transmit (pj1939_Dm21Transmit)

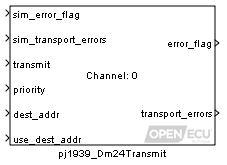

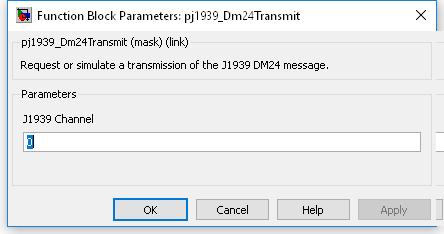

- 8.7.38. J1939 DM24 transmit (pj1939_Dm24Transmit)

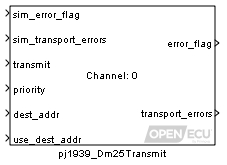

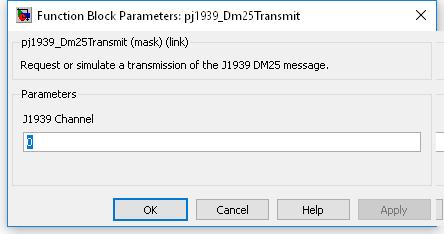

- 8.7.39. J1939 DM25 transmit (pj1939_Dm25Transmit)

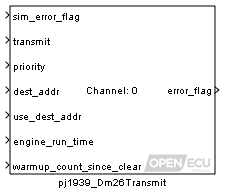

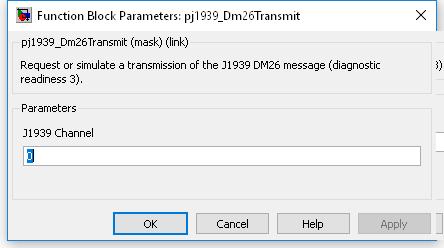

- 8.7.40. J1939 DM26 transmit (pj1939_Dm26Transmit)

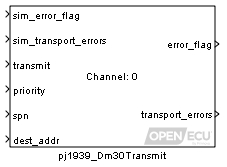

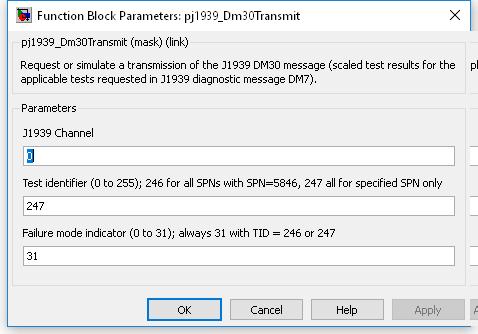

- 8.7.41. J1939 DM30 transmit (pj1939_Dm30Transmit)

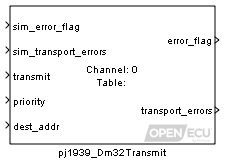

- 8.7.42. J1939 DM32 transmit (pj1939_Dm32Transmit)

- 8.7.43. J1939 DM33 transmit (pj1939_Dm33Transmit)

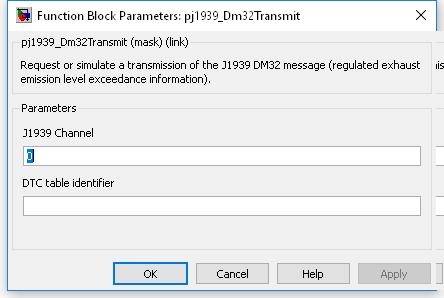

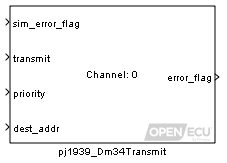

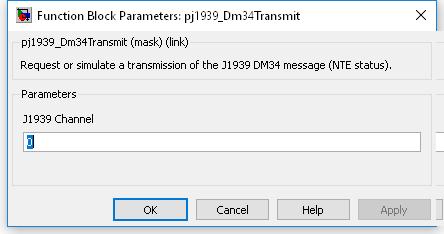

- 8.7.44. J1939 DM34 transmit (pj1939_Dm34Transmit)

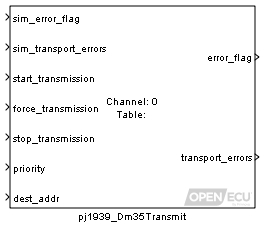

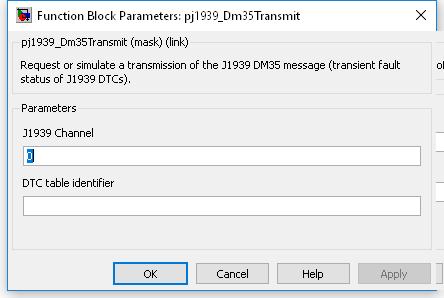

- 8.7.45. J1939 DM35 transmit (pj1939_Dm35Transmit)

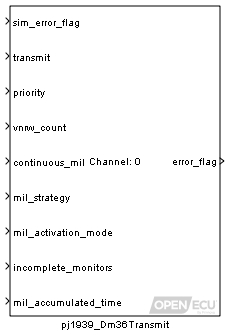

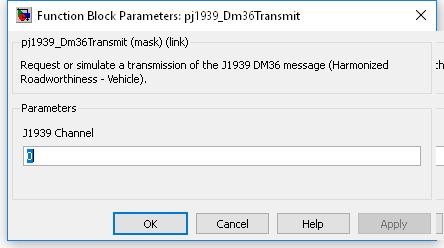

- 8.7.46. J1939 DM36 transmit (pj1939_Dm36Transmit)

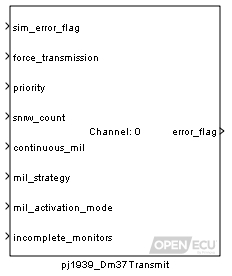

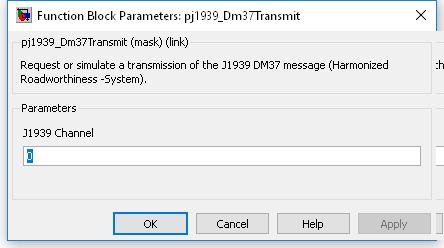

- 8.7.47. J1939 DM37 transmit (pj1939_Dm37Transmit)

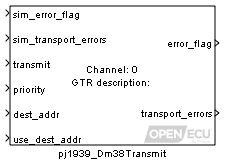

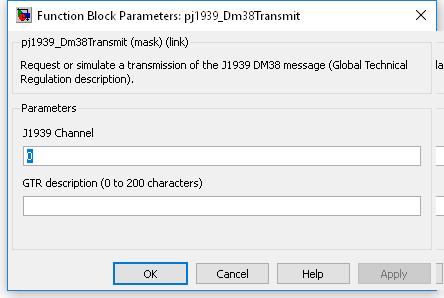

- 8.7.48. J1939 DM38 transmit (pj1939_Dm38Transmit)

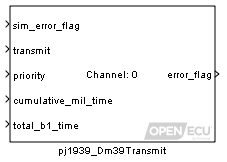

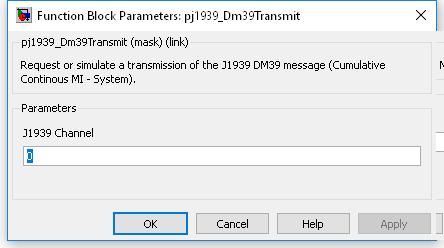

- 8.7.49. J1939 DM39 transmit (pj1939_Dm39Transmit)

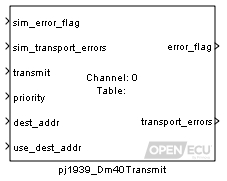

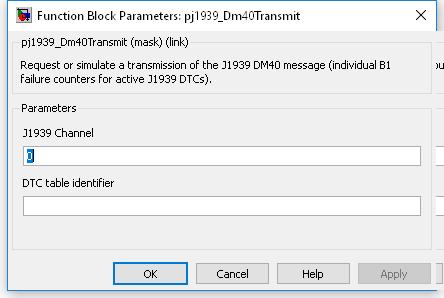

- 8.7.50. J1939 DM40 transmit (pj1939_Dm40Transmit)

- 8.7.51. J1939 parameter group receive message (pj1939_PgReceive)

- 8.7.52. J1939 parameter group requested (pj1939_PgRequested)

- 8.7.53. J1939 parameter group transmit (pj1939_PgTransmit)

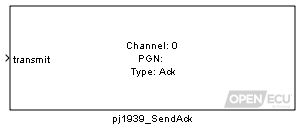

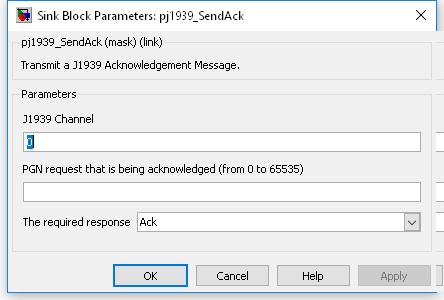

- 8.7.54. J1939 send acknowledgement message (pj1939_SendAck)

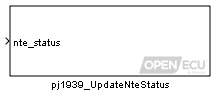

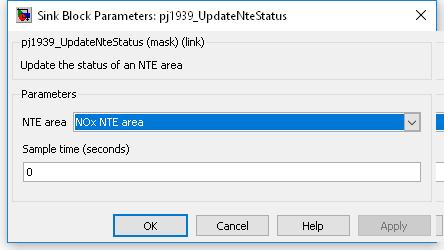

- 8.7.55. J1939 update NTE status (pj1939_UpdateNteStatus)

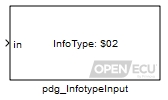

- 8.7.56. J1979 service $09 Infotype input (pdg_InfotypeInput)

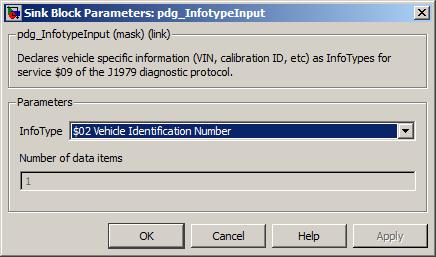

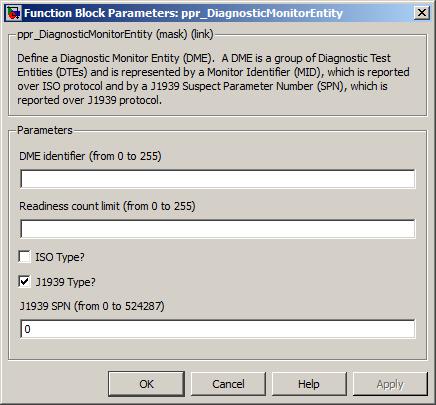

- 8.7.57. Diagnostic monitor entity (ppr_DiagnosticMonitorEntity)

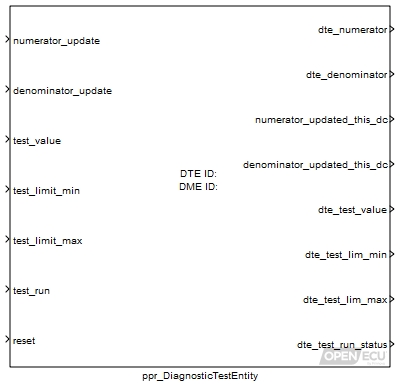

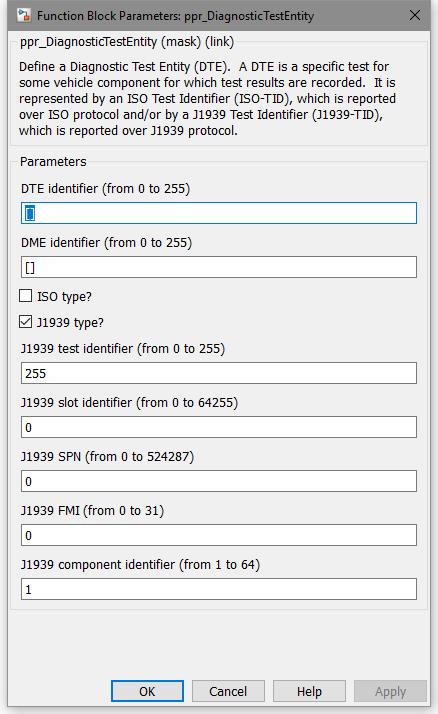

- 8.7.58. Diagnostic test entity (ppr_DiagnosticTestEntity)

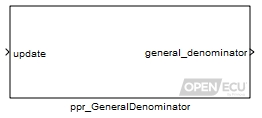

- 8.7.59. General denominator (ppr_GeneralDenominator)

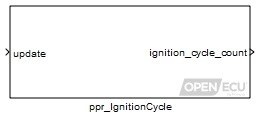

- 8.7.60. Ignition cycle (ppr_IgnitionCycle)

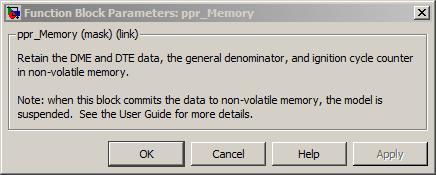

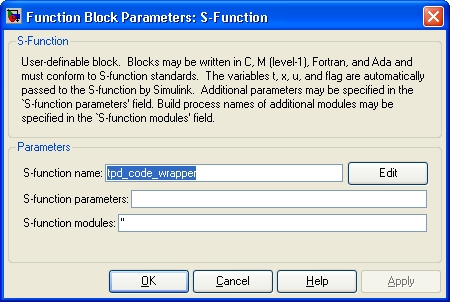

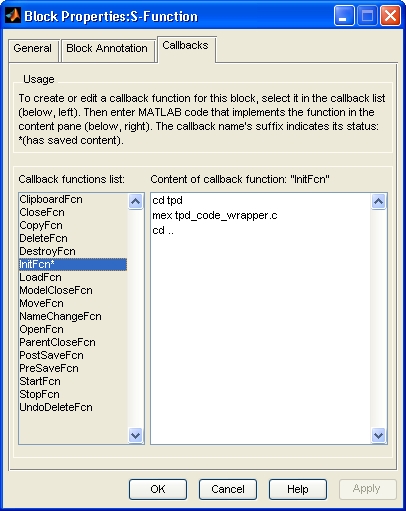

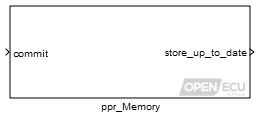

- 8.7.61. PPR memory update (ppr_Memory)

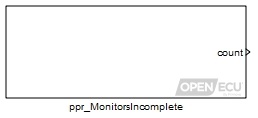

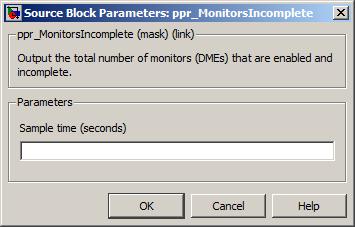

- 8.7.62. Monitors incomplete count (ppr_MonitorsIncomplete)

- A. Reference documentation

- B. Supporting tools

- C. Examples

- D. Memory configurations

- E. ASAP2 compliance

- F. CCP compliance

- G. CCP troubleshooting guide

- H. Data dictionary tool errors

- I. Change log

- J. Glossary of terms

- K. Contact information

List of Figures

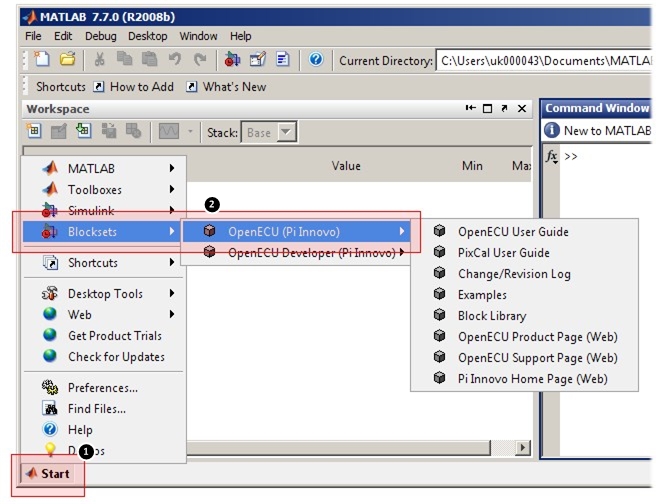

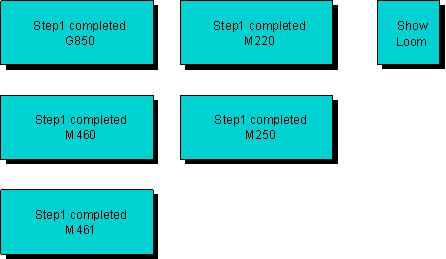

- 3.1. OpenECU integrated with MATLAB's launch pad

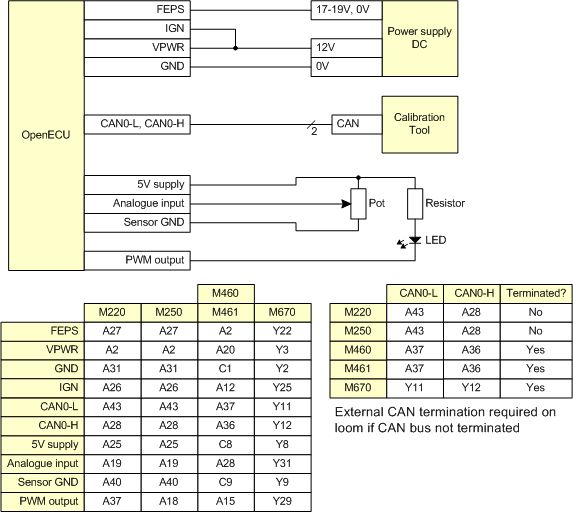

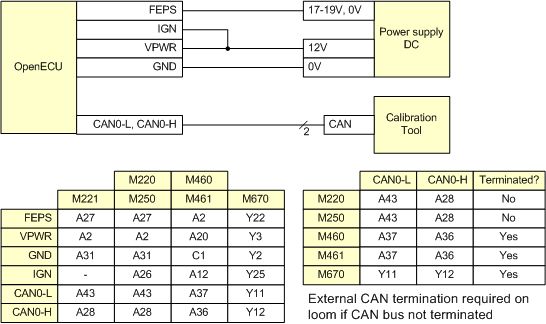

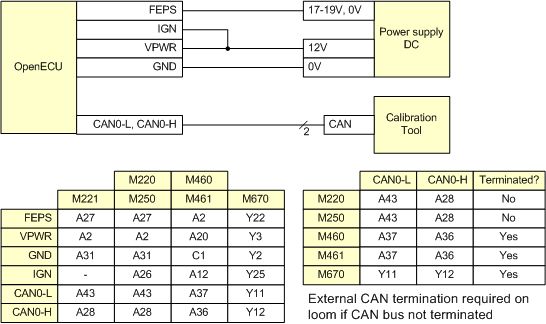

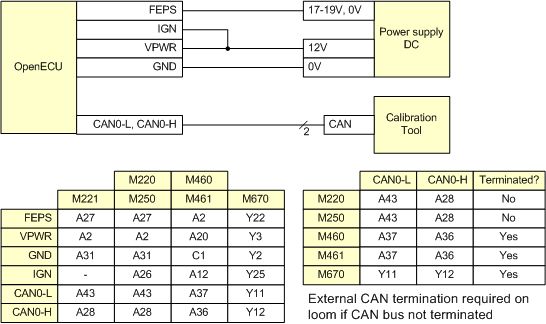

- 3.2. Quick start loom

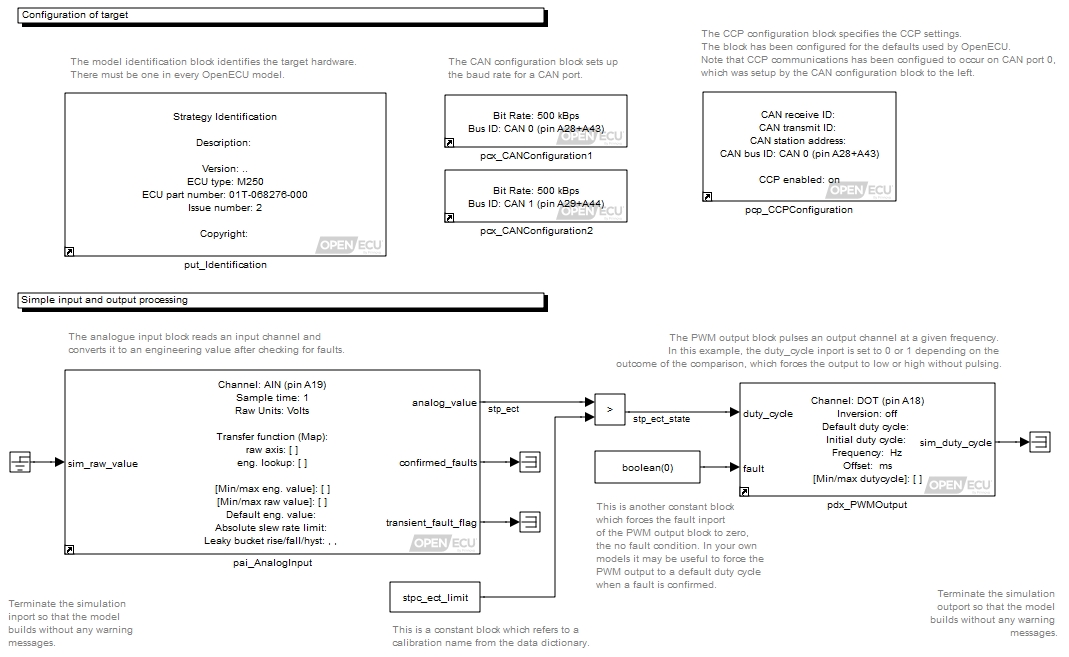

- 3.3. Connected quick start model

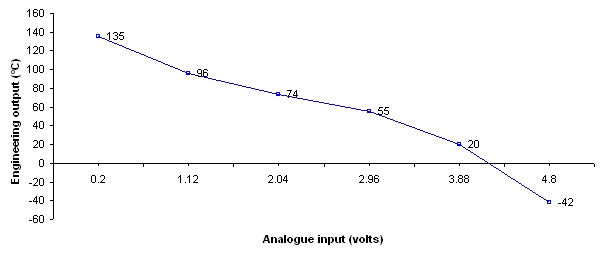

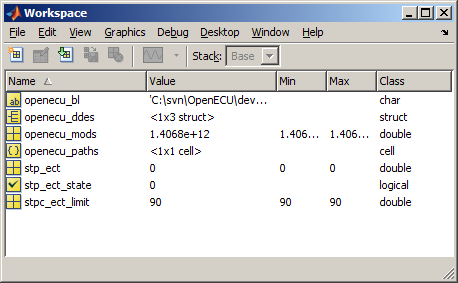

- 3.4. Analogue input transfer function

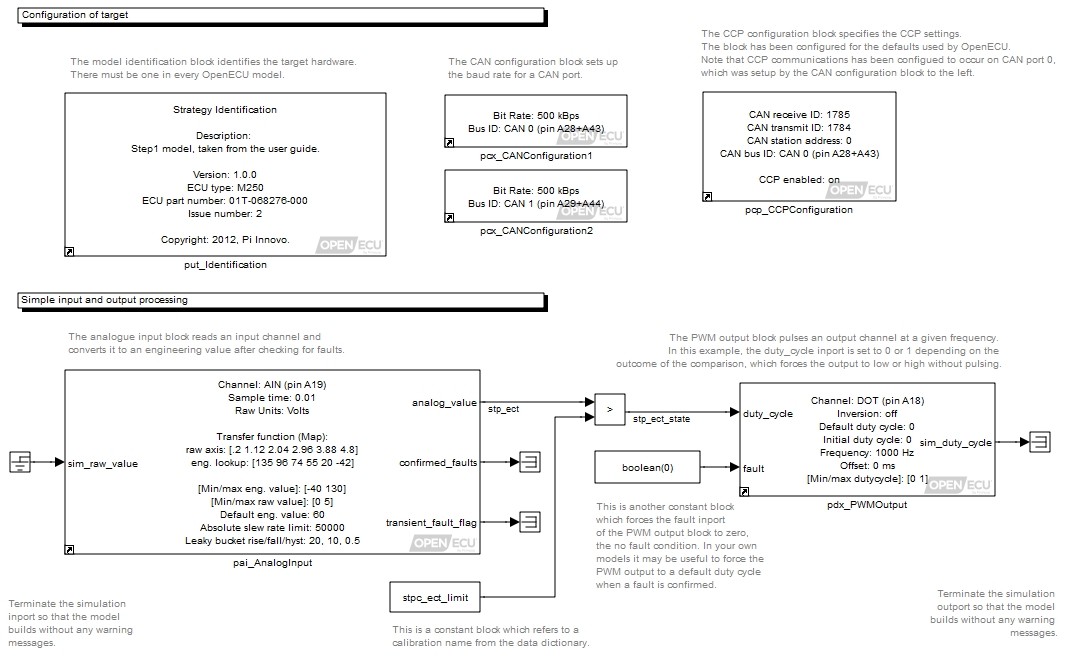

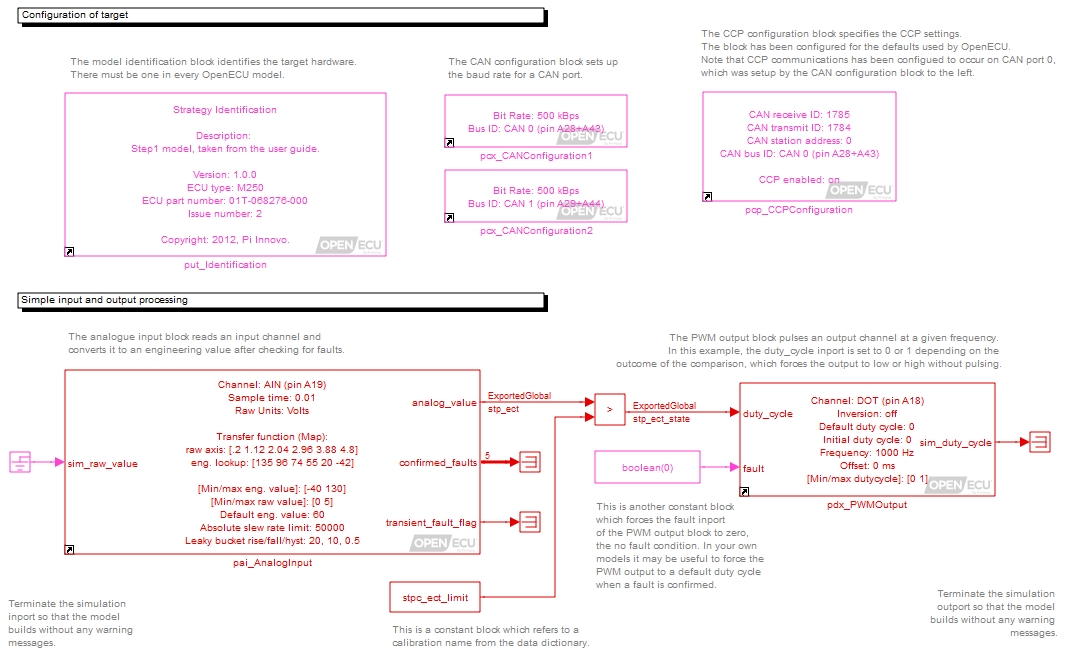

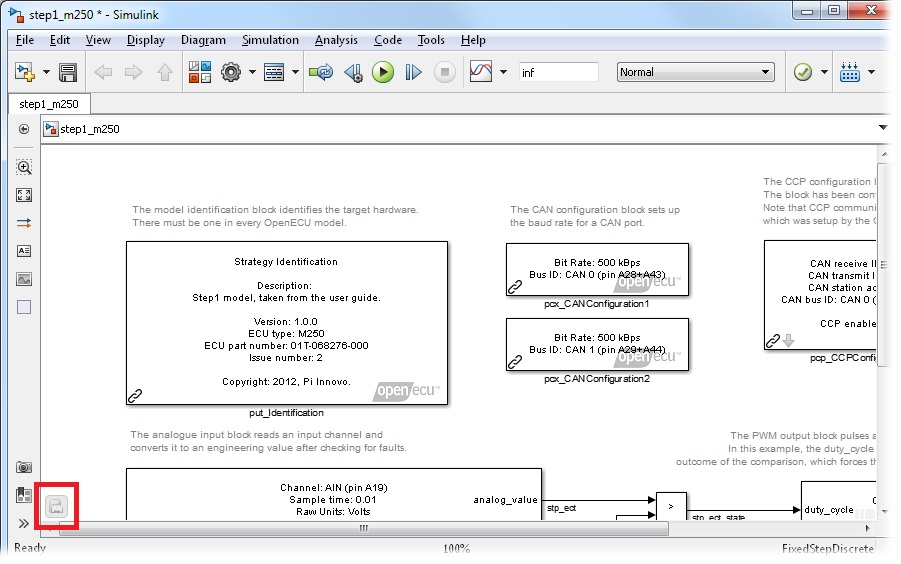

- 3.5. Configured quick start model

- 3.6. Updated quick start model

- 4.1. OpenECU integrated with Window's Start button

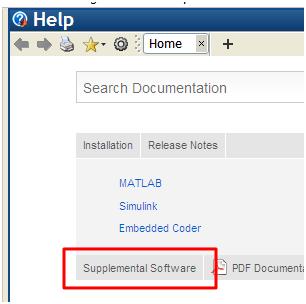

- 4.2. OpenECU integrated with MATLAB's help system (R2015a - R2015b)

- 4.3. OpenECU integrated with MATLAB's help system (R2016a - R2020a)

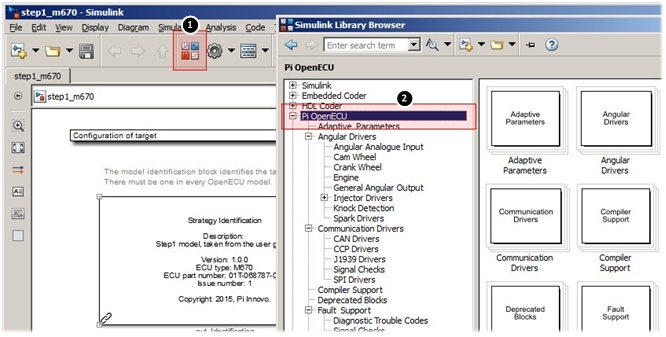

- 4.4. OpenECU integrated with MATLAB's library browser (R2015a - R2020a)

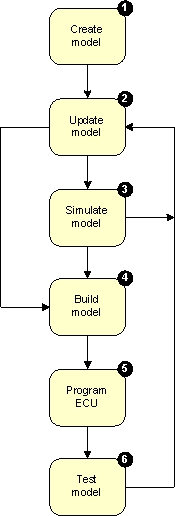

- 4.5. Example development pattern for modelling an application

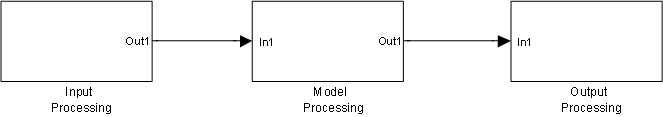

- 4.6. Breaking the input and output processing from the application

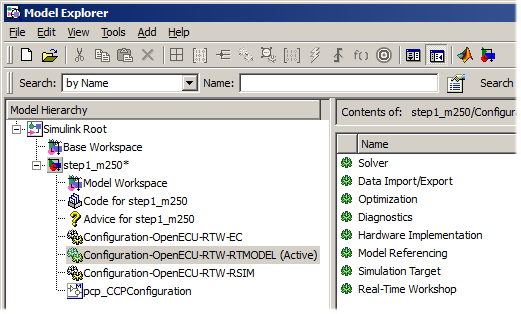

- 4.7. Simulink's Model Explorer showing OpenECU configuration sets

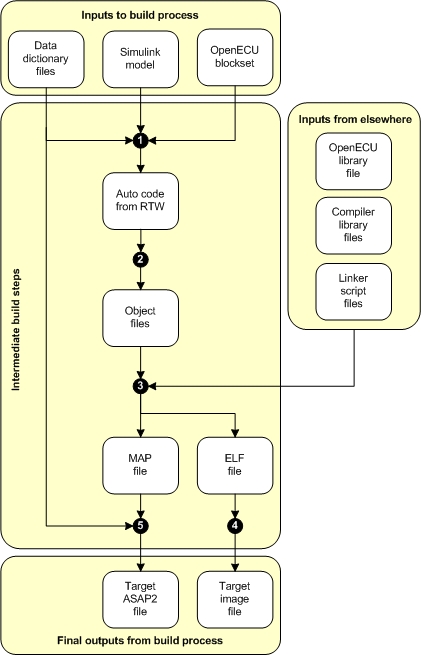

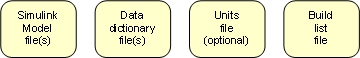

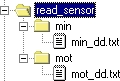

- 4.8. Building an application (in outline)

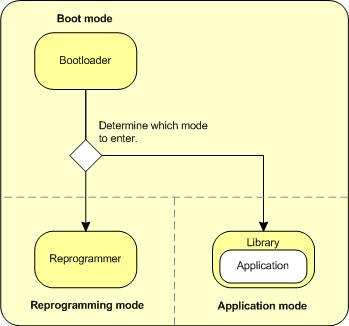

- 4.9. System modes

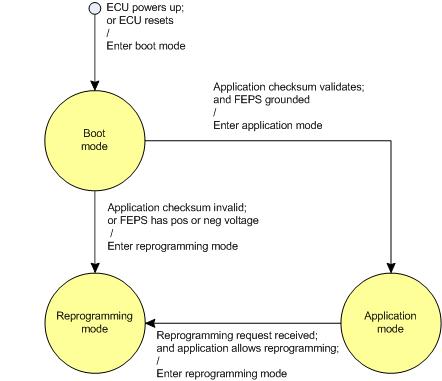

- 4.10. System modes for M220, M250, M460 and M461

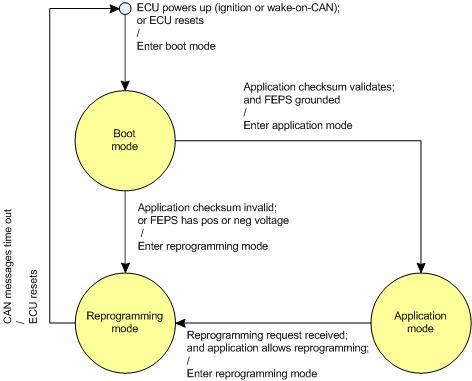

- 4.11. System modes for M110, M221 and M670

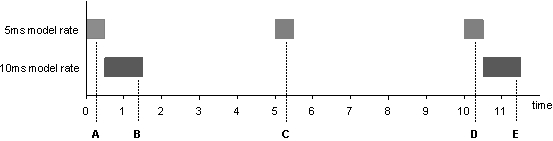

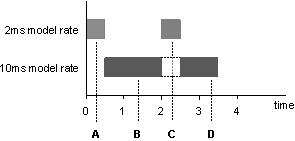

- 4.12. Signal update rates

- 4.13. Signal update rates

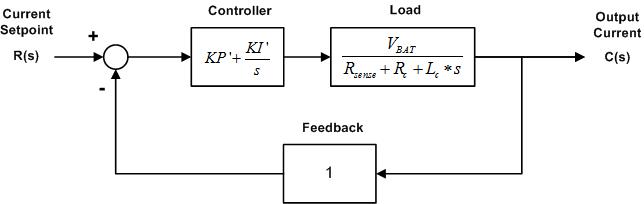

- 6.1. TLE8242-2 constant current control diagram

- 6.2. TLE8242-2 KP and KI equations

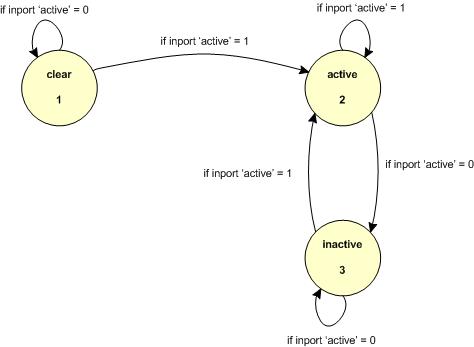

- 6.3. J1939 DTC states

- 6.4. Sector configuration for a 3 phase hall input - 60° spacing

- 6.5. Sector output encoding

- 6.6. Sensor outputs with 60° spacing

- 6.7. Sector configuration and outputs for 120° sensor spacing

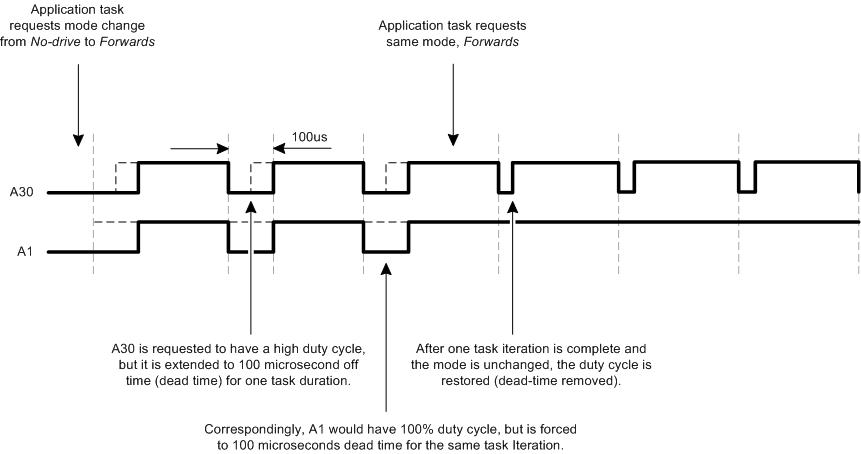

- 6.8. Output of H-Bridge during mode transition

- 6.9. Quadrature encoder and generated signals

- 6.10. Direction of encoder and generated signals

- 6.11. Pulse count example

- 6.12. Quadrature encoder and generated signals

- 6.13. Direction of encoder and generated signals

- 6.14. Pulse count example

- 6.15. Disabling naming convention

- 6.16. Disabling Simulink ASAP2 generation

- 6.17. Example time-line to explain the ptm_RealTime block

- 6.18. Example time-line to explain the ptm_SimulinkTime block

- 6.19. Three stage, waveform

- 7.1. Output pulse - Angle-Time Duration (turn-on/turn-off)

- 7.2. Output pulse - Angle-Time Duration (turn-on/no-action)

- 7.3. Output pulse - Angle-Angle Duration (turn-off/toggle)

- 7.4. Output pulse - Angle-Angle Duration (turn-on/turn-off)

- 7.5. Output data updated during an event, end modification allowed

- 7.6. Output data updated during an event, end modification not allowed

- 7.7. Output event with overlap between two events

- 7.8. Output event starting within minimum off time

- 7.9. Multiple injection pulses

- 7.10. Injection constraints

- 7.11. Main injection event

- 7.12. Injector pulse duration is composed of dead time and flow time

- 7.13. Clipped injection event

- 7.14. Injection events in 360° mode

- 7.15. Post injection events

- 7.16. Knock window schedule

- 7.17. Knock signal processing for the HIP901x family of processors

- 7.18. Spark event relative to cylinder's TDC-firing angle

- 7.19. Spark event relative to cylinder's TDC-firing angle

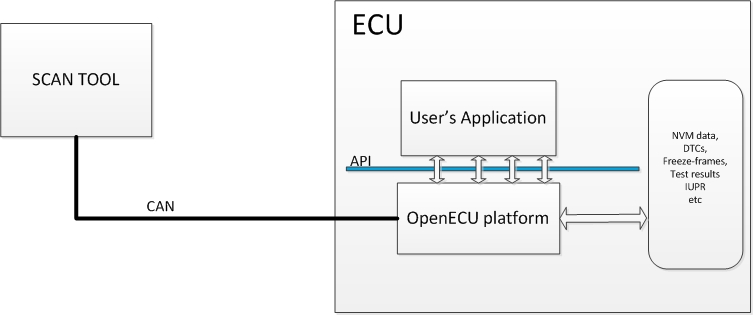

- 8.1. Functional Levels within a Diagnostics System

- 8.2. Scan tool link via platform

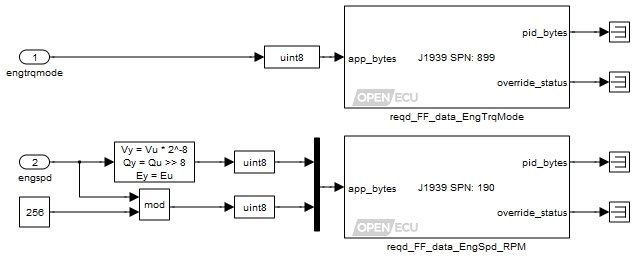

- 8.3. Use of PID blocks to collect data

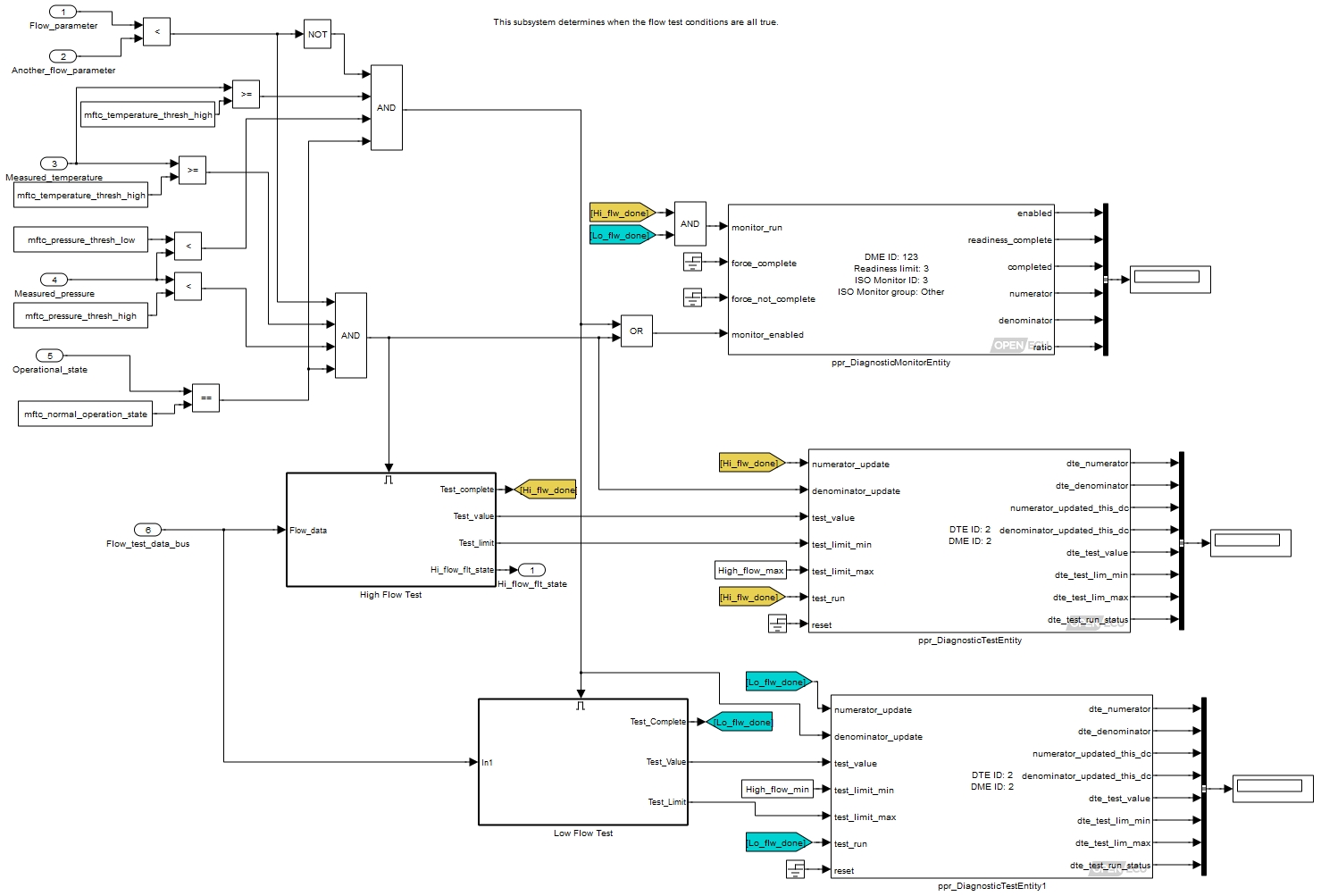

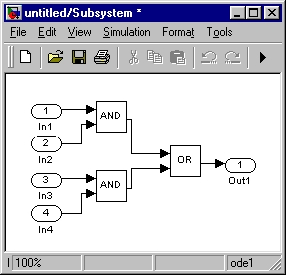

- 8.4. Building a diagnostic system — monitor level

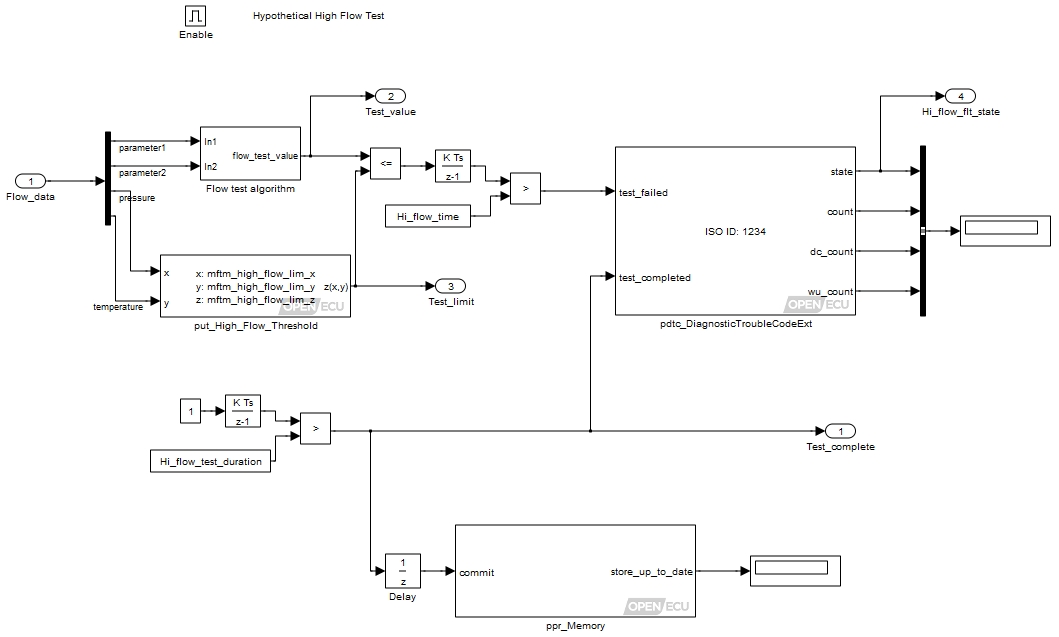

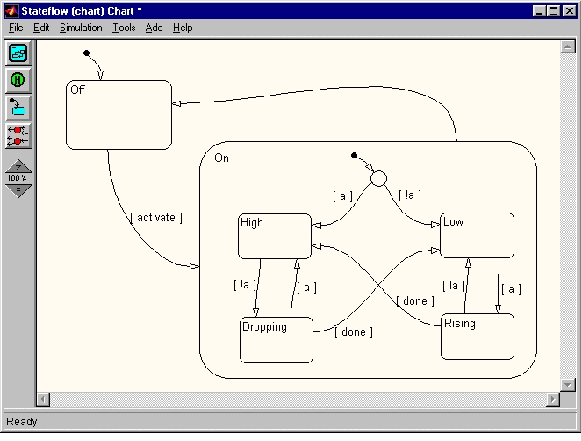

- 8.5. Building a diagnostic system — individual test

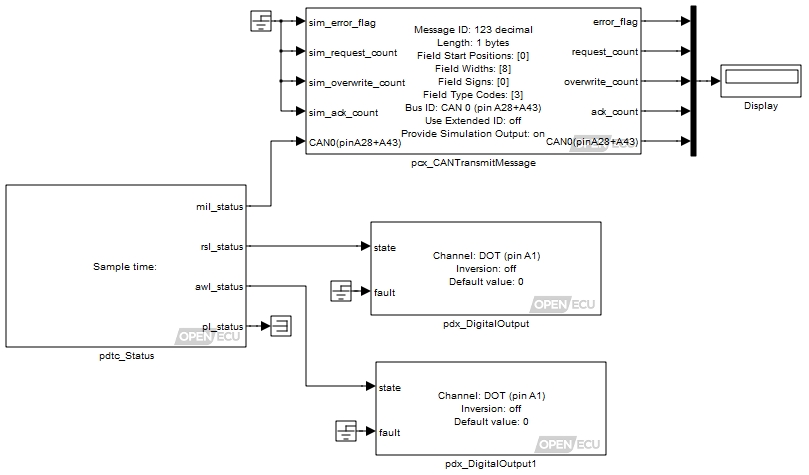

- 8.6. Building a diagnostic system — warning lamps

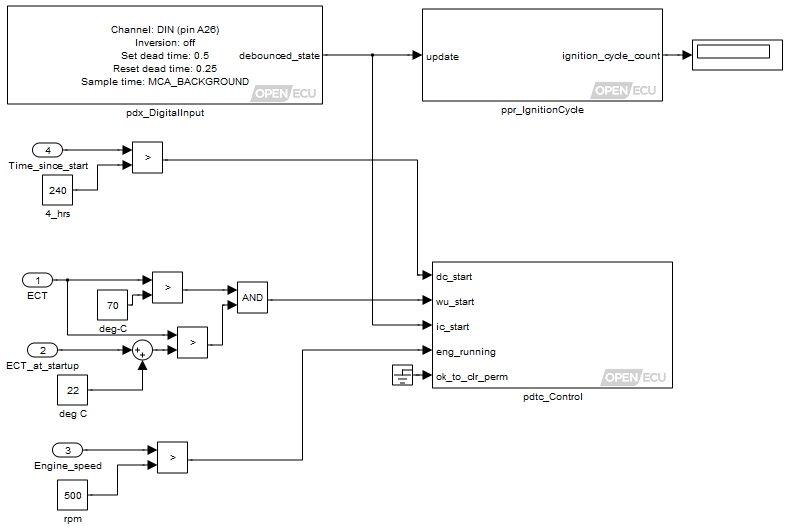

- 8.7. Building a diagnostic system — generic counters

- 8.8. J1939 request/response example

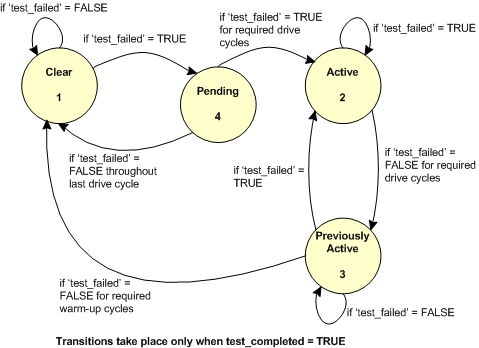

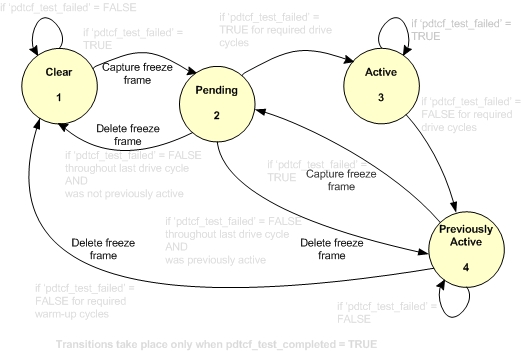

- 8.9. Platform OBD state machine - no transitions between Previously Active and Pending

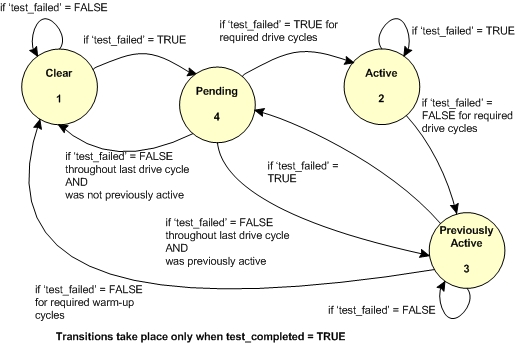

- 8.10. Platform OBD state machine - transitions between Previously Active and Pending

- 8.11. Freeze frame capture and deletion

List of Tables

- 2.1. Third party tool compatibility

- 2.2. Install components

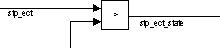

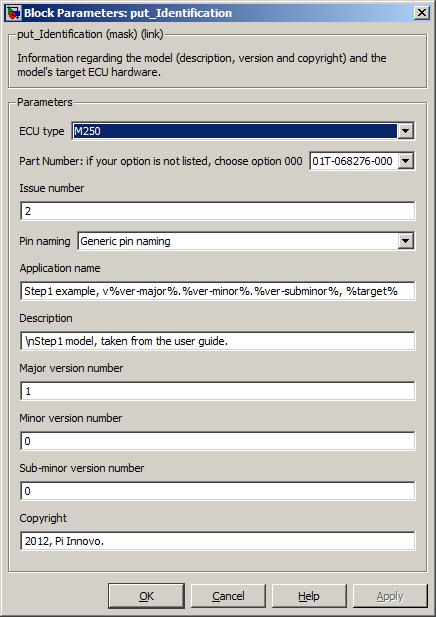

- 3.1. Step1 - model identification block parameters

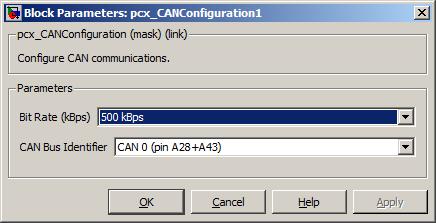

- 3.2. Step1 - CAN configuration block parameters

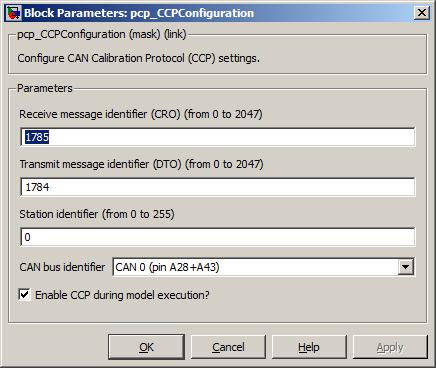

- 3.3. Step1 - CCP configuration block parameters

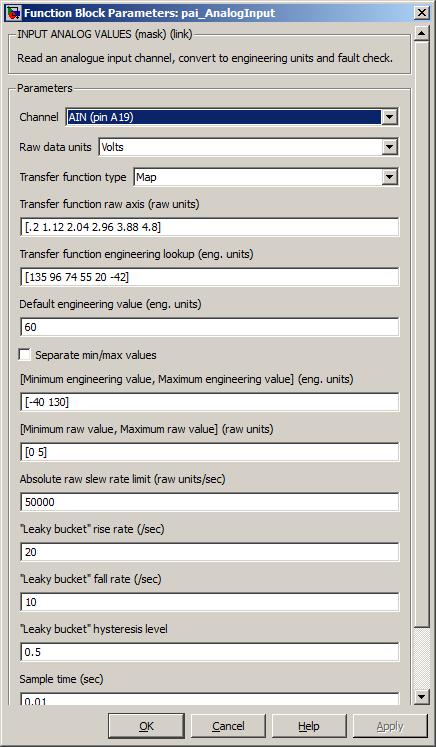

- 3.4. Step1 - analogue input block parameters

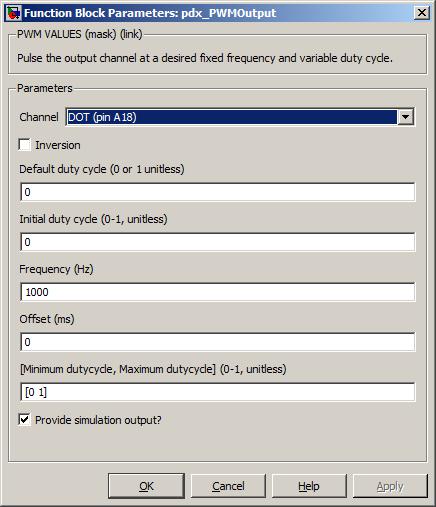

- 3.5. Step1 - PWM output block parameters

- 3.6. Simulink model colouring

- 3.7. FEPS voltages

- 4.1. Standard MATLAB commands

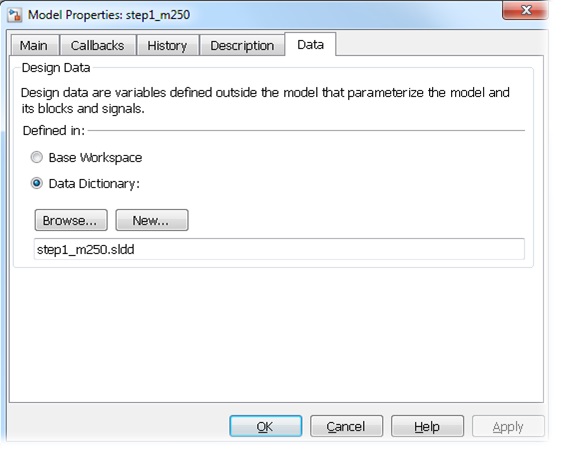

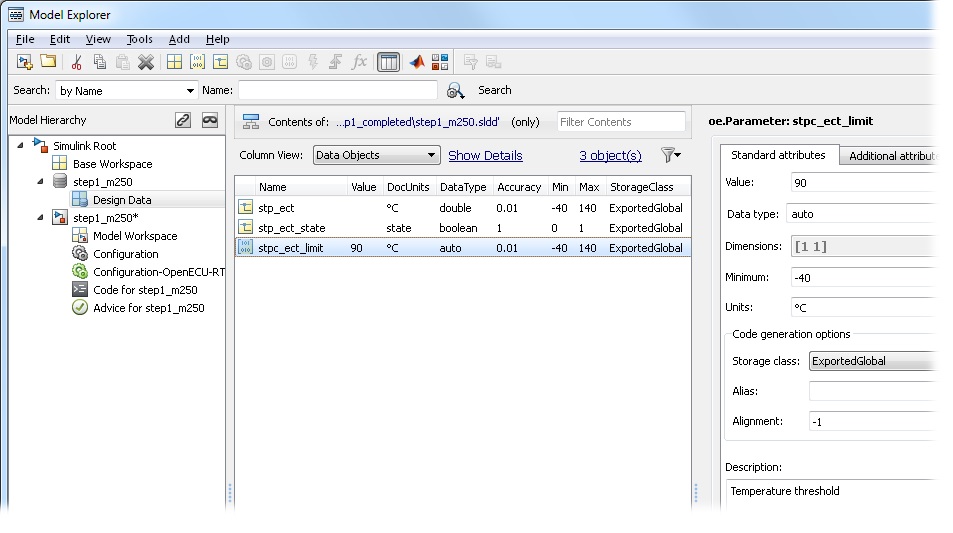

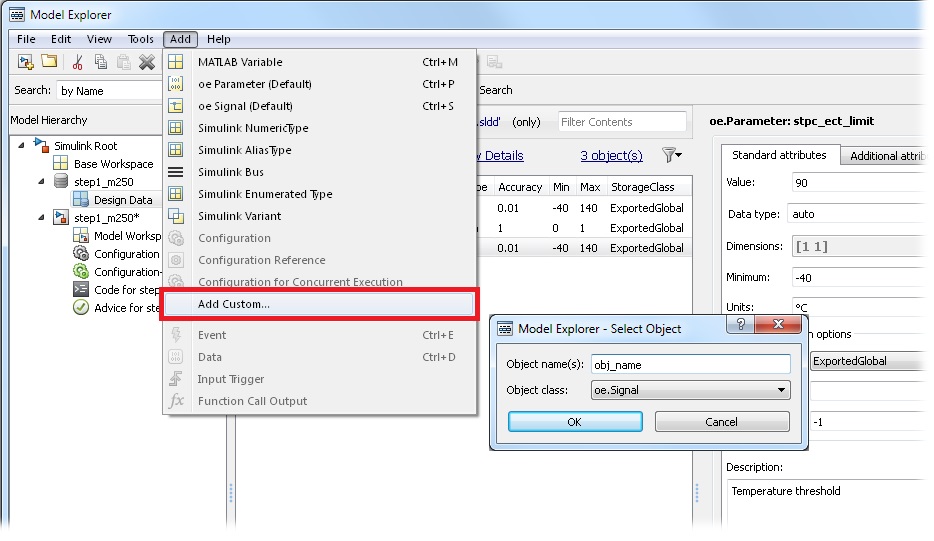

- 4.2. Data dictionary columns

- 4.3. Simulink data dictionary object properties

- 4.4. Simulink data dictionary object storage classes

- 4.5. FEPS voltages

- 4.6. ASAP2 naming schemes

- 4.7. FEPS voltages

- 4.8. Library and application tasks

- 4.9. Model simulation settings for R2015a

- 4.10. Model simulation settings for R2015b

- 4.11. Model simulation settings for R2016a

- 4.12. Model simulation settings for R2016b

- 4.13. Model simulation settings for R2017a

- 4.14. Model simulation settings for R2017b

- 4.15. Model simulation settings for R2018a and R2018b

- 4.16. Model simulation settings for R2019a, R2019b, and R2020a

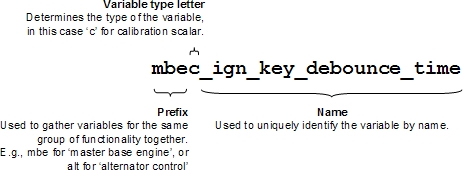

- 5.1. Variable naming convention

- 5.2. 1-d map lookup naming convention

- 5.3. 2-d map lookup naming convention

- 6.1. Interval notation

- 6.2. CAN block type codes

- 6.3. CCP defaults

- 6.4. Generic pin naming convention

- 6.5. Supported Key/Value pairs

- 6.6. CAN signal gap error codes

- 6.7. CAN signal prepare invalid codes.

- 6.8. CAN signal validate error codes.

- 6.9. Automatic ASAP2 entries for boot build information

- 6.10. Automatic ASAP2 entries for reprogramming build information (M220, M221, M250, M460, M461, M670)

- 6.11. Automatic ASAP2 entries for platform build information

- 6.12. Automatic ASAP2 entries for application build information

- 6.13. Automatic ASAP2 entries for application rate task timing information

- 6.14. Automatic ASAP2 entries for auxiliary task timing information

- 6.15. Automatic ASAP2 entries for CPU loading information

- 6.16. Automatic ASAP2 entries for eTPU loading information

- 6.17. Automatic ASAP2 entries for maximum application rate task timing information

- 6.18. Automatic ASAP2 entries for run-time information

- 6.19. Automatic ASAP2 entries for reset information (M110, M220, M250, M460, M461)

- 6.20. Automatic ASAP2 entries for number of instances of period overruns of periodic tasks

- 6.21. Automatic ASAP2 entries for memory use information

- 6.22. Automatic ASAP2 entries for memory error correction events

- 6.23. Automatic ASAP2 entries for floating point conditions

- 6.24. Automatic ASAP2 entries for J1939 related information

- 6.25. Software component versions (for M110-000)

- 6.26. Software component versions (for M220-000)

- 6.27. Software component versions (for M220-0AU)

- 6.28. Software component versions (for M221-000)

- 6.29. Software component versions (for M250-000)

- 6.30. Software component versions (for M460-000)

- 6.31. Software component versions (for M461-000)

- 6.32. Software component versions (for M670-000)

- 7.1. Function availability based on engine synchronisation mode

- 7.2. Crankshaft signal decoding error bitmap values

- 7.3. Angular digital output pin actions

- 7.4. Function availability based on engine synchronisation mode

- 7.5. Function availability based on engine synchronisation mode

- 8.1. Diagnostic Service Comparisons

- 8.2. PDG supported services

- 8.3. DTC initialisation values

- 8.4. RoutineControl request sub-function

- 8.5. InputOutputControl Status (KW2000-3 draft)

- D.1. Memory configurations supported

- D.2. Memory configurations supported

- D.3. Memory configurations supported

- F.1. Supported CCP commands

- F.2. Supported CCP commands (in older versions of ECUs)

- F.3. Original EXCHANGE_ID message

- F.4. Modified EXCHANGE_ID message

- F.5. EXCHANGE_ID selection values

- F.6. EXCHANGE_ID manufacturing data key values and binary format

- I.1. Release summary for v2.9.0-r2020-1

Before using OpenECU, it is very important to read and understand the warning and safety information given in Section 1.7, “Warnings and safety guidelines” and in Section 1.8, “Warning”.

Pi, the Pi logo and OpenECU are trademarks of Pi Innovo Ltd. Microsoft, Windows, Excel, Word, MATLAB, Simulink, StateFlow, Vision, CANape and INCA are all registered trademarks of their respective owners.

Pi Innovo makes no representation or warranties of any kind whatsoever with respect to the contents hereof, and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose. Pi Innovo shall not be liable for any errors contained herein, or for incidental or consequential damages in connection with the furnishing, performance or use of the software, associated hardware, or this written material.

Pi Innovo reserves the right to revise this publication from time to time, and to make changes in the content hereof without obligation to notify any person of such revision or changes.

A copy of the Pi Innovo Terms and Conditions of Sale is available on request, and includes a declaration of the warranty and limitation of liability which apply to all Pi Innovo products and services.

Under the terms of European and UK Health and Safety Legislation, Pi Innovo is required to classify any hazardous materials in the products it supplies and to provide relevant safety information to users.

Any hazardous materials in Pi products are clearly marked with appropriate symbols. Product Safety Data Sheets relating to these materials are available on request.

Thank you for choosing Pi Innovo's OpenECU platform.

Pi Innovo's OpenECU platform offers a new solution to engine and vehicle control system development. Based on Pi's extensive experience of ECU development, and backed by Pi's unrivalled capabilities in project and customer support, OpenECU helps you get quickly to what you need: working, robust control systems.

By using production ECU hardware as an auto-code platform, you gain all the advantages of auto-coding and rapid prototyping, but with hardware that meets full production environmental and packaging requirements (see Section A.1, “ECU hardware reference documentation” for environmental and packaging details).

The OpenECU system consists of:

a range of production ECU hardware modules for engines with up to 8 cylinders (or more with multiple modules);

an optional range of tested engine and vehicle control strategies, from individual functional blocks to complete strategy suites;

a comprehensive range of support and consultancy services, ranging from sensor selection and system design advice through to complete bespoke system development.

Applications of the OpenECU platform include:

engine control system development;

chassis control system development;

transmission control system development;

hybrid powertrain control system development;

vehicle fleet trials.

For support contact information, please see the last page of this manual.

Simulink is a powerful simulation and analysis software engine which is used throughout academia and industry to develop and analyse dynamic systems.

Simulink is a widely used software package for modelling, simulating and analysing dynamic systems, which is based upon the MATLAB software engine. It allows you to build graphical models of linear and non-linear systems, using a simple drag-and-drop interface and a library of functional blocks. You can then simulate your model under dynamic running conditions to analyse its behaviour, and continuously interact with the parameters while the simulation is running.

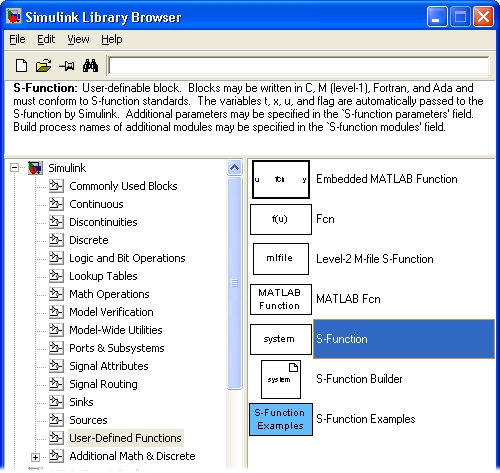

Many functional blocks are included in the standard Simulink library, allowing you to model any system whose dynamics you want to simulate. This library is supplemented by Pi's OpenECU blocks, which are specialised for use with the OpenECU platform.

There are several OpenECU packages available from Pi, which can include the following items.

The following items of hardware are available as part of OpenECU:

- Electronic Control Unit (ECU)

This is the computer that monitors and controls all aspects of the electronic system's behaviour. Code generated from your Simulink model is programmed into the ECU. There are four different models of ECU currently available — 4 in-line cylinder and V8 cylinder, in both development and fleet models (see Section A.1, “ECU hardware reference documentation” for further details).

- Connectors

All the connectors and terminals required to connect the ECU, the calibration tool and your PC together.

- Tools

You will require a crimping tool for the ECU connectors. Pi Innovo will give you details on request.

The following items of software are available as part of OpenECU:

- Complete OpenECU strategy suites (optional)

These are complete Simulink models that simulate all the control functionality of an entire engine or other dynamic system. Complete strategies comprise many levels of design and modelling, and are the product of many years of design research and testing at Pi Innovo. Complete strategies are available for petrol (I4 and V8 cylinder) systems.

- OpenECU Simulink strategies (optional)

These are complete Simulink models that have been designed to simulate whole blocks of engine control functionality, such as spark generation, rev limiting, etc. They are the blocks from which the complete strategy suites (above) are developed. Designed by Pi, they can be integrated with your own models, and are used in exactly the same way as all Simulink blocks.

- OpenECU Simulink blocks

These functional blocks supplement those that are normally available in Simulink, and are used to create inputs, outputs and signal processing capabilities for engine-related functions such as angle calculations, spark timings, etc. They are designed by Pi, and form the platform for higher-level engine functionality, but are used in exactly the same way as all Simulink blocks. They are the blocks from which the strategies (above) are developed.

And the following items of software are required but not provided as part of OpenECU.

- Calibration Tool

This electronic tool is used to program the auto-generated code into the ECU, and to monitor (and, in some cases, alter) the values of certain parameters while the ECU is running. Pi's own PiSnoop product is one option, along with several industry-standard alternatives, and we will be able to recommend a suitable product on request.

- Compiler

A tool which takes the Simulink generated code representing the graphical model and turns it into an executable image that can be run on OpenECU hardware.

OpenECU allows for several different options enabling different features. The licensing system retains control of the ability to use these features depending on what the customer has purchased.

The current set of available features is:

OPENECU

The main feature. Enabled when you purchase any version of OpenECU

CAPI_BUILD

Allows for building OpenECU applications with the C-API. This feature is also a prerequisite for SIMULINK_BUILD.

SIMULINK_SIMULATE

Allows for simulation of OpenECU models in Simulink. This feature is also a prerequisite for SIMULINK_BUILD.

SIMULINK_BUILD

Allows for building OpenECU models with the Sim-API. Because the Sim-API wraps the C-API, both features are required to build OpenECU Simulink models

EXT_DIAG

Extended diagnostics features.

- Allows use of the Extended diagnostics blockset in Simulink models.

- Allows use of the Extended diagnostics library functions at run time in OpenECU applications

To make the best use of OpenECU, certain hardware, software and knowledge requirements need to be fulfilled, as described below.

To run the Pi OpenECU software with MATLAB and Simulink, you will need an IBM-compatible PC with the minimum specifications listed below. These specifications are the same as those for running MATLAB:

CPU: a modern Intel or AMD x86 32-bit or 64-bit processor.

RAM: 2 GiB minimum, but more recommended (larger models will require more RAM).

Free hard disk space: 2 GiB.

Peripheral hardware: keyboard, mouse, DVD/CD-ROM drive (for installation from CD media), at least 8-bit graphics adapter and display (for at least 256 colours).

Either the physical system or a system simulator, is ultimately required to test and calibrate your ECU and the system model you have created to run on it. A suitable Calibration/reprogramming communications tool is also required conforming to the ASAP2 standard.

You will need the following software pre-installed on your PC:

Operating system: Microsoft Windows 10 or Microsoft Windows7 SP1 32-bit or 64-bit.

MathWorks: MATLAB and Simulink (and optionally, Stateflow and Stateflow Coder):

See OpenECU Compatibility with Third Party Tools for a complete list of supported versions.

MathWorks: Simulink Coder (formerly Real-Time Workshop) versions:

See OpenECU Compatibility with Third Party Tools for a complete list of supported versions.

Wind River Diab compiler; version 5.5.1.0 (M220, M221, M250, M460 and M461); or version 5.8.0.0 (M220, M221, M250, M460 and M461); or version 5.9.0.0 (M220, M221, M250, M460, M461 and M670). Only the C language version is required (note, C++ is not yet supported).

Calibration tool: PiSnoop, ATI Vision™ (version 2.5 through 5.1.2), ETAS INCA (version 7.2.7) or Vector CANape (version 8.0 through 16.0).

Note

OpenECU developer software does not support earlier versions of Windows than XP (SP3), Windows Vista, or Windows 8.

See the Chapter 2, Installation for full details of the software required.

This manual describes how to incorporate the OpenECU Simulink blocks provided by Pi Innovo into your own designs, but does not include a MATLAB or Simulink guide or tutorial. Please refer to the user guides that accompany that software for full installation and operating instructions.

A working knowledge of design modelling and system dynamics principles in an engineering environment is required to make the best use of Simulink and OpenECU. Ultimately, it is the quality of your own system designs that will be reflected in the quality of your system control strategy.

Note also that there are serious hardware and personal safety considerations involved in developing automotive control systems. Please make sure that you read and understand the Safety and Warning section at the end of this chapter to reduce the chance of any such hazards.

The OpenECU design and build process is comprised of the following steps:

Design a model of your system, using Simulink library blocks, and optionally those blocks that Pi Innovo has developed and included for the OpenECU platform. If you have purchased a complete engine strategy suite, this will have been done for you. This process will typically have many cycles of design and HIL (hardware-in-loop) testing.

Once you are satisfied that your model simulation functions within your design parameters, the C code can be auto-generated from Simulink.

The C code is passed to the compiler, which generates the executable for the ECU operating system. This is then programmed into the ECU using the Calibration Tool.

The ECU is then connected to either the physical system or a system simulator (e.g. Pi AutoSim). There then follows a cycle of calibration and testing to optimise the model and its parameters to the particular characteristics of the target system (or simulator). This may involve returning to the Simulink model to adapt its design.

Pi Innovo has over 14 years of experience designing powertrain controllers, working closely with customers to get to the best possible control system solution. Millions of cars and trucks on the road use Pi-designed engine control.

OpenECU comes with a wide range of options for customer and project support, allowing you to draw on over 500 man-years of control system design experience. Whichever option you choose, you can count on real commitment from Pi to provide what you need, and to go the extra mile.

For contact information, refer to Appendix K, Contact information.

It is very important to read and understand the following warnings and safety guidelines. Inappropriate use of the OpenECU system can lead to loss of data, damage to software and hardware, and possible personal injury if safe vehicle operation is compromised.

The safe operation of OpenECU is the responsibility of the those using it. The level of risk associated with the user's application must be ascertained and appropriate mitigation devices used to reduce the potential risks to an acceptable level. These mitigation devices may include a system 'kill switch', driver training, backup systems and use of the vehicle in safe environments.

A structured approach to testing is recommended, particularly before the product is used in environments where it may be in contact with members of the public (e.g. the public highway). This testing may include HIL, static vehicle system test and/or vehicle test in a test track environment.

Pi Innovo supplies OpenECU on the basis that:

The responsibility for ensuring that the use of OpenECU is safe lies with the customer.

The customer will include appropriate mitigation devices as identified by the hazard analysis they perform (such as engine kill switch, back up devices).

The user will read all OpenECU documentation (including this document) to ensure its safe use.

OpenECU is not to be used in safety critical applications, e.g. aerospace.

OpenECU is to be used in a system development environment only.

OpenECU is not to be sold to the public.

All users must be competent to make appropriate safety judgements.

Pi Innovo also strongly recommends that:

Applications be developed using a process suitable for the application.

HIL testing be used prior vehicle testing.

"Off public highway" vehicle testing be performed prior to road testing.

Pi Innovo considers the safety and quality of its products to be of paramount importance. The integrity of the product can be considered by assessing the three 'components' which comprise the system.

Systems, rather than software, have a Safety Integrity Level (SIL). The SIL of the customer's resultant system will have to be assessed and defined by their knowledge of the processes used to develop all the components (including those supplied by Pi) comprising the complete system.

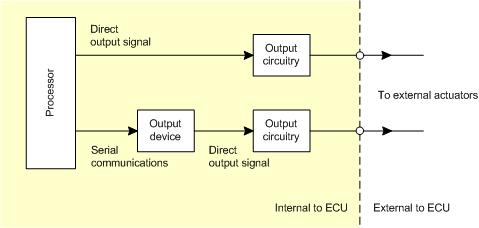

The hardware is a production unit (see Section A.1, “ECU hardware reference documentation” for module environmental specifications). However different applications will have different requirements for output monitoring. Those outputs that are selected (by the customer) to drive safety related outputs should include output monitor circuits. The use of outputs for critical devices which do not contain a monitor feedback is strongly discouraged.

The platform comprises functionality which allows the high level strategy to operate in the specific hardware target (electronic box). It includes:

This suite of software is predominantly hand-coded with some additional auto-coded Simulink models.

OpenECU has been developed using a lean SIL0 process enabling its rapid introduction to the market place. This process included internal review, module testing and considerable vehicle testing. It is considered to be a reliable and robust platform on which to build vehicle control applications.

The configuration of the platform is the customer's responsibility. It is entirely possible, through careless configuration, to 'cross wire' inputs or outputs for example. This could, for example, lead to injector 1 firing when you intended injector 2 to fire. The mis-calibration of analogue inputs could lead to undesired behaviour such as steering angle or accelerator pedal position to be mis-calculated.

Documented vehicle prove out tests should mitigate against this leading to severe outcomes.

The strategy may be developed entirely by the customer, or be a development by the customer of generic libraries supplied by Pi Innovo. In either case the integrity of the resultant strategy model must be the responsibility of the customer.

Pi's generic libraries have been extensively validated via module testing, HIL system testing and vehicle testing but have not undergone unit testing.

The supplied libraries have been validated for a specific application and a specific hardware set. The user MUST validate the correct function of the strategies in their application.

The process of testing automotive systems can involve many personal safety hazards — high-speed machinery, extremely flammable and potentially explosive fuels, and the possibility of loss of vehicle control is a combination that can be fatal if sensible precautions are not followed.

As the system designer and tester, it is your responsibility to ensure that your working practices are specifically designed to minimise or eliminate the possibility of personal injury, and to incorporate into your designs such fail-safe functionality as is necessary. This includes the avoidance of certain dynamical situations such as open throttles and other 'positive feedback' scenarios where control of the system may be lost.

Pi Innovo makes no representation or warranties of any kind whatsoever with respect to the contents hereof, and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose. Pi Innovo shall not be liable for any errors contained herein, or for incidental or consequential damages in connection with the furnishing, performance or use of the software, associated hardware, or this written material.

Pi Innovo reserves the right to revise this publication from time to time, and to make changes in the content hereof without obligation to notify any person of such revision or changes.

A copy of the Pi Innovo Terms and Conditions of Sale is available on request, and includes a declaration of the warranty and limitation of liability which apply to all Pi Innovo products and services.

- 2.1. Introduction

- 2.2. Installing OpenECU

- 2.3. License setup

- 2.4. Removing OpenECU

- 2.5. Integration notes for third party tools

- 2.5.1. Microsoft Windows 10

- 2.5.2. Microsoft Windows 7

- 2.5.3. Microsoft Windows XP

- 2.5.4. MATLAB

- 2.5.5. PiSnoop

- 2.5.6. ATI Vision

- 2.5.7. ETAS INCA calibration tool

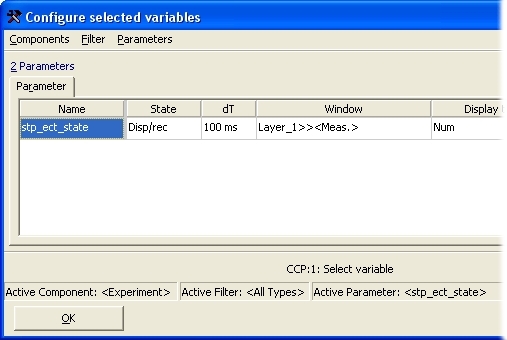

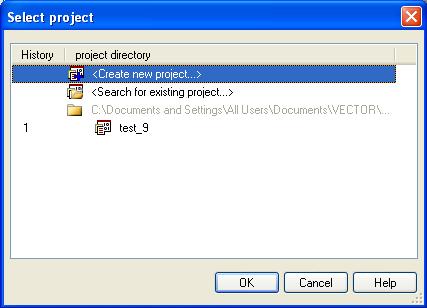

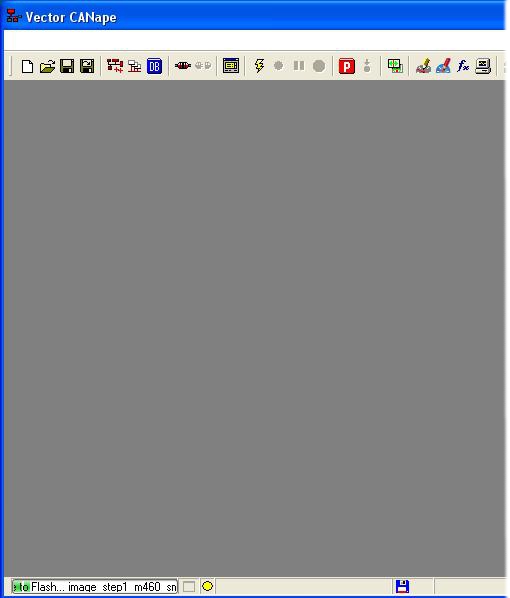

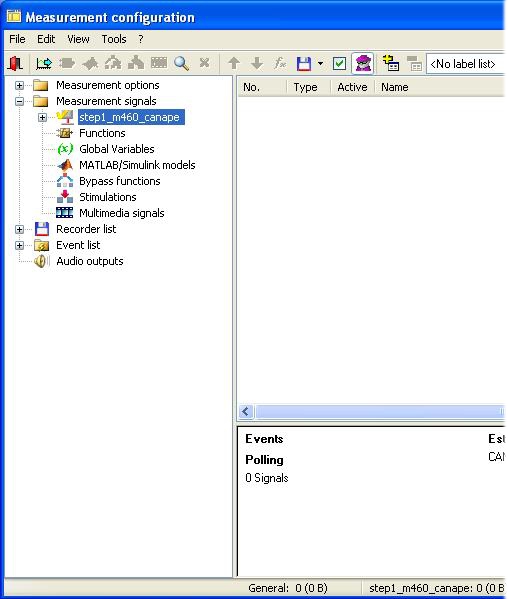

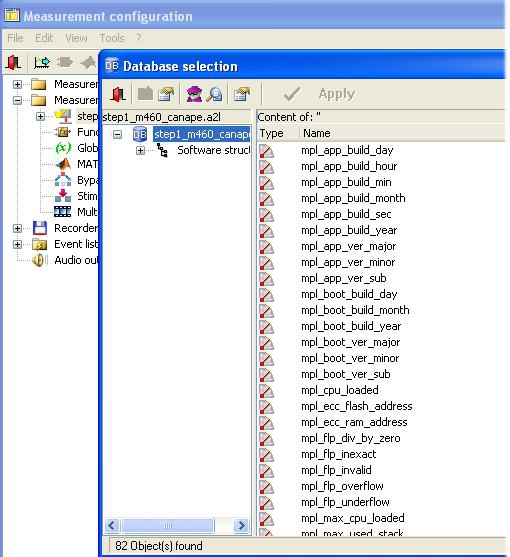

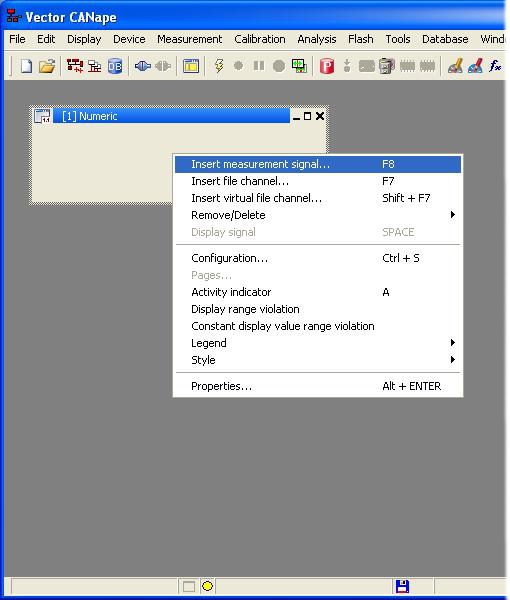

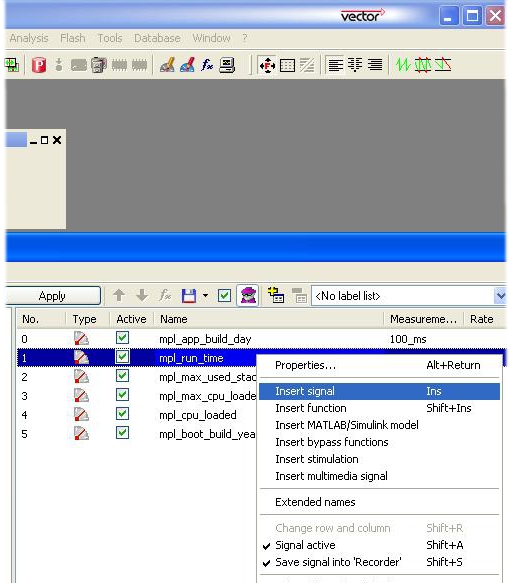

- 2.5.8. Vector CANape

- 2.5.9. Wind River (Diab) C Compiler v5.5.1.0

- 2.5.10. Wind River (Diab) C Compiler v5.8.0.0

- 2.5.11. Wind River (Diab) C Compiler v5.9.0.0

- 2.5.12. GCC Compiler v4.7.3

- 2.5.13. Python

This chapter describes the installation process for the OpenECU Simulink Blockset package and its dependencies.

OpenECU developer software has been tested to work with Windows 10. OpenECU is compatible with Windows 7 SP1 (32-bit and 64-bit) and Windows XP SP3, but support for these operating systems is deprecated. OpenECU is not compatible with Windows Vista or Windows 8.

For C based development, OpenECU requires (at a minimum) one of the following compiler tools:

Wind River Diab compiler

GCC Compiler

Note

GCC is an optional component in the OpenECU installation (installed by default). Additionally, GCC support is currently in a beta stage. As such, there a number of known limitations for compiling an OpenECU application with GCC. Please see the “Integration notes for third party tools” of the “Release notes” for a list of known issues building with GCC for further details.

To program and calibrate an OpenECU with an application, OpenECU integrates with the following calibration tools. Only one calibration tool is required:

PiSnoop

ATI VISION

ETAS INCA

Vector CANape

For Simulink model based development, OpenECU requires (at a minimum) the following MathWorks tools:

MATLAB (base product)

Simulink (to develop the models)

Simulink Coder (to generate C code from the models)

MATLAB Coder (Simulink Coder depends on this)

In addition, if you need to add state diagrams to the model, then you will also need:

Stateflow (to develop state flow diagrams inside your model) Simulink Coder generates C code from the state flow diagrams inside your model.

Simulink Coder generates C code which does not lend itself to efficient repeatable testing. When creating a production version of your product, you may need better control of the structure of the C code generated from the model to reduce the cost of testing the C code against any industry standards. Under these circumstances you will also need:

Embedded Coder (to generate C code from the models)

To compile the generated C code (from either Simulink Coder or Embedded Coder), you will need one of the following compilers:

Wind River Diab compiler

GCC compiler (free compiler but with known issues)

To program and calibrate an OpenECU with an application, OpenECU integrates with the following calibration tools. Only one calibration tool is required:

PiSnoop

ATI VISION

ETAS INCA

Vector CANape

OpenECU works with a number of applications (both required and optional) supplied by other companies. If you intend to use OpenECU with one of the following tools, it is best to install them before OpenECU. The installer will then integrate the OpenECU developer software with these applications.

MATLAB: (see OpenECU Compatibility with Third Party Tools for a list of supported versions)

ETAS INCA calibration tool (version 7.2.7)

OpenECU works with a number of other applications, but these need not be installed prior to the OpenECU developer software.

Simulink Coder, formerly Real-Time Workshop, (optional): (see OpenECU Compatibility with Third Party Tools for a list of supported versions)

Embedded Coder, formerly Real-Time Workshop Embedded Coder, (optional): (see OpenECU Compatibility with Third Party Tools for a list of supported versions)

Stateflow: (see OpenECU Compatibility with Third Party Tools for a list of supported versions)

Wind River (Diab) C compiler (versions 5.5.1.0, 5.8.0.0 and 5.9.0.0) for M110, M220, M221, M250, M460 and M461 targets

Wind River (Diab) C compiler (version 5.9.0.0) for M670 target

GCC Compiler (version 4.7.3 free compiler option) for M110, M220, M250, M460, M461 and M670 targets

Note

GCC is an optional component in the OpenECU installation (installed by default)

PiSnoop (any version)

ATI Vision calibration tool (version 2.5 through 4.0)

Vector CANape calibration tool (version 8.0 through 13.0)

The applications above have been listed with a version or release number. These are the versions or releases that OpenECU has been tested against. It may be that OpenECU will work with other versions of these applications, but it is recommended against and Pi may not provide technical support if these versions or releases are not used.

In summary, the following third party tools are compatible with this version of OpenECU:

Table 2.1. Third party tool compatibility

| Third party tool | Compatible versions |

|---|---|

| Operating systems | |

| Microsoft Windows [a] |

Win10 (64-bit)

Win7 SP1 (32-bit) (deprecated) Win7 SP1 (64-bit) (deprecated) XP SP3 (32-bit) (deprecated) |

| Modelling and code generation tools | |

| MathWorks MATLAB |

R2015a,

R2015b

(32-bit)

|

| MathWorks Simulink | |

| MathWorks MATLAB Coder | |

| MathWorks Simulink Coder [b] | |

| MathWorks Embedded Coder | |

| Compiler tools [c] | |

| Wind River Diab C compiler |

v5.5.1.0, v5.8.0.0, v5.9.0.0 for

M110,

M220,

M221,

M250,

M460 and

M461

targets

v5.9.0.0 for M670 target |

| GCC Compiler [d] | v4.7.3 for M110, M220, M250, M460, M461 and M670 targets |

| Reprogramming, data logging and calibration tools [e] | |

| PiSnoop | Any version |

| ATI Vision [f] [g] | v2.5 through v5.1.2 |

| ETAS INCA | v7.2.7 |

| Vector CANape | v8.0 through v16.0 |

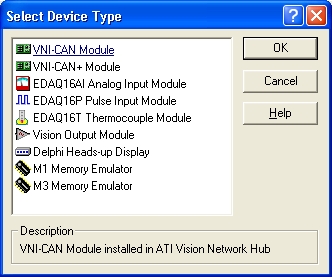

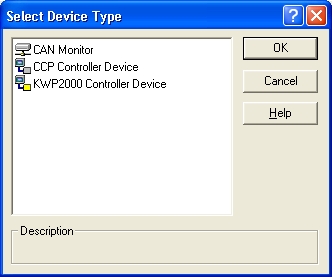

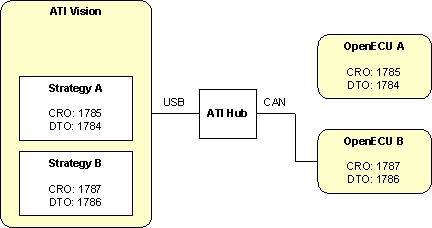

[a] OpenECU developer software has been tested to work with Windows 10. OpenECU is compatible with Windows 7 SP1 (32-bit and 64-bit) and Windows XP SP3, but support for these operating systems is deprecated. OpenECU is not compatible with Windows Vista or Windows 8. OpenECU developer software may not function correctly on encrypted drives. OpenECU developer software must be able to create files on the host file system. If using an encrypted drive, be sure that permission settings will allow OpenECU to create files. Pi Innovo cannot provide support for issues with encrypted drives. [b] Mathworks Simulink Coder includes functionality of RTW and Stateflow Coder. [c] All OpenECU targets use Freescale PowerPC microcontrollers. The M110, M220, M221, M250, M460 and M461 use an MPC5534 microcontroller, the M670 uses an MPC5674F microcontroller. The M560 and M580 use an MPC5746C for the primary microcontroller and SPC560P34 for the secondary microcontroller. See the Technicical Specification for your target for more information. [d] OpenECU has only been tested using GCC Compiler version 4.7.3 and is in the beta stage. As such, there are a number of known issues to keep in mind when compiling an OpenECU application using GCC. For further details, please see "Integration notes for third party tools" for a list of known issues. [e] These tools have been tested for reprogramming, data logging, and calibration. Some of them have many other features which have not been tested with OpenECU. [f] The OpenECU method of configuring ATI Vision uses standardised ASAP2 files. As a result, all future versions of Vision are expected to be backwardly compatible (e.g., version 3.7 and version 4.0 are known to be compatible). [g]

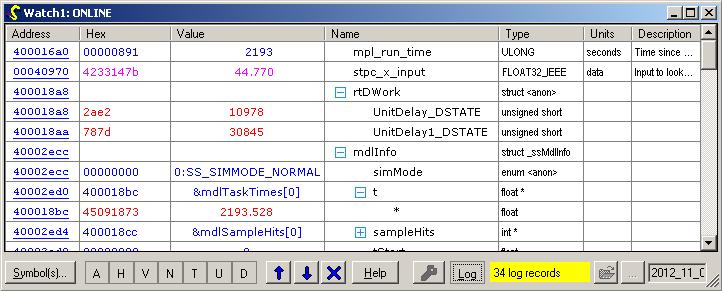

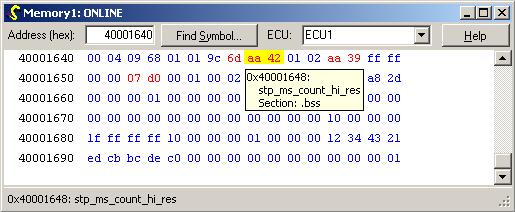

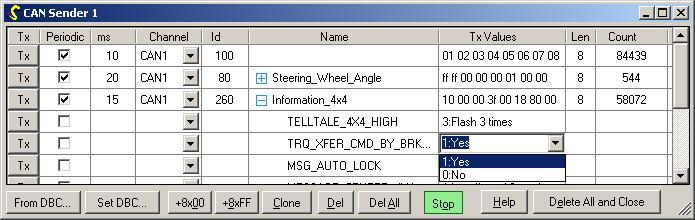

The following Vision toolkits are typically used when working

with OpenECU:

Data Acquisition Toolkit,

Calibration Toolkit,

Universal ECU Interface Standard Toolkit,

APOLLO Data Analysis Toolkit,

CAN Interface Toolkit and

HORIZON Scripting/Remote API Toolkit.

In particular, the HORIZON Scripting/Remote API Toolkit

is required if OpenECU builds are to generate Vision strategy files

( | |

Some third party tools have been marked deprecated and support for these tools will be removed in a future release of OpenECU.

| Third party tool | Replacement |

|---|---|

| MathWorks MATLAB R2015a | MATLAB latest version (see Pi Innovo's website for a complete list of supported versions of MATLAB). |

| MathWorks MATLAB R2015b | |

| MathWorks MATLAB R2016a | |

| MathWorks MATLAB R2016b | |

| MathWorks MATLAB R2017a | |

| MathWorks MATLAB R2017b | |

| WindRiver Diab 5.5.1.0 | WindRiver Diab 5.8.0 and 5.9.0 |

The installer program, openecu_platform_2_9_0_r2020-1.exe,

installs all the necessary files for the OpenECU platform. This file can be obtained from the

Pi Document and Download Center web page.

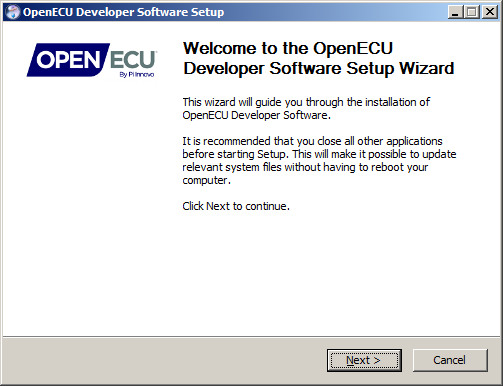

The installation process for the OpenECU developer software is performed by a wizard. To run the wizard, execute the appropriate installer program. The installation can be stopped at any point by selecting the Cancel button.

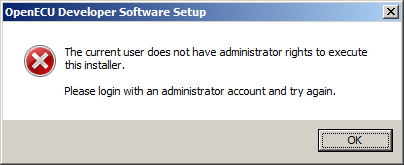

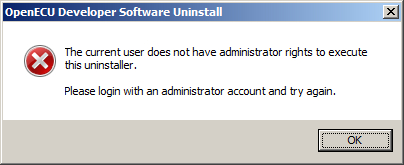

The installer requires that the user has administrative rights to make changes on the computer. If a user without rights is trying to execute the installer a dialog box will be displayed and the installation stops. Login with an administrator account or contact your network administrator and try again.

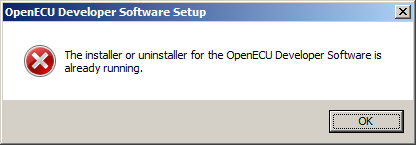

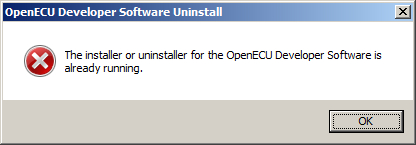

If a version of an OpenECU installer is already running, a dialog box will appear saying so. Select OK (which stops the current installer) and change to the other OpenECU installer to continue.

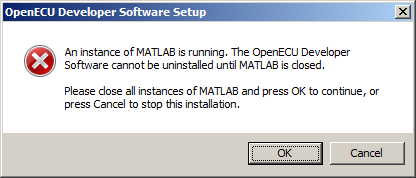

If a version of MATLAB is running, a dialog box will appear saying so. Quit all instances of MATLAB, then select OK to continue installation.

The installation process starts with an introduction. Select Next to continue.

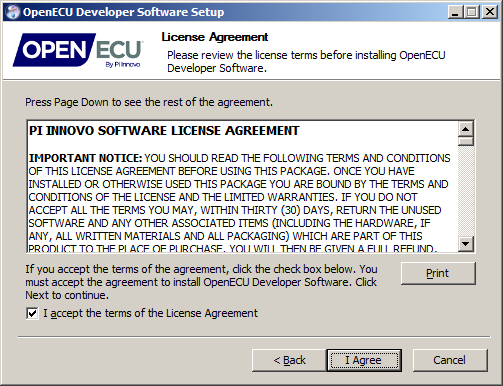

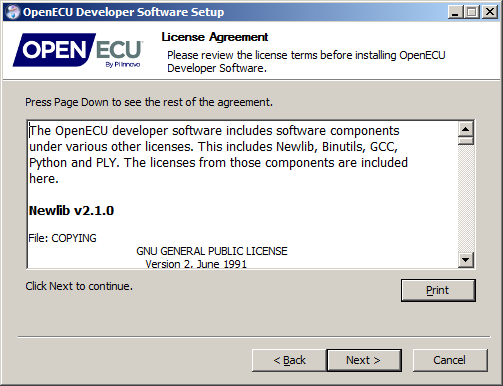

The next windows to appear present the license agreement for using OpenECU developer software and related software. Read the license agreements and if acceptable, select I accept the terms of the License Agreement and then Next. If not acceptable, do not install the software.

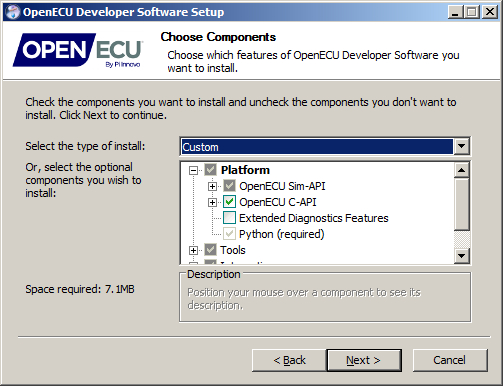

The next window to appear provides a number of components that can be installed or patched.

The following table breaks out each of the components:

Table 2.2. Install components

| Component | Required | Installed by default | Description |

|---|---|---|---|

| Platform | Yes | Yes | A selection of packages to install, including the C-API and Sim-API components. |

| OpenECU Sim-API | Yes | Yes | Install the Simulink interface to OpenECU, documentation and support packages. |

| Blockset | Yes | Yes | Install the OpenECU blockset. |

| Sim-API Manuals (HTML) | (optional) | Yes | Install the OpenECU blockset, ECU Technical Specifications and other documentation in HTML format. |

| Sim-API Manuals (PDF) | (optional) | Yes | Install the OpenECU blockset, ECU Technical Specifications and other documentation in PDF format. |

| Sim-API Examples | (optional) | Yes | Install some examples of how to use the OpenECU blockset. |

| OpenECU C-API | Yes | Yes | Install the OpenECU C-API files and libraries. |

| C-API | Yes | Yes | Install the C interface to OpenECU, documentation and support packages. |

| C-API Manuals (HTML) | (optional) | Yes | Install the OpenECU C-API User Guide, ECU Technical Specifications and other documentation in HTML format. |

| C-API Manuals (PDF) | (optional) | Yes | Install the OpenECU C-API User Guide, ECU Technical Specifications and other documentation in PDF format. |

| C-API Examples | (optional) | Yes | Install some examples of how to use the OpenECU C interface. |

| Extended Diagnostics Features | (optional) | No | Install the On-Board Diagnostic (OBD) library. This library is available at extra cost. |

| Python | Yes | Yes | Install the Python application. This application is used to provide build support when generating and compiling the model source code. |

| Tools | (optional) | No | Installs additional OpenECU tools. |

| GCC | (optional) | Yes | Installs the GNU Compiler Collection (v4.7.3) and related tools for OpenECU targets. |

| lmadmin installer | (optional) | No | Installs the installers for the lmadmin license server from flexera. |

| FreeCCP | (optional) | No | Installs the FreeCCP programming tool (note that this tool is provided without support or warranty). |

| Integration | (optional) | Yes | Options to have the OpenECU installer integrate OpenECU with third party tools, like MATLAB and INCA. |

| MATLAB Integration | (optional) | Yes | During installation, the OpenECU blockset is integrated into MATLAB's PATH. |

| INCA-ProF Integration | (optional) | No | During installation, INCA-ProF is update to understand how to program an OpenECU. |

| Start Menu Shortcuts | (optional) | Yes | During installation, the Window's Start menu is updated to include shortcuts to installed components. |

Adjust the component selection as required (especially if you require the installer to update an installed copy of ETAS INCA) and select the Next button.

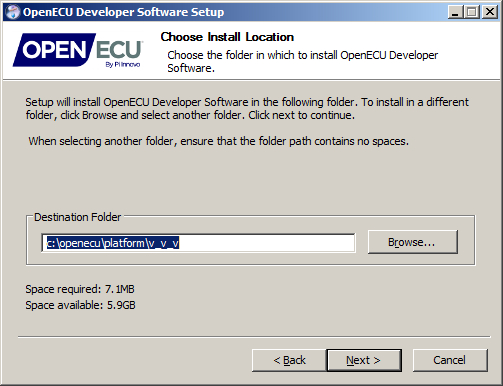

The next window asks for a destination path to be specified. By default, the installer presents a path to your local drive.

Warning

If the default path is changed, ensure that only digits, upper and lower case letters

and the _ character are used to specify directory names. An installation

path that includes any space characters will cause problems later on.

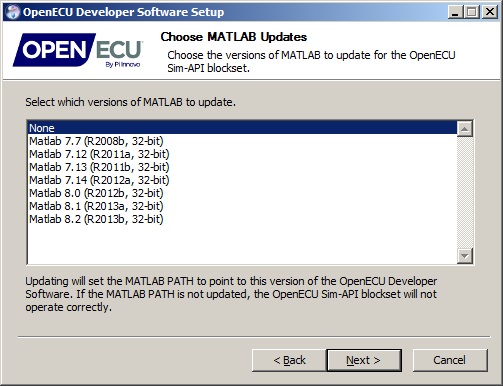

If the MATLAB integration component was selected, the next window presented provides a list of installed and compatible versions of MATLAB. The example here shows that OpenECU should be integrated with MATLAB R2008b.

Select which versions of MATLAB will be used with OpenECU and select the Next button. If no version should be updated select None.

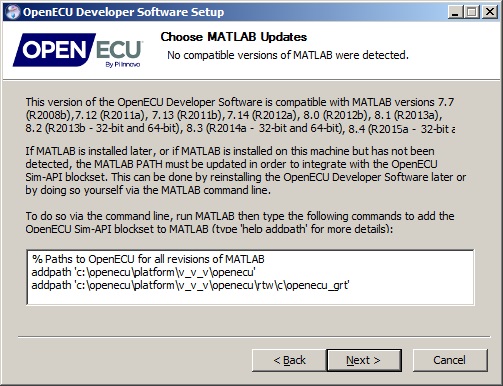

If no compatible versions of MATLAB were found, the next window presents the command to run to add OpenECU to MATLAB (more details given in Section 2.5.4, “MATLAB”).

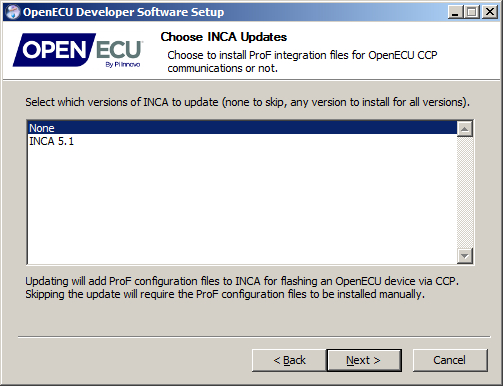

If the INCA-ProF integration component was selected, the next window presented provides a list of installed versions of INCA.

Select which versions of INCA will be used with OpenECU and select the Next button. If no version should be updated select None.

Note

If any version of INCA is selected, then the installer will add OpenECU integration to all versions of INCA. This is simply a consequence of the way INCA works.

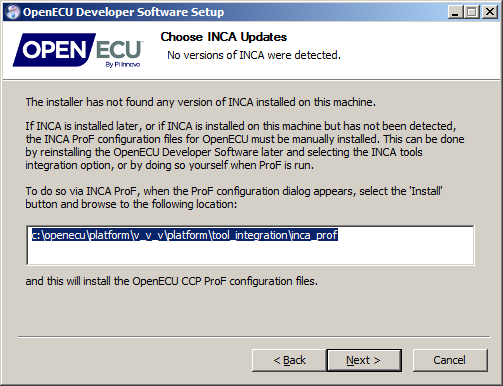

If no versions of INCA were found, the next window presents details on how to achieve this by hand (more details given in Section 2.5.7, “ETAS INCA calibration tool”). The instructions should be carried out when INCA-ProF runs.

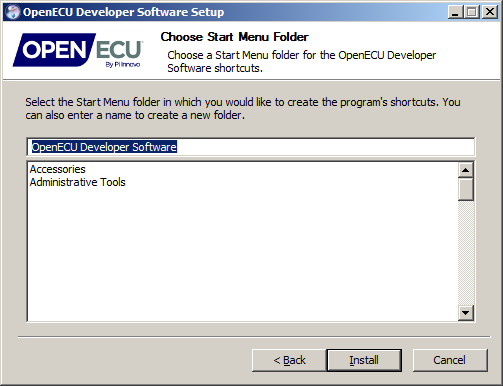

If the Start Menu Shortcuts component was selected, then the next window presented asks the user to select where in the Start menu the OpenECU items will be added. During install, the installer adds short cuts to the documentation components selected and to the OpenECU uninstall application.

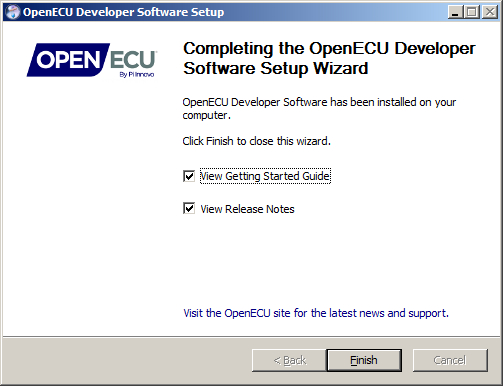

Once installation has completed, the user is provided an option to read the getting started guide, the release notes and to visit the OpenECU web site.

Getting started guide

If you are a first time user of OpenECU, it is strongly recommend following the getting started guide, which covers what tools can be used with OpenECU and how to configure OpenECU and those tools to work together.

Release notes

If you are installing a new version of OpenECU, it is strongly recommended that you read the release notes. Some releases of OpenECU change the functionality of features which may have an impact on existing applications.

Machine identification generated by the license tools is required to activate an OpenECU platform license.

This section is a quick setup guide to get OpenECU working with your license. Consult the license administration guide for more information on license management and administration. This document is provided with the installation at "[install path]\doc_user\License-Administration-Guide.pdf".

To setup a floating license, the vender daemon will have to be run on the designated license server as well as have a license file on that machine. This section describes setting up the vendor daemon for a floating license.

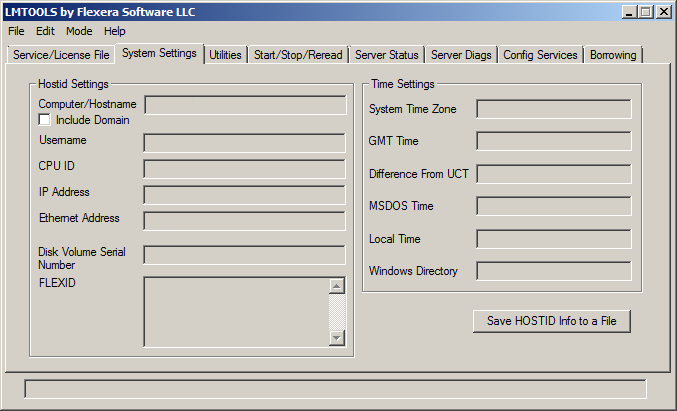

After installing the platform, copy the files in "[install path]\tools\flexera\i86_n3\" to your designated license server. On that machine, run lmtools.exe.

Select the "System Settings tab", check "Include Domain", and press the button that says "Save HOSTID Info to a File".

Email the file to Pi Innovo with the purchase order. When the purchase is complete, Pi will send you a valid license file. (Or if you have already completed the purchase, reply to the welcome email with this information)

It is recommended that lmadmin license server manager be used to serve licenses. Run the lmadmin installer to install the software. Once the installation is complete, copy the vender daemon, openecu.exe, into the install directory, "C:\Program Files (x86)\FlexNet Publisher License Server Manager\".

Start the license server manager. You can then use the web interface to upload the license file and start serving your license.

Note

If a license has not yet been purchased, email the file to Pi Innovo with the purchase order. When the purchase is complete, Pi will send a valid license file. If the purchace has already been completed, reply to the welcome email with this information.

It is recommended that lmadmin license server manager be used to serve licenses. Run the lmadmin installer and start the license server manager. The web interface can then be used to upload the license file and start serving your license.

Note

Details on installing and using the lmadmin tool are in Chapter 9 of the License Administration Guide, "[install path]\doc_user\License-Administration-Guide.pdf".

Note

lmgrd is also provided with the platform as an alternative to lmadmin; consult Chapter 10 of the License Administration guide for details on its use.

To setup a node-locked license, a license file must be placed on the development machine.

After installing the platform, run the file: '[install path]\tools\flexera\i86_n3\lmtools.exe'

Select the "System Settings tab", check "Include Domain", and Press the button that says "Save HOSTID Info to a File" (see screen shot above)

Email the file to Pi Innovo with the purchase order. When the purchase is complete, Pi will send you a valid license file. (Or if you have already completed the purchase, reply to the welcome email with this information) If a license has not yet been purchased, email the file to Pi Innovo with the purchase order. When the purchase is complete, Pi will send a valid license file. If the purchace has already been completed, reply to the welcome email with this information.

Copy the file to the directory "C:\openecu" or update the OPENECU_LICENSE_FILE environment variable with the location of your file.

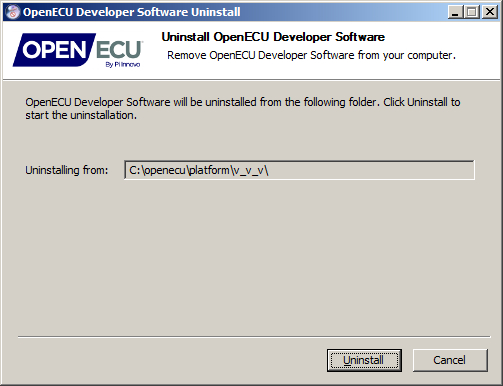

Navigate through the Windows All Programs Start Menu shortcuts and find the OpenECU Developer Software directory. Select the version of OpenECU to remove and run the uninstaller.

The uninstaller requires that the user has administrative rights to make changes on the computer. If a user without rights is trying to execute the uninstaller a dialog box will be displayed and the uninstaller stops. Login with an administrator account or contact your network administrator and try again.

If a version of an OpenECU uninstaller is already running, a dialog box will appear saying so. Select OK and change to the other OpenECU uninstaller to continue.

The uninstaller presents the location of the previous install to remove. Select the Uninstall button to continue (this will remove that version of OpenECU) or select the Cancel button to stop the uninstall.

When uninstalling, if this version of OpenECU is present in MATLAB's

PATH, then the uninstaller will not remove the reference.

Next time MATLAB is started, it will try to gain access to the

deleted OpenECU directory and will raise an error. When this occurs, manually remove

the OpenECU directories by selecting MATLAB's menu option File->Set Path....

Note

The OpenECU uninstaller does not remove the INCA-ProF configuration files for CCP.

The installer integrates the OpenECU package with Windows 10 by modifying the Start menu, by modifying some registry items and by copying files to a local drive.

OpenECU developer software may not function correctly on encrypted drives. OpenECU developer software must be able to create files on the host file system. If using an encrypted drive, be sure that permission settings will allow OpenECU to create files. Pi Innovo cannot provide support for issues with encrypted drives.

The installer integrates the OpenECU package with Windows 7 SP1 by modifying the Start menu, by modifying some registry items and by copying files to a local drive.

OpenECU developer software may not function correctly on encrypted drives. OpenECU developer software must be able to create files on the host file system. If using an encrypted drive, be sure that permission settings will allow OpenECU to create files. Pi Innovo cannot provide support for issues with encrypted drives.

The installer integrates the OpenECU package with Windows XP SP3 by modifying the Start menu, by modifying some registry items and by copying files to a local drive.

OpenECU developer software may not function correctly on encrypted drives. OpenECU developer software must be able to create files on the host file system. If using an encrypted drive, be sure that permission settings will allow OpenECU to create files. Pi Innovo cannot provide support for issues with encrypted drives.

The installer integrates the OpenECU package with MATLAB and Simulink. However, if for any reason the installer could not find an installed version of MATLAB, the user can manually integrate the OpenECU blockset by issuing the following MATLAB commands:

addpath '[install path]\openecu'

addpath '[install path]\openecu\rtw\c\openecu_ert\code_templates'

addpath '[install path]\openecu\rtw\c\openecu_ert'

addpath '[install path]\openecu\rtw\c\openecu_grt'

addpath '[install path]\openecu\rtw\c\openecu_grt_rsim'

addpath '[install path]\openecu\mex_r<release>'

addpath '[install path]\openecu\mfile'

addpath '[install path]\openecu\model'

Note

where the text [install path] is replaced by the installed

location of the OpenECU blockset, e.g., c:\openecu\platform\1_9_2;

and the text <release> is replaced with the major

version of MATLAB (e.g., 2013b or 2013b_64

for 64-bit versions of MATLAB).

Once the path has been added, the user can check the OpenECU version by issuing the following MATLAB command:

ver openecu

A correct response will look something like:

OpenECU Blockset (Pi Innovo) Version <number> <date>

If nothing is printed, or an error message is returned, then the path specified by

the addpath command was incorrect and should be changed.

Open: When loading an OpenECU model, Simulink may issue warnings similar to this:

Warning: Model '...' was last saved using an old version (...) of Simulink. For advice on upgrading this model to the current version of Simulink, see the Upgrade Advisor. > In oe_test_required_platform_vers at 26 In oe_make_rtw_hook at 153 In openecu_make_rtw_hook at 6 In general\private\openmdl at 13 In open at 159 In uiopen at 167

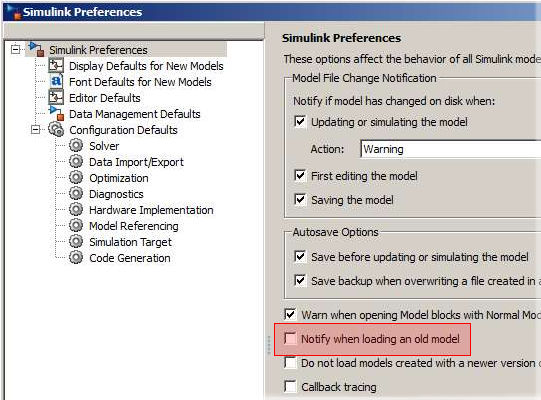

Workaround: Turn off the Notify when loading an old model option in Simulink's preferences:

Unlike some other calibration tools, during installation there is nothing special to be done when integrating PiSnoop and OpenECU.

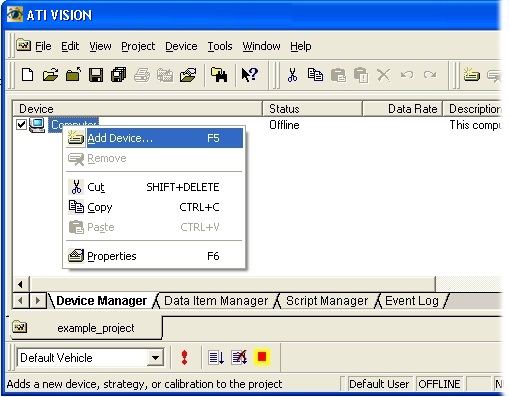

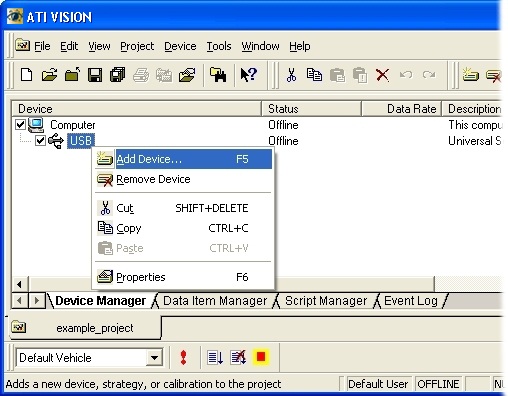

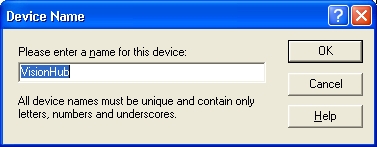

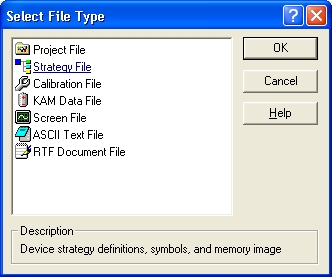

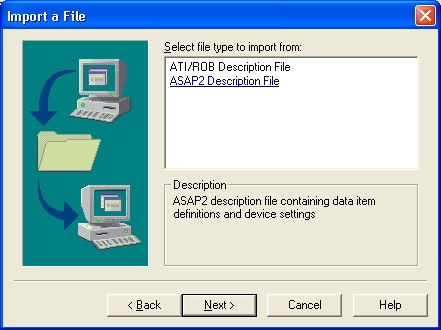

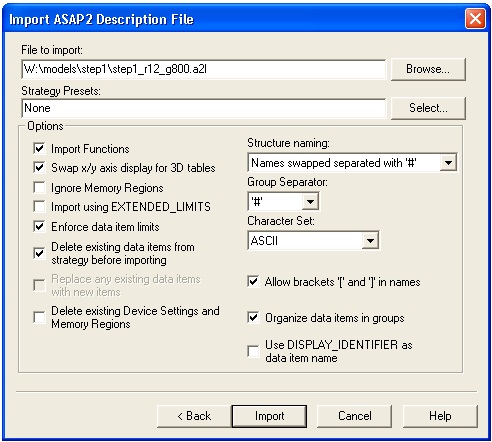

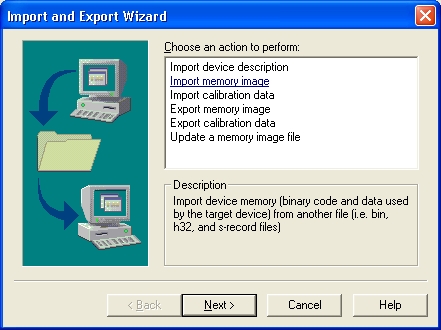

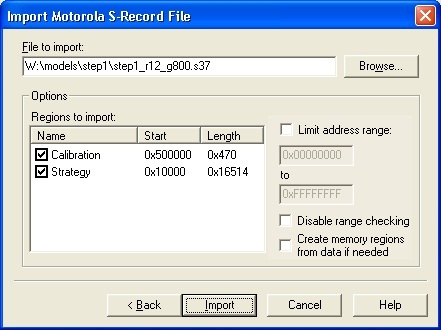

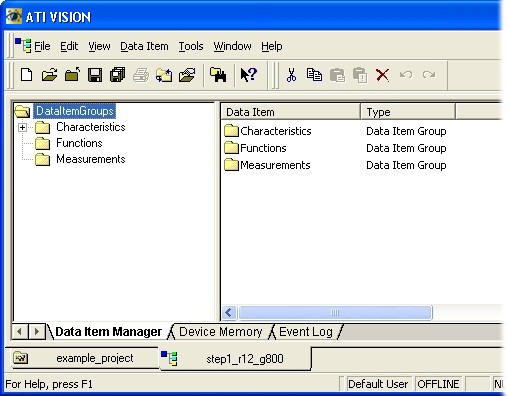

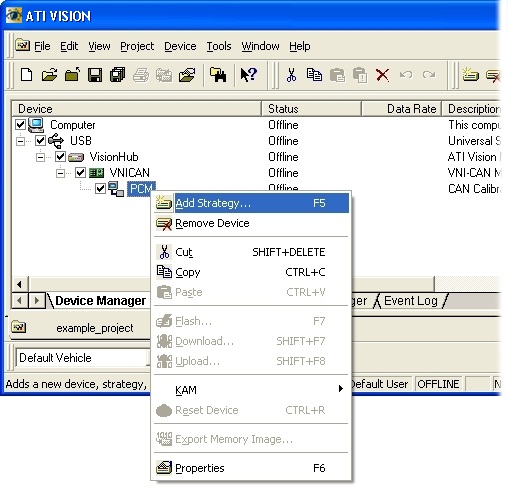

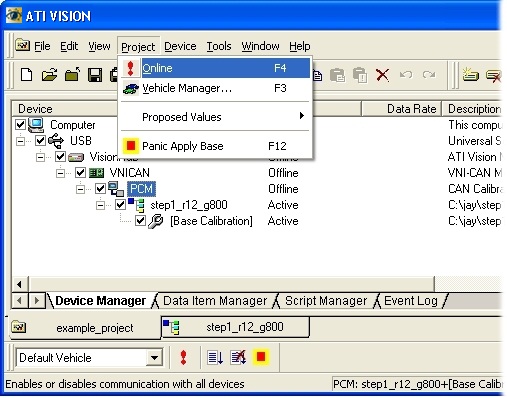

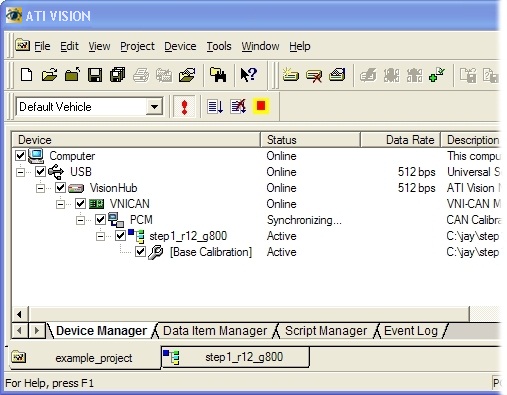

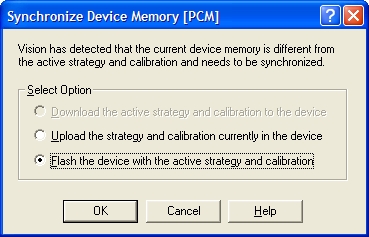

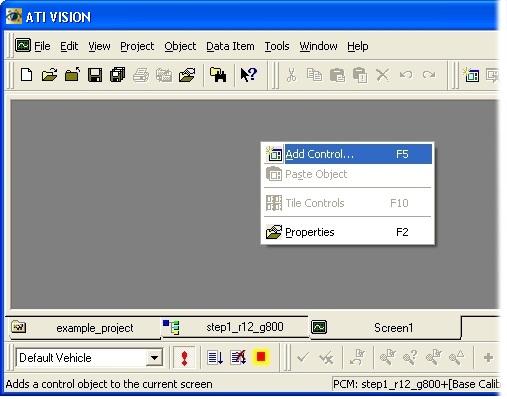

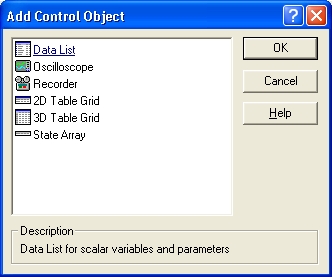

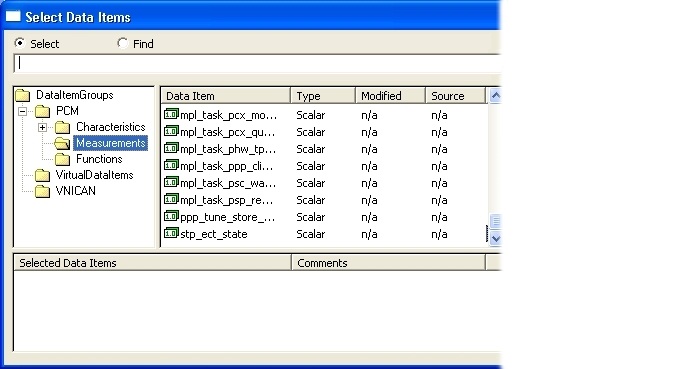

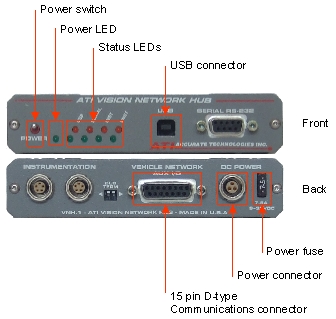

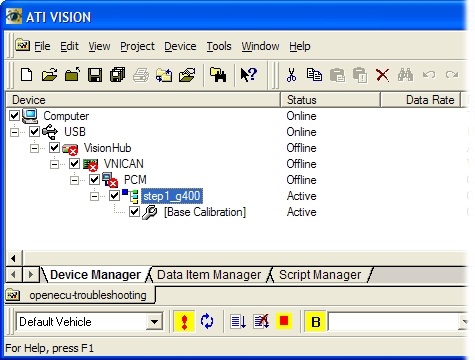

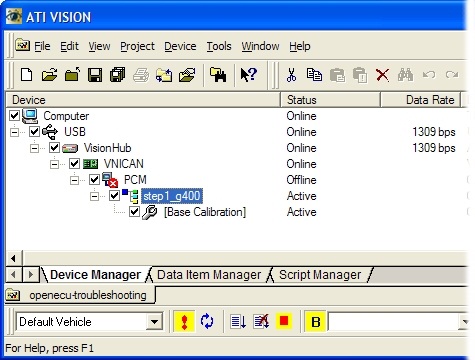

Unlike some other calibration tools, during installation there is nothing special to be done when integrating Vision and OpenECU.

Open: integration issues with OpenECU while creating a Vision VST (strategy) file.

There have been integration issues between Vision and OpenECU, when the user requests a build create a Vision VST (strategy) file. If OpenECU cannot create a strategy file, then it may be necessary to register the COM interface for Vision by running the

RegisterCOMInterface.batfile included in the install of ATI Vision.Open: does not operate correctly with encrypted hard drives.

There have been reports of Vision interacting poorly with encrypted hard drives. At the moment, it is not clear what the problem might be. On one occasion, Pi worked with ATI and a customer and determined a work around that is not understood. The work around was to rename the executable file for Vision to something longer than 11 characters.

Open: some earlier versions do not support CCP seed/key correctly.

ATI Vision 2006 (v3.2) is the earliest version for which CCP seed/key security has been validated by Pi Innovo. Earlier versions may support CCP seed/key security (see the relevant Vision documentation) but bugs in the CCP implementation on various targets are known to exist. ATI have recommended that earlier versions should not be used, or should be used with caution.

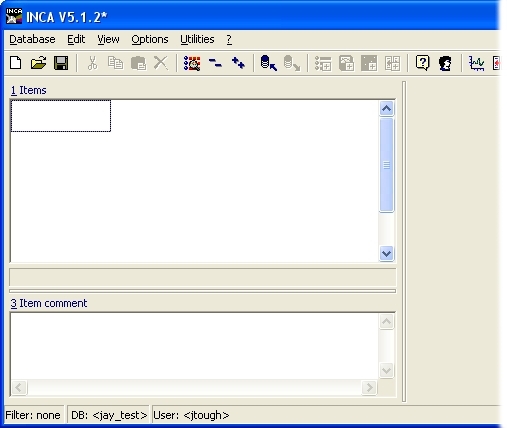

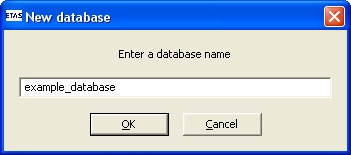

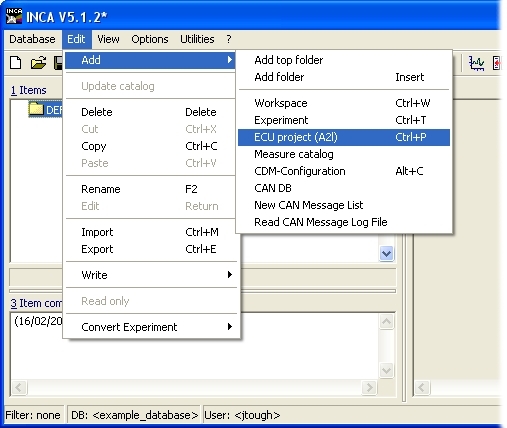

The installer integrates the OpenECU package with the ETAS INCA tool. However, if for any reason the installer could not find an installed version of INCA, the user can manually integrate the necessary ProF component.

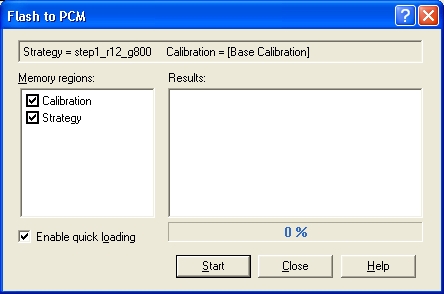

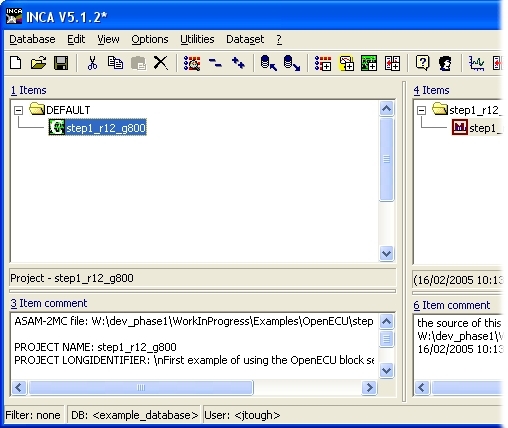

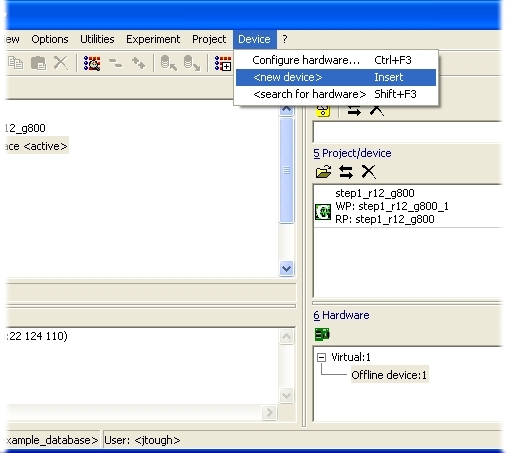

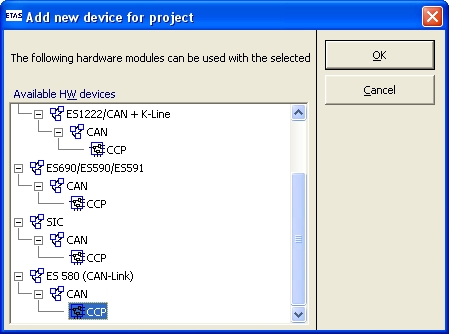

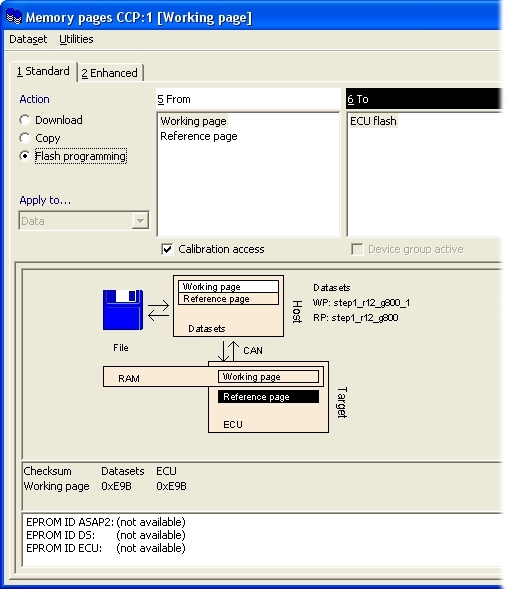

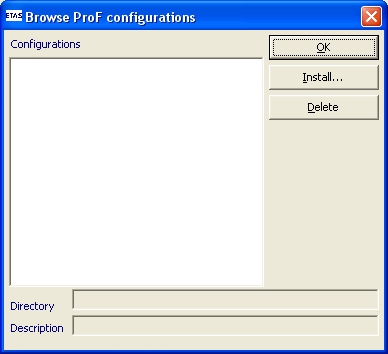

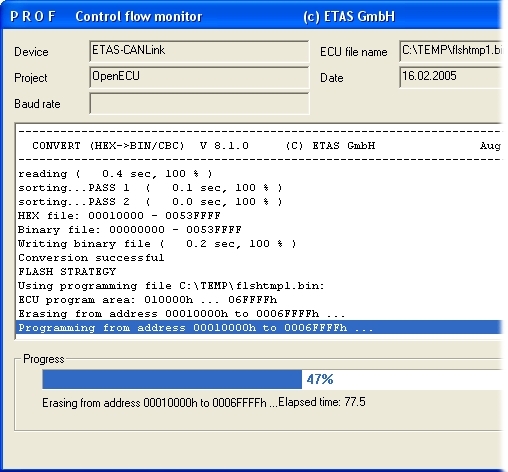

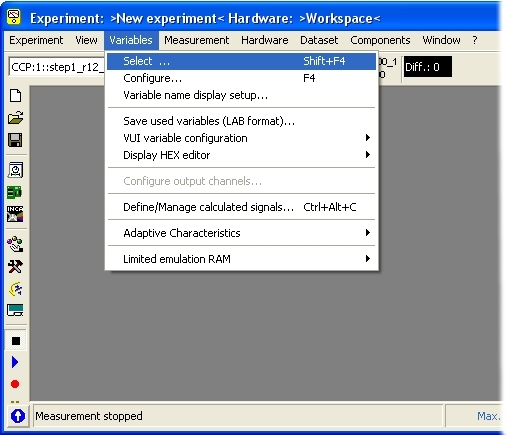

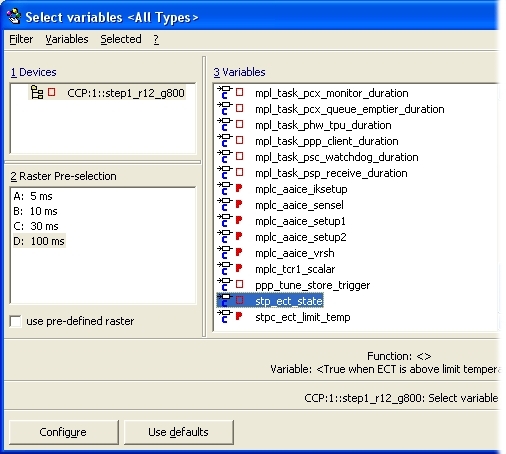

The INCA-ProF tool programs OpenECU over CCP using a set of configuration files. In order to manually integrate these configuration files, the user must run INCA, open an experiment, select manage memory then flash programming.

The user is then presented with a dialog box to browse ProF configurations, or a ProF settings dialog box (in which case the user must select Configure...).

With the browse ProF configurations dialog box, select the "Install..." button and browse to the install location of OpenECU:

[install path]\tools_integration\inca_prof

and select OK. This will have manually installed the INCA-ProF configuration file for OpenECU.

Note

If manually integrating and the ProF files cannot be found in the location above, then re-run the OpenECU installer and select the Integration -> INCA-ProF Integration option and try again.

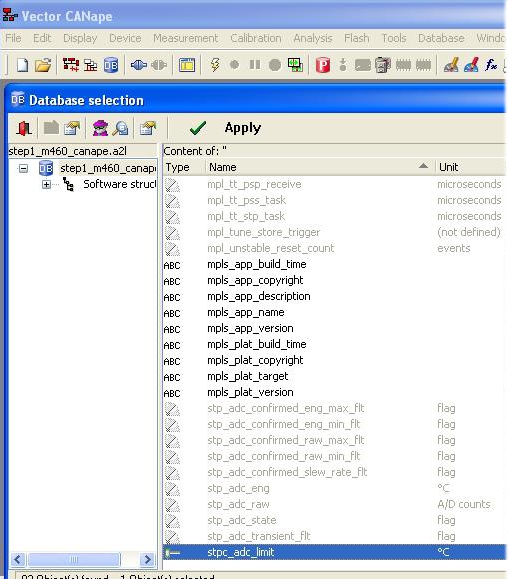

Unlike some other calibration tools, during installation there is nothing special to be done when integrating CANape and OpenECU.

The Wind River (Diab) compiler 5.5.1.0 can be installed by running the file

setup.exe from the supplied media — several

options will be presented during the compiler install and the following

responses should be used:

On Choose your Activation Type window, select one of the following options:

Permanent activation if you have been assigned with a license file from Wind River, usually named

WRSLicence.lic. The full path should point to the license file.Temporary activation if you wish to use the Wind River (Diab) compiler on an evaluation basis, or temporary basis until a permanent license is provided.

A reboot may be required to complete installation of the Wind River (Diab) compiler.

If using one version of the Wind River (Diab) compiler, either setup the

OPENECU_DIAB_5_5_1_0environment variable as described in the next point, or adjust Window's system path to include the absolute path to the compiler'sbindirectory.If using more than one version of the Wind River (Diab) compiler (for instance, when you are using two or more versions of OpenECU which require different versions of the Wind River (Diab) compiler), the environment variable

OPENECU_DIAB_5_5_1_0must be set to the absolute path to the compiler'sbindirectory. This macro must terminate in a “\” and must use the DOS 8.3 short naming convention.E.g.,

D:\Progra~1\diab\5_5_1_0\win32\bin\Note

After setting the environment variable, MATLAB may need to be restarted to pick up the new setting. If in doubt, issue the:

oe_check_compiler

command at MATLAB's prompt to check that the environment variable is correctly setup and the compiler is available.

Closed: incorrect generation of object code for “float <= float” comparisons.

The compiler incorrectly generates object code for “float <= float” comparisons, turning the comparison into “float > float”. This issue has been resolved by removing the

-Xieee754-pedanticcommand line option to the compiler command line option to the build configuration files.

Open: incorrect generation of object code for long C functions.

The compiler incorrectly generates jump instructions in the object code if the jump destination address differs from the address of the jump instruction by more than 15 bits (signed). No warning or error is generated by the compiler. The result is a model which does not behave as expected when run on target (usually the ECU appears as if it is continually resetting).

To alert the user to this risk, an OpenECU build checks for large functions and issues a warning message if any are found. The message takes the form:

Warning: Function foo is very large (0x000abcdef). The generated object code may be susceptible to a known compiler defect. Refer to the OpenECU user guide for further details.

Workaround (Simulink): RTW generates just a couple of C functions for the model, rather than splitting major sub-systems into their own functions. Hence those functions can become large enough to hit this compiler problem if the model is large. This can be avoided by applying the atomic subsystem option to key subsystems in the model. RTW generates a different C function for each atomic subsystem, where each resulting function corresponds to just part of what would have been one large function. You should split any large model up like this to avoid any one C function becoming large enough to hit this compiler problem.

Open: generation of non-existent labels.

The compiler can generate non-existent labels such as ".L1013" when compiling code involving large structures, such as those generated by TargetLink. The code then fails to link because the labels are not defined. This has not yet been seen with Simulink builds but it may possibly be seen in future.

Workaround: if this problem is encountered, a patched version of the compiler is available from Wind River for customers who have compiler support (quote service request 1054126).

Open: incorrect rounding on conversion from float to integer types.

The compiler rounds values when converting from floating point to integer, e.g. from "float" to "signed long" (in terms of native types, otherwise known as F32 and S32 in the OpenECU environment). For example, 3.6 as a float is rounded to 4 as an integer, but the C standard requires that the fractional part is truncated, so a converted value of 3 would be correct. Similarly -3.6 is rounded to -4 instead of being truncated to -3. This defect is fixed in version 5.8.0.0 of the compiler.

Workaround: if this problem is encountered, a patched version of the compiler is available from Wind River for customers who have compiler support (quote service request 864470).

Closed: Can't use Simulink look up blocks

There has been a known issue which restricts the compiler to use Simulink lookup block. When using Simulink lookup blocks, the Diab compiler would stop compilation with this error message:

'[model-name].c', line [line-num]: warning (dcc:1792): trying to assign 'ptr to volatile' to 'ptr'This has now been fixed, see F-CR 13325 in the release notes.

Closed: compiling the main model file can take a long time.

Small models compile in a short period of time, but once the code presented to the compiler exceeds a limit, the compiler takes a long time to compile the main model file (

model-name.c).Workaround: the compiler sets aside an amount of memory for the compilation phase and if the size of the model code exceeds the limit, the compilation slows down. This can be avoided by increasing the size of the compiler's buffer using a command line option. Add the

pcomp_CompileOptionsblock to the model, set the mode parameter toAdd to optionsand set the compiler options parameter to-Xparse-size=100000. If the compilation is still slow, increase the option value further.

The Wind River (Diab) compiler 5.8.0.0 can be installed by running the file

setup.exe from the supplied media — several

options will be presented during the compiler install and the following

responses should be used:

Follow the guidance given in Section 2.5.9, “Wind River (Diab) C Compiler v5.5.1.0”.

If using a single version of the Wind River (Diab) compiler, either setup the

OPENECU_DIAB_5_8environment variable as described in the next point, or adjust Window's system path to include the absolute path to the compiler'sbindirectory.If using multiple versions of the Wind River (Diab) compiler (for instance, when you are using two or more versions of OpenECU which require different versions of the Wind River (Diab) compiler), the environment variable

OPENECU_DIAB_5_8must be set to the absolute path to the compiler'sbindirectory. This macro must terminate in a “\” and must use the DOS 8.3 short naming convention.E.g.,

D:\Progra~1\diab\5_8_0_0\win32\bin\Note

After setting the environment variable, MATLAB may need to be restarted to pick up the new setting. If in doubt, issue the:

oe_check_compiler

command at MATLAB's prompt to check that the environment variable is correctly setup and the compiler is available.

Closed: Can't use Simulink look up blocks

There has been a known issue which restricts the compiler to use Simulink lookup block. When using Simulink lookup blocks, the Diab compiler would stop compilation with this error message:

'[model-name].c', line [line-num]: warning (dcc:1792): trying to assign 'ptr to volatile' to 'ptr'This has now been fixed, see F-CR 13325 in the release notes.

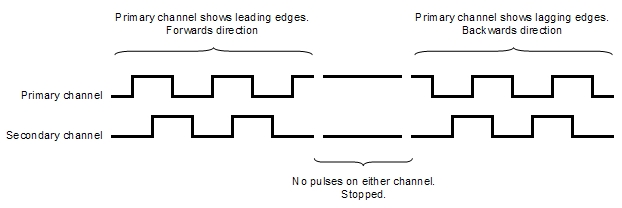

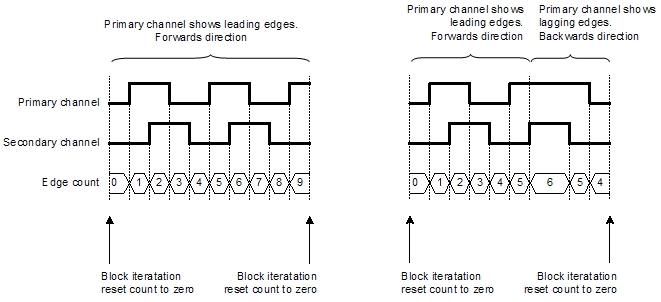

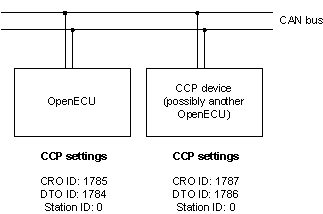

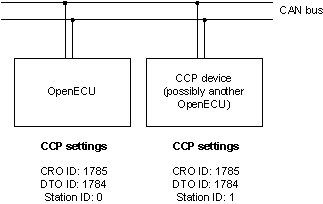

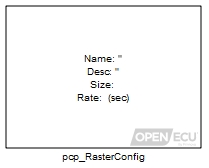

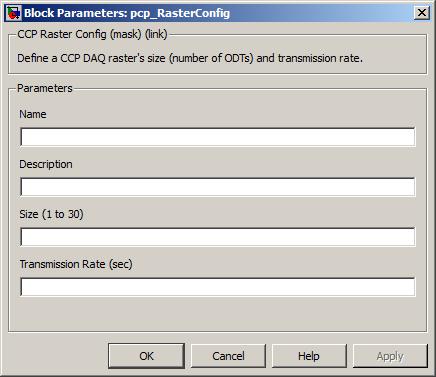

The Wind River (Diab) compiler 5.9.0.0 can be installed by running the file