Release 2.9.0 (r2020-1)

Copyright © 2020 Pi Innovo

13-Apr-2020

Table of Contents

- 1. Technical specification

- 2. Connector pinout

- 3. Internal signals

- 4. Operational details

- 4.1. ECU power

- 4.2. ECU power — control

- 4.3. ECU power — actuator supplies

- 4.4. ECU power — sensor supplies

- 4.5. Analogue inputs

- 4.6. Analogue inputs — ratiometric measurement

- 4.7. Analogue inputs — internal temperature input

- 4.8. Relationship between VREF, sensor supplies and inputs

- 4.9. Digital inputs

- 4.10. Digital outputs

- 4.11. Digital output — state monitoring

- 4.12. Digital output — driver protection

- 4.13. Digital output — high-side actuator output control

- 4.14. Digital output — high-side actuator output diagnostics

- 4.15. Digital output — injector operation

- 4.16. Digital output — configurable injector outputs

- 4.17. H-bridge outputs

- 4.18. Serial inputs and outputs

- 4.19. Communication — CAN

- 4.20. Memory — configuration

- 4.21. Memory — non-volatile storage and lifetime

- 4.22. Memory — calibration capabilities

- 4.23. System modes

- 4.24. Flash codes

- 4.25. Calibration capabilities

- 4.26. Floating point capabilities

- 5. Dimensions

- A. Contact information

List of Figures

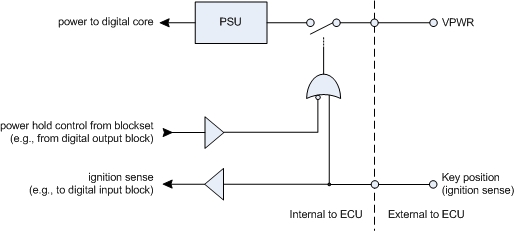

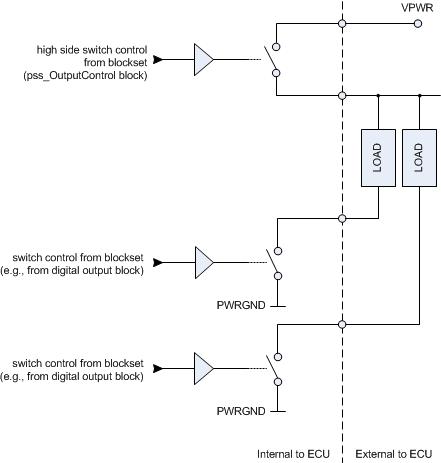

- 4.1. Switching arrangement for main power supply

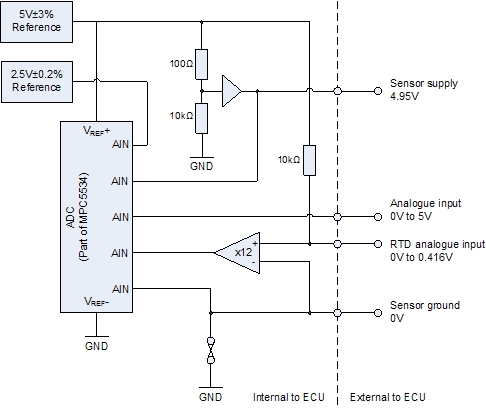

- 4.2. VREF arrangement

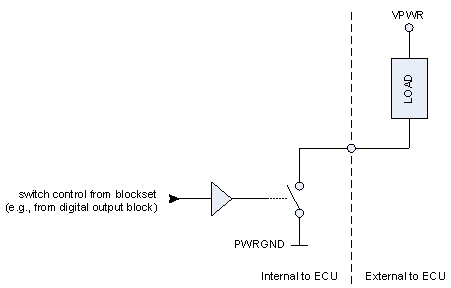

- 4.3. Low-side switching arrangement for digital outputs

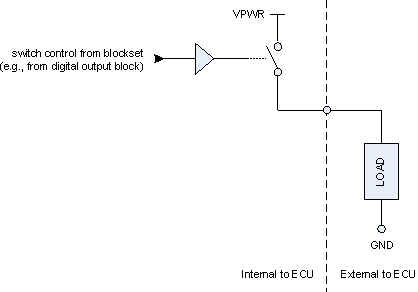

- 4.4. High-side switching arrangement for digital outputs

- 4.5. Switched output control for digital outputs

- 4.6. High-side actuator output diagnostic

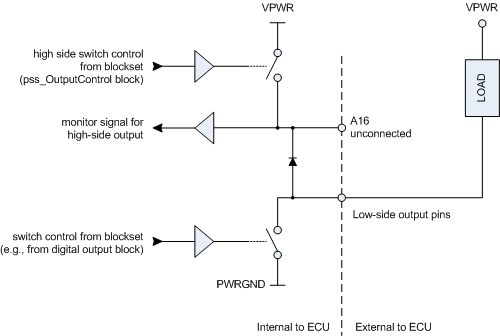

- 4.7. Injector operation

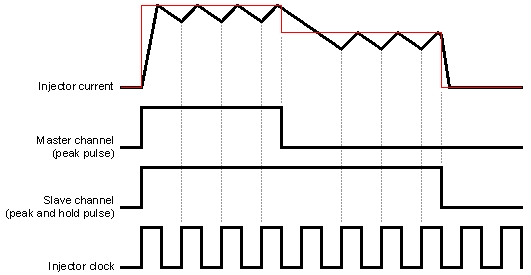

- 4.8. H-bridge arrangement

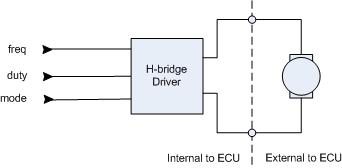

- 4.9. Flash code sequence

- 5.1. Outline of physical dimensions

List of Tables

- 1.1. Specification

- 1.2. Function reference

- 2.1. Part numbers of the mating connector

- 2.2. Part numbers for the 6.3 mm pin

- 2.3. Part numbers for the 2.8 mm pin

- 2.4. Part numbers for the 0.64 mm pin

- 2.5. Part numbers of the pin crimp tools

- 2.6. Connector pinout — Pocket A

- 3.1. Internal signals

- 4.1. PSU 1 and 2 monitor voltages

- 4.2. Sensor ground monitor voltage

- 4.3. Internal temperature input

- 4.4. Low-side digital output leakage current

- 4.5. Memory configurations supported

- 4.6. System mode selection

- 4.7. Flash code example

- 4.8. Flash codes

- 4.9. Floating point conditions

This document is the technical specification for OpenECU part 01T-068276-03M05-000 or greater. Within this document, that part is referred to as M250-000.

Note

For a list of issues and possible work arounds for this ECU, found after publication of this document, please refer to the hardware errata for this ECU (named 29T-068276ER-xE M250 Technical Spec Errata).

Specific option control may exist for this part. In that case, parts of this document will be overridden by an option control specific technical specification. Please refer to the option control technical specification for more information.

This technical specification relates to the following ECU variant:

M250D-000 — for development and testing, including full interactive calibration tool integration.

Table 1.1. Specification

| Specification | Variant |

|---|---|

| M250D-000 | |

| Status | Available [a] |

| Processor | MPC5534 |

| Rate | 80MHz |

| Code space | up to 768KiB [b] |

| RAM space | up to 832KiB [b] |

| Calibration space | up to 256KiB [b] |

| Calibratable | Y |

| Reprogrammable | Y |

| Power control relays | - |

| Actuator supplies | 1 |

| Sensor supplies | 2 |

| Inputs | 19 |

| Outputs | 13 |

| CAN buses | 2 |

| LIN buses | - |

| RS232 links | - |

| Connectors | 1x46 |

| Weight | 1.1Kg |

| Vibration | Ford class IIIB |

| Shock capability | Ford class II |

| Enclosure | IP67 [c] |

| EMC | Ford EMC CS 2009, category AX |

| Partial operating voltage | 6 to 36V [d] |

| Full operating voltage | 6.5 to 36V [e] |

| Standby current (typical) | <0.01mA at 12V [f] |

| Operating current (typical) | 200mA at 12V [g] |

| Operating temperature range | -40 to +105°C |

| Storage temperature range (installation) | -40 to +120°C |

| Storage temperature range (shipping) | -40 to +85°C |

[a] Target ECU available for general use. [b] See list of possible memory configurations in section 'Memory - configuration'. [c] Designed for chassis mounted applications. [d] At room temperature [e] Designed for 12V or 24V vehicles. [f] <0.01mA at 24V. [g] 125mA at 24V. When running idle task with I/O disconnected. | |

Various input and output functionality is supported where some pins may be capable of more than one function. Some functions require a combination of pins but not all pin combinations are possible.

Table 1.2. Function reference

| I/O type | External | Internal | Pins |

|---|---|---|---|

| Power | |||

| ECU supply | 1 | - | A2 |

| ECU ground | 1 | - | A31 |

| Actuator supply | 1 | - | A16 |

| Sensor supply | 2 | - | A25, A39 |

| Module control, status | |||

| Ignition sense | 1 | - | A26 |

| Module control FEPS | 1 | - | A27 |

| Module status Flash code | 1 | - | A27 |

| Communication | |||

| CAN buses | 2 | - | A28+A43, A29+A44 |

| Inputs — time based | |||

| Analogue | 19 | 32 | A3, A4, A5, A6, A7, A8, A9, A10, A11, A12, A13, A14, A15, A19, A20, A21, A22, A23, A24 |

| Digital | 7 | 23 | A10, A11, A12, A13, A14, A15, A26 |

| Frequency | 6 | 12 | A10, A11, A12, A13, A14, A15 |

| PWM | 6 | - | A10, A11, A12, A13, A14, A15 |

| Quadrature | 6 | - | A10, A11, A12, A13, A14, A15 |

| Outputs — time based | |||

| Digital | 11 | 9 | A1, A17, A18, A30, A32, A33, A34, A35, A36, A45, A46 |

| H-bridge | 2 | - | A17+A46, A30+A1 |

| PWM | 11 | 6 | A1, A17, A18, A30, A32, A33, A34, A35, A36, A45, A46 |

| PWM synchronised | 3 | - | A32, A33, A34 |

| Inputs — angle based | |||

| Crank-shaft primary | 1 | - | A10 |

| Cam-shaft | 1 | - | A11 |

| Analogue | 19 | 64 | A3, A4, A5, A6, A7, A8, A9, A10, A11, A12, A13, A14, A15, A19, A20, A21, A22, A23, A24 |

| Analogue injector duration | 14 | - | A3, A4, A5, A6, A7, A8, A9, A14, A15, A19, A21, A22, A23, A24 |

| Outputs — angle based | |||

| Injector saturating | 6 | - | A32, A33, A34, A35, A36, A45 |

| Ignition | 7 | - | A18, A32, A33, A34, A35, A36, A45 |

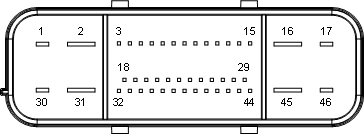

The M250-000 variants have one ECU connector (pocket) named A, which has a pinout as given in the following table. Currents listed are RMS unless otherwise stated.

The following abbreviations are used in the pinout tables below:

C Communication I Input M Monitor O Output P Power

CT Current trip GND Ground PSU Power supply PWR Power RTD Resistance temperature detector

Connector packs can be ordered from Pi. Individual connector components can be ordered from Pi or from various manufacturers.

Table 2.1. Part numbers of the mating connector

| Supplier | Part number | Part |

|---|---|---|

| TE | 1326110-1 | Cable mount connector (right handed) |

| 1326341-1 | Cable mount connector (left handed) | |

| 1326113-1 | Cover |

Table 2.3. Part numbers for the 2.8 mm pin

| Supplier | Part number | Colour | Part |

|---|---|---|---|

| TE | 1326032-4 | Tin | Female crimp contact |

| Yazaki | 7158-3111-60 | Green | Seal (for wire 1.19 mm - 1.90 mm) |

| 7158-3112-70 | Yellow | Seal (for wire 1.88 mm - 2.10 mm) | |

| 7158-3113-40 | White | Seal (for wire 2.18 mm - 3.00 mm) | |

| 7158-3114-90 | Blue | Plug for unused position | |

| Pins A1, A17, A30 and A46 | |||

Table 2.5. Part numbers of the pin crimp tools

| Supplier | Tool assembly part number | Die assembly part number | Part |

|---|---|---|---|

| TE | 91338-1 | 91338-2 | Crimp tool for the 0.64 mm female terminal, PRO-CRIMPER III Hand Tool |

| Diamond Die and Mold Company | 088BR | - | Crimp tool for the 2.8 mm female terminal |

| 088BR-1 | Crimp tool for the 6.3 mm female terminal |

Table 2.6. Connector pinout — Pocket A

| Main connector — Pocket A | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pin | P | Function | I/O | M | Loading | Filter | Range | Notes |

| A1 | Digital | O | Y | Low-high side | 8A | Related to internal channels DOT select-high-side, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Associated with A30 if configured as an H-bridge output; otherwise, it can be selected to be a low-side or high-side output. Range given is for a resistive load. For inductive loads this rating may need to be reduced depending on inductance, duty cycle and operating temperature. Related to internal channels DOT select-high-side, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||||||||

| A2 | VPWR | P | Y | 40A | Related to internal channel AIN VPWR. | |||

| A3 | Analogue (RTD) | I | 10k to 5V | 1.72KHz | 0mV to 416.7mV | 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*0.08334. | ||

| A4 | Analogue (RTD) | I | 10k to 5V | 1.72KHz | 0mV to 416.7mV | 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*0.08334. | ||

| A5 | Analogue (RTD) | I | 10k to 5V | 1.72KHz | 0mV to 416.7mV | 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*0.08334. | ||

| A6 | Analogue (RTD) | I | 10k to 5V | 1.72KHz | 0mV to 416.7mV | 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*0.08334. | ||

| A7 | Analogue (RTD) | I | 10k to 5V | 1.72KHz | 0mV to 416.7mV | 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*0.08334. | ||

| A8 | Analogue (RTD) | I | 10k to 5V | 1.72KHz | 0mV to 416.7mV | 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*0.08334. | ||

| A9 | Analogue (RTD) | I | 10k to 5V | 1.72KHz | 0mV to 416.7mV | 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*0.08334. | ||

| A10 | Digital | I | 4k7 to VPWR through diode | 7.8kHz | 0V to VPWR | Crank-shaft position sensor. VLH >= 3.5V VHL <= 1.5V. | ||

| Analogue | 100Hz | 0V to 5V | 12-bit unsigned conversion. | |||||

| A11 | Digital | I | 4k7 to VPWR through diode | 7.8kHz | 0V to VPWR | Cam-shaft position sensor. VLH >= 3.5V VHL <= 1.5V. | ||

| Analogue | 100Hz | 0V to 5V | 12-bit unsigned conversion. | |||||

| A12 | Digital | I | 4k7 to VPWR through diode | 7.8kHz | 0V to VPWR | VLH >= 3.5V VHL <= 1.5V. | ||

| Analogue | 100Hz | 0V to 5V | 12-bit unsigned conversion. | |||||

| A13 | Digital | I | 4k7 to VPWR through diode | 7.8kHz | 0V to VPWR | VLH >= 3.5V VHL <= 1.5V. | ||

| Analogue | 100Hz | 0V to 5V | 12-bit unsigned conversion. | |||||

| A14 | Digital | I | 4k7 to VPWR through diode | 7.8kHz | 0V to VPWR | VLH >= 3.5V VHL <= 1.5V. | ||

| Analogue | 100Hz | 0V to 5V | 12-bit unsigned conversion. | |||||

| A15 | Digital | I | 4k7 to VPWR through diode | 7.8kHz | 0V to VPWR | VLH >= 3.5V VHL <= 1.5V. | ||

| Analogue | 100Hz | 0V to 5V | 12-bit unsigned conversion. | |||||

| A16 | Actuator supply | P | Y | High side | 20A | High side actuator power. Related to internal channels Monitor (ct), Monitor (d) and Monitor (v). | ||

| A17 | Digital | O | Y | Low-high side | 8A | Related to internal channels DOT select-high-side, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Associated with A46 if configured as an H-bridge output; otherwise, it can be selected to be a low-side or high-side output. Range given is for a resistive load. For inductive loads this rating may need to be reduced depending on inductance, duty cycle and operating temperature. . Related to internal channels DOT select-high-side, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||||||||

| A18 | Digital | O | Y | Low side | 500mA | Related to internal channels Monitor (d) and Monitor (v). | ||

| Coil/spark (smart) driver. Related to internal channels Monitor (d) and Monitor (v). | ||||||||

| A19 | Analogue | I | 51k to VGND | 99Hz | 0V to 5V | 12-bit unsigned conversion. | ||

| A20 | Analogue | I | 51k to VGND | 99Hz | 0V to 5V | 12-bit unsigned conversion. | ||

| A21 | Analogue | I | 51k to VGND | 99Hz | 0V to 5V | 12-bit unsigned conversion. | ||

| A22 | Analogue | I | 51k to VGND | 99Hz | 0V to 5V | 12-bit unsigned conversion. | ||

| A23 | Analogue | I | 51k to VGND | 99Hz | 0V to 5V | 12-bit unsigned conversion. | ||

| A24 | Analogue | I | 51k to VGND | 99Hz | 0V to 5V | 12-bit unsigned conversion. | ||

| A25 | Sensor supply | P | Y | 5V, 250mA | Sensor supply 1. Can be turned on and off by the application for diagnostics purposes. Related to internal channels DOT disable-EXT-PSU1 and Monitor (v). | |||

| A26 | Digital | I | 4k7 to VGND | 258Hz | 0V to VPWR | Key position (ignition sense) input. VLH >= 4.55V VHL <= 3.95V. Related to internal channel DOT disable-PSU-hold. | ||

| A27 | FEPS | I | 82K series followed by bias of 10K to 5V and 11K to VGND | 323Hz | ±18V | Module flash programming control. Mutually exclusive use with Flash code output function. You can not connect both at the same time. | ||

| Flash code | O | Low side | 10mA | ECU status information. Mutually exclusive use with FEPS input function. You can not connect both at the same time. | ||||

| A28 | CAN+ (high) | C | No termination resistor | CAN bus 0 high (+ve), see also: A43. Related to internal channel DOT disable-CAN. | ||||

| A29 | CAN+ (high) | C | 124R | CAN bus 1 high (+ve), see also: A44. Related to internal channel DOT disable-CAN. | ||||

| A30 | Digital | O | Y | Low-high side | 8A | Related to internal channels DOT select-high-side, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Associated with A1 if configured as an H-bridge output; otherwise, it can be selected to be a low-side or high-side output. Range given is for a resistive load. For inductive loads this rating may need to be reduced depending on inductance, duty cycle and operating temperature. Related to internal channels DOT select-high-side, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||||||||

| A31 | VGND | P | 40A | |||||

| A32 | Digital (injector) | O | Y | Low side | 5A/2A | The pin function (injector or digital) is software selectable. Related to internal channels DOT injector-clock, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Digital | Coil/spark (smart) driver. Related to internal channels DOT injector-clock, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | |||||||

| A33 | Digital (injector) | O | Y | Low side | 5A/2A | The pin function (injector or digital) is software selectable. Related to internal channels DOT injector-clock, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Digital | Coil/spark (smart) driver. Related to internal channels DOT injector-clock, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | |||||||

| A34 | Digital (injector) | O | Y | Low side | 5A/2A | The pin function (injector or digital) is software selectable. Related to internal channels DOT injector-clock, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Digital | Coil/spark (smart) driver. Related to internal channels DOT injector-clock, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | |||||||

| A35 | Digital (injector) | O | Y | Low side | 2A | Related to internal channels Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Digital | ||||||||

| A36 | Digital (injector) | O | Y | Low side | 8A | Related to internal channels Monitor (ct), Monitor (d) and Monitor (v). | ||

| Digital | ||||||||

| Although this output can be used for PWM drive, no recirculation diode is fitted in the standard hardware. Related to internal channels Monitor (ct), Monitor (d) and Monitor (v). | ||||||||

| A37 | No function. | |||||||

| A38 | No function. | |||||||

| A39 | Sensor supply | P | Y | 5V, 250mA | Sensor supply 2. Can be turned on and off by the application for diagnostics purposes. Related to internal channels DOT disable-EXT-PSU2 and Monitor (v). | |||

| A40 | Sensor ground | P | Y | A40 and A41 connected together internally. Related to internal channel AIN extern-ground. | ||||

| A41 | Sensor ground | P | Y | A40 and A41 connected together internally. Related to internal channel AIN extern-ground. | ||||

| A42 | No function. | |||||||

| A43 | CAN- (low) | C | No termination resistor | CAN bus 0 low (-ve), see also: A28. Related to internal channel DOT disable-CAN. | ||||

| A44 | CAN- (low) | C | 124R | CAN bus 1 low (-ve), see also: A29. Related to internal channel DOT disable-CAN. | ||||

| A45 | Digital (injector) | O | Y | Low side | 10A | Related to internal channels Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Digital | ||||||||

| A46 | Digital | O | Y | Low-high side | 8A | Related to internal channels DOT select-high-side, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||

| Associated with A17 if configured as an H-bridge output; otherwise, it can be selected to be a low-side or high-side output. Range given is for a resistive load. For inductive loads this rating may need to be reduced depending on inductance, duty cycle and operating temperature. Related to internal channels DOT select-high-side, Monitor (c), Monitor (ct), Monitor (d) and Monitor (v). | ||||||||

Table 3.1. Internal signals

| Signal | I/O | Signal type | Range | Notes |

|---|---|---|---|---|

| Analogue | ||||

| AIN internal-ecu-temp | I | Analogue | 241mV to 4981mV | Internal ECU temperature measurement. Conversion from voltage to temperature is non-linear and specified by a look-up table. 12-bit unsigned conversion. |

| AIN PSU+2.5VD | I | Analogue | 0V to 5V | Internal 2.5V precision reference. 12-bit unsigned conversion. |

| AIN VRH | I | Analogue | 0V to 5V | 5V reference for analogue input conversions. 12-bit unsigned conversion. |

| AIN VRH-VRL 25% | I | Analogue | 0V to 5V | 1.25V reference for analogue input conversions. 12-bit unsigned conversion. |

| AIN VRH-VRL 50% | I | Analogue | 0V to 5V | 2.5V reference for analogue input conversions. Will read as 2.48V due to 20mV offset in processor implementation. 12-bit unsigned conversion. |

| AIN VRH-VRL 75% | I | Analogue | 0V to 5V | 3.75V reference for analogue input conversions. 12-bit unsigned conversion. |

| AIN VRL | I | Analogue | 0V to 5V | 0V reference for analogue input conversions. 12-bit unsigned conversion. |

| Current monitor | ||||

| Monitor (c) (pin A1) | I | Analogue | ±12.5A | Digital output current monitor. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=(V-2.5)*5. |

| Monitor (c) (pin A17) | I | Analogue | ±12.5A | Digital output current monitor. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=(V-2.5)*5. |

| Monitor (c) (pin A30) | I | Analogue | ±12.5A | Digital output current monitor. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=(V-2.5)*5. |

| Monitor (c) (pin A32) | I | Analogue | 0A to 6.25A | Digital output current monitor. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=V*1.25. |

| Monitor (c) (pin A33) | I | Analogue | 0A to 6.25A | Digital output current monitor. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=V*1.25. |

| Monitor (c) (pin A34) | I | Analogue | 0A to 6.25A | Digital output current monitor. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=V*1.25. |

| Monitor (c) (pin A35) | I | Analogue | 0A to 2.5A | Digital output current monitor. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=V*0.5. |

| Monitor (c) (pin A45) | I | Analogue | 0A to 12.5A | Digital output current monitor with 884Hz filter. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=V*2.5. |

| Monitor (c) (pin A46) | I | Analogue | ±12.5A | Digital output current monitor. 12-bit unsigned conversion. To convert voltage (V) to current (I) use the equation, I=(V-2.5)*5. |

| Current trip monitor | ||||

| Monitor (ct) (pin A1) | I | Digital | 0 or 1 | Digital input indicating current trip. The input is guaranteed to trip when I < -9.95A or I > 10.85A, and will not trip when -8.0A <= I <= 8.0A. Serial input. |

| Monitor (ct) (pin A16) | I | Digital | 0 or 1 | Digital input indicating current trip. The input is guaranteed to trip when I > 26.5A, and will not trip when I <= 20A. Serial input. |

| Monitor (ct) (pin A17) | I | Digital | 0 or 1 | Digital input indicating current trip. The input is guaranteed to trip when I < -9.95A or I > 10.85A, and will not trip when -8.0A <= I <= 8.0A. Serial input. |

| Monitor (ct) (pin A30) | I | Digital | 0 or 1 | Digital input indicating current trip. The input is guaranteed to trip when I < -9.95A or I > 10.85A, and will not trip when -8.0A <= I <= 8.0A. Serial input. |

| Monitor (ct) (pin A32) | I | Digital | 0 or 1 | Digital input indicating current trip. Hold: Guaranteed to trip when I > 2.35A, and will not trip when I <= 1.75A. Peak: Guaranteed to trip when I > 5.8A, and will not trip when I <= 5.0A. Serial input. |

| Monitor (ct) (pin A33) | I | Digital | 0 or 1 | Digital input indicating current trip. Hold: Guaranteed to trip when I > 2.35A, and will not trip when I <= 1.75A. Peak: Guaranteed to trip when I > 5.8A, and will not trip when I <= 5.0A. Serial input. |

| Monitor (ct) (pin A34) | I | Digital | 0 or 1 | Digital input indicating current trip. Hold: Guaranteed to trip when I > 2.35A, and will not trip when I <= 1.75A. Peak: Guaranteed to trip when I > 5.8A, and will not trip when I <= 5.0A. Serial input. |

| Monitor (ct) (pin A35) | I | Digital | 0 or 1 | Digital input indicating current trip. The input is guaranteed to trip when I > 11.6A, and will not trip when I <= 10.0A. Serial input. |

| Monitor (ct) (pin A36) | I | Digital | 0 or 1 | Digital input indicating current trip. The input is guaranteed to trip when I >= 11.0A, and will not trip when I <= 8.2A. Serial input. |

| Monitor (ct) (pin A45) | I | Digital | 0 or 1 | Digital input indicating current trip. The input is guaranteed to trip when I > 11.6A, and will not trip when I <= 10.0A. Serial input. |

| Monitor (ct) (pin A46) | I | Digital | 0 or 1 | Digital input indicating current trip. The input is guaranteed to trip when I < -9.95A or I > 10.85A, and will not trip when -8.0A <= I <= 8.0A. Serial input. |

| Digital | ||||

| DOT disable-CAN (pin A28 and A43) | O | Digital | 0 or 1 | Set to zero to enable CAN transmission, set to one to disable. |

| DOT disable-CAN (pin A29 and A44) | O | Digital | 0 or 1 | Set to zero to enable CAN transmission, set to one to disable. |

| DOT disable-EXT-PSU1 (pin A25) | O | Digital | 0 or 1 | Sensor supply switch. Set to zero to turn on the power supply and to one to turn it off. |

| DOT disable-EXT-PSU2 (pin A39) | O | Digital | 0 or 1 | Sensor supply switch. Set to zero to turn on the power supply and to one to turn it off. |

| DOT disable-PSU-hold (pin A26) | O | Digital | 0 or 1 | Control power supply to ECU in conjunction with the key position (ignition sense) input. Set the output to zero to enable power hold and one to disable it. |

| DOT injector-clock (pin A32) | O | Digital | 0 or 1 | PWM clock signal for injector (no effect if A32 is configured for PWM mode). |

| DOT injector-clock (pin A33) | O | Digital | 0 or 1 | PWM clock signal for injector (no effect if A33 is configured for PWM mode). |

| DOT injector-clock (pin A34) | O | Digital | 0 or 1 | PWM clock signal for injector (no effect if A34 is configured for PWM mode). |

| DOT select-high-side (pin A1) | O | Digital | 0 or 1 | Set to zero to select low-side, set to one to select high-side. |

| DOT select-high-side (pin A17) | O | Digital | 0 or 1 | Set to zero to select low-side, set to one to select high-side. |

| DOT select-high-side (pin A30) | O | Digital | 0 or 1 | Set to zero to select low-side, set to one to select high-side. |

| DOT select-high-side (pin A46) | O | Digital | 0 or 1 | Set to zero to select low-side, set to one to select high-side. |

| Digital monitor | ||||

| Monitor (d) (pin A1) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A16) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A17) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A18) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A30) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A32) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A33) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A34) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A35) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A36) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A45) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Monitor (d) (pin A46) | I | Digital | 0 or 1 | Digital output state monitor. VLH >= 6.95V VHL <= 3.25V. |

| Memory check | ||||

| Monitor (counter eTPU background task) | I | Digital data | 0 to 65535 | Cyclic counter providing number of times the eTPU background task runs. Its rate of increase can be used to determine the rate of the background task. |

| Monitor (fc SDM-checksum) | I | Digital data | 0 to 65535 | Saturating counter providing number of times the eTPU module's data memory failed a checksum test. |

| Voltage monitor | ||||

| AIN extern-ground (pin A40 and A41) | I | Analogue | 0V to 5V | Sensor ground voltage monitor. 12-bit unsigned conversion. |

| AIN VPWR (pin A2) | I | Analogue | 0V to 40V | Switched power supply voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*8. |

| Monitor (v) (pin A1) | I | Analogue | 0V to 33V | Digital output voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A16) | I | Analogue | 0V to 33V | Digital output voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A17) | I | Analogue | 0V to 33V | Digital output voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A18) | I | Analogue | 0V to 33V | Digital output voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A25) | I | Analogue | 0V to 5V | Sensor supply voltage monitor. 12-bit unsigned conversion. |

| Monitor (v) (pin A30) | I | Analogue | 0V to 33V | Digital output voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A32) | I | Analogue | 0V to 33V | Digital output voltage monitor with 884Hz filter. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A33) | I | Analogue | 0V to 33V | Digital output voltage monitor with 884Hz filter. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A34) | I | Analogue | 0V to 33V | Digital output voltage monitor with 884Hz filter. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A35) | I | Analogue | 0V to 33V | Digital output voltage monitor with 884Hz filter. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A36) | I | Analogue | 0V to 33V | Digital output voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A39) | I | Analogue | 0V to 5V | Sensor supply voltage monitor. 12-bit unsigned conversion. |

| Monitor (v) (pin A45) | I | Analogue | 0V to 33V | Digital output voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

| Monitor (v) (pin A46) | I | Analogue | 0V to 33V | Digital output voltage monitor. 12-bit unsigned conversion. To convert measured voltage (Vm) to actual voltage (Va) use the equation, Va=Vm*33/5. |

- 4.1. ECU power

- 4.2. ECU power — control

- 4.3. ECU power — actuator supplies

- 4.4. ECU power — sensor supplies

- 4.5. Analogue inputs

- 4.6. Analogue inputs — ratiometric measurement

- 4.7. Analogue inputs — internal temperature input

- 4.8. Relationship between VREF, sensor supplies and inputs

- 4.9. Digital inputs

- 4.10. Digital outputs

- 4.11. Digital output — state monitoring

- 4.12. Digital output — driver protection

- 4.13. Digital output — high-side actuator output control

- 4.14. Digital output — high-side actuator output diagnostics

- 4.15. Digital output — injector operation

- 4.16. Digital output — configurable injector outputs

- 4.17. H-bridge outputs

- 4.18. Serial inputs and outputs

- 4.19. Communication — CAN

- 4.20. Memory — configuration

- 4.21. Memory — non-volatile storage and lifetime

- 4.22. Memory — calibration capabilities

- 4.23. System modes

- 4.24. Flash codes

- 4.25. Calibration capabilities

- 4.26. Floating point capabilities

The power supply pin (VPWR A2) and the ground pin (VGND A31) are both rated to 40A.

The ECU is designed for 12V or 24V vehicles and will operate over the range 6.5V to 36V. The ECU is protected against reverse supply connection (for at least 60 seconds). All inputs and outputs are protected against short-to-VPWR or short-to-VGND over normal operating range.

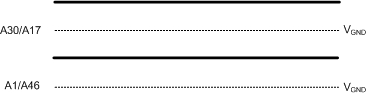

The ECU power arrangement is shown in Figure 4.1, “Switching arrangement for main power supply”.

The ECU is powered up when the power supply pins (VPWR A2) and key position (ignition sense) input (pin A26) are asserted. The key position input (pin A26) can be read as a digital input.

This arrangement allows for the ECU application software to hold the ECU on after the external key position input is opened, allowing, for example, non-volatile memory processing to occur. For the ECU to hold power the internal DOT disable-PSU-hold channel needs to be asserted. Setting this internal channel low will hold power when the key position input is opened, setting it high will allow the ECU to power off when the key position input is opened.

Note

When using the 'power hold' functionality, it is best to set the internal DOT disable-PSU-hold channel low as soon as the external key position input (pin A26) is closed and only set high once all required shutdown tasks have completed.

The ECU can provide power to actuators through a high-side power pin (A16) and control if this pin is asserted or not. See Section 4.13, “Digital output — high-side actuator output control” for further details.

The ECU provides two external sensor power supplies (pins A25 and A39). Each sensor supply can be switched off by setting the appropriate internal channel (DOT disable-EXT-PSU1 or DOT disable-EXT-PSU2) to one, to allow the application software to perform intrusive diagnostics on sensors.

Each output is monitored by an internal analogue input channel which can be used to check for short circuits and measure the exact output voltage for use with ratiometric sensors.

The output voltage is guaranteed to never reach full scale in normal operation, hence a full scale indication should be taken to indicate a suspected short to battery. The value read from the voltage monitor when the corresponding PSU is enabled should be interpreted as follows:

Table 4.1. PSU 1 and 2 monitor voltages

| Voltage [a] | Meaning |

|---|---|

| 4.975V - 5.00V | Output shorted to battery |

| 4.925V - 4.975V | Normal operation |

| 0V - 4.925V | Output over current or short to ground |

[a] These voltages are based on absolute A/D counts (referenced to the ECU's internal 5V supply) and should not be adjusted ratiometrically against the ECU's 2.5V reference (internal channel AIN PSU+2.5VD). This is only from the perspective of diagnostic. For the purpose of end measurement accuracy and voltage reporting all adjustments should be applied. | |

The value read from the common sensor ground voltage monitor should be interpreted as follows:

Table 4.2. Sensor ground monitor voltage

| Voltage | Meaning |

|---|---|

| 0mV - 220mV | Normal Operation |

| > 220mV | Output over current or short to battery |

The sensor ground feedback can also be used in normal operation by the application software to provide a precision ground reference for ratiometric measurements.

The analogue inputs (pins A3, A4, A5, A6, A7, A8, A9, A10, A11, A12, A13, A14, A15, A19, A20, A21, A22, A23 and A24) sample voltage with varying resolution and range. See the pin information for more details. Some of the analogue inputs have additional characteristics, as detailed in the following sections.

Note

If any of the pins A1, A17, A18, A30, A32, A33, A34, A35, A45 and A46 are not being used as digital outputs then it is possible for them to be used as analogue inputs with a range of 0V to 33V, a loading of 41.5K to ground and a filter of 93Hz. Providing the output transistor is switched off, the pin can be driven by an external source and pin's voltage monitor will reflect the actual voltage on the pin.

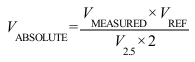

Ratiometric sensors are read in as a ratio between the sensor and reference voltages (Vsens/Vref). Correction is only required on channels for which an absolute voltage measurement is required. Correction is not required for sensors supplied from the 5V sensor supply and which produce an output that is ratiometric to the supply.

To read a variable sensor which is an absolute referenced sensor (Vsens,Vabs) the Vref for the ADC requires correction:

Where VMEASURED is the A/D conversion for an external pin, VREF is the A/D conversion for internal channel AIN VRH, V2.5 is the A/D conversion for internal channel AIN PSU+2.5VD, and 2 is a constant.

The ECU has an internal temperature sensor. The relationship between temperature and the ADC voltage (VADC) for the internal temperature sensor is non-linear. The temperature over a range of -55°C to +150°C correlates to voltage by Table 4.3, “Internal temperature input”.

Table 4.3. Internal temperature input

| Temperature (°C) | Voltage (V) | Temperature (°C) | Voltage (V) |

|---|---|---|---|

| -55 | 4.981 | 50 | 2.499 |

| -50 | 4.973 | 55 | 2.265 |

| -45 | 4.962 | 60 | 2.041 |

| -40 | 4.947 | 65 | 1.830 |

| -35 | 4.927 | 70 | 1.634 |

| -30 | 4.900 | 75 | 1.454 |

| -25 | 4.866 | 80 | 1.290 |

| -20 | 4.821 | 85 | 1.143 |

| -15 | 4.765 | 90 | 1.011 |

| -10 | 4.694 | 95 | 0.893 |

| -5 | 4.608 | 100 | 0.789 |

| 0 | 4.504 | 105 | 0.698 |

| 5 | 4.379 | 110 | 0.617 |

| 10 | 4.234 | 115 | 0.546 |

| 15 | 4.068 | 120 | 0.483 |

| 20 | 3.882 | 125 | 0.429 |

| 25 | 3.676 | 130 | 0.381 |

| 30 | 3.456 | 135 | 0.339 |

| 35 | 3.223 | 140 | 0.302 |

| 40 | 2.983 | 145 | 0.269 |

| 45 | 2.740 | 150 | 0.241 |

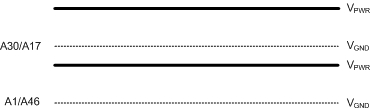

The ECU power arrangement is shown in Figure 4.2, “VREF arrangement”. The figure shows the relationship between the internal 5V VREF and ground, the external sensor supply and ground, and the analogue inputs.

The internal low precision 5V reference supplies the reference pin on the ADC. A high precision 2.5V reference can be read on a direct (unscaled) ADC channel. This can be used to calculate the true value of the 5V reference and subsequently used to improve accuracy on all other channels. The 5V reference is divided down to 4.95V to provide the external sensor supply. The exact voltage being produced can be read on a direct (unscaled) ADC channel. The sensor ground is a nominal 0V, but may be slightly above this due to voltage drop across the protection device.

The exact voltage on the pin can be read on a direct (unscaled) ADC channel. Standard 0-5V inputs are passed directly to the ADC with no scaling. RTD analogue inputs have a 10K pullup to the internal reference voltage. The voltage difference between the input and sensor ground is amplified by a gain of 12 and then passed to an ADC input.

The digital inputs (pins A10, A11, A12, A13, A14 and A15) sense the binary state based on the pin voltage and a threshold.

Note

The external digital signals are all low pass filtered to prevent signals of excessive frequency from tying up the target processor (e.g. to prevent spurious interrupts occurring from high frequency noise coupling).

Note

If any of the pins A1, A17, A18, A30, A32, A33, A34, A35, A45 and A46 are not being used as digital outputs then it is possible for them to be used as digital inputs with a loading of 41.5K to ground and no input filter. Providing the output transistor is switched off, the pin can be driven by an external source and the pin's digital monitor will reflect the actual state of the pin. The digital monitor signal is not inverted: low if <= 3.3V and high if >= 6.9V, with a hysteresis >= 0.2V.

The digital outputs (pins A1, A17, A18, A30, A32, A33, A34, A35, A36, A45 and A46) can be used as low-side drivers. That is, the ECU switches the output pin to ground, the actuator is connected to the output pin and the battery (or to the ECU's high-side power pin, A16, see Section 4.13, “Digital output — high-side actuator output control” for further details).

The low-side digital outputs contain internal monitoring circuitry that provides diagnostic information. However, as a consequence a small leakage current will flow through the actuator when the low-side output driver is turned off. Refer to Table 4.4, “Low-side digital output leakage current” for typical leakage currents at specified operating voltages.

Table 4.4. Low-side digital output leakage current

| Supply Voltage (V) | Typical Leakage Current (mA) |

|---|---|

| 12 | 0.400 |

| 24 | 0.800 |

Warning

The digital outputs are not guaranteed to work properly when the ECU supply (battery) is outside 7V - 32V. It is recommended to monitor the ECU supply voltage on A2 and set the digital outputs to a safe state in your application software. The safe state depends on your application. In most applications, the safe state is to disable the outputs to protect the circuitry and to prevent unwanted output activation.

Note

The H-Bridge pins (pins A17+A46 and A30+A1) can be used independently either as high-side or low-side pins. Drivers are configured as low-side or high-side by setting the corresponding internal channels (e.g., DOT select-high-side).

Note

Pin A36 uses an IGBT output transistor and can be used to drive a spark coil, the rest of the outputs use MOSFETs.

When a pin is configured as a high-side, the ECU switches the output pin to VPWR and the actuator is connected to the output pin and ground.

The actual state of an output pin can be monitored using a corresponding internal digital monitor and two internal analogue monitor channels. The digital monitor channel simply reflects the on or off state of the actual output. The analogue monitor channels measure the actual voltage and current at the pin after scaling.

When the pin is used as a PWM, there are two possible uses for such a feedback:

Before starting a PWM, by reading the monitors on the pin to check for open or short circuits.

By reading the average voltage on a PWM outputs and comparing it with the demanded PWM width and the battery voltage reading you can perform a consistency check that the PWM output is performing as expected. This method can be applied if the PWM frequency is higher than the filter cut off frequency (100Hz).

Note

Pins A32, A33, A34, A35, and A45 have current monitors which are hardware filtered with a nominal cut off frequency of 884Hz. If the PWM frequency is greater than this cut off frequency, the average current through these pins can be measured.

Note

Pins A1, A17, A30, and A46 have current monitors which are not hardware filtered. Only the instantaneous current can be read.

When the pin is used as a plain digital output, feedback is used as follows:

Read the monitors on the pin to check for open or short circuits.

Note

The underlying timer for the M250 I/O has a rate of 4MHz.

Note

Because the platform does not sample the current feedback signal synchronised to the 'on' stage of the PWM output, the application cannot easily derive an average current reading.

The over-current trip state of an output pin can be monitored using a corresponding internal over-current monitor channel. In normal operation the internal over-current trip channel will be one. If the output channel experiences an over-current, the output channel will be forced off by the ECU and the over-current trip channel will be set to zero.

The over-current trip latch can be cleared and the tripped outputs enabled by the pss_OvercurTripReset Simulink block or by calling the pss_overcur_trip_reset() C-API function.

Note

To help component heat dissipation and to help prevent component stress, the platform software ensures there is at least 50ms between each request to clear the over current trip latches.

Note

The over-current trip channel has no function when a channel is configured as an injector. In this state, reading the channel will give undefined results.

The high-side output arrangement provides for a single switch (pin A16) to turn on or off actuators controlled by the ECU. Thus a load supplied by the high-side drive and controlled by a low-side drive has two independent means of being switched off, which is desirable for critical loads that must be turned off even if the low-side drive should fail in a conducting state.

Note

When using the high-side actuator output control, all loads controlled by a low-side drive output must be supplied by the high-side actuator output. If the system includes loads controlled by low-side drive outputs supplied by the high-side actuator output and others supplied directly from battery positive, there is a potential for a sneak path to provide power to some actuators even if the module is powered off. If it is desirable to connect loads controlled by low-side outputs directly to battery positive, then do not use the high-side actuator output to control power to other loads controlled by low-side outputs.

Warning

The digital outputs are not guaranteed to work properly when the ECU supply (battery) is outside 7V - 32V. It is recommended to monitor the ECU supply voltage on A2 and set the digital outputs to a safe state in your application software. The safe state depends on your application. In most applications, the safe state is to disable the outputs to protect the circuitry and to prevent unwanted output activation.

The high-side actuator output (pin A16) has a number of internal monitor signals (digital, voltage and current trip). However, there is a connection between the low-side output pins and the high-side actuator output monitor signals which can result in incorrect monitor signals when the high-side output is unconnected.

The diagram shows the connection between the low-side and high-side actuator outputs. The diode provides a current recirculation path for inductive loads. However, if both the low and high-side control is turned off, then the monitor signal should be ignored (especially if the low-side load has low resistance).

Recirculation diodes are present on output pins A18, A32, A33, A34, A35 and A45, however the diodes on A32, A33 and A34 are switched out of circuit when injector mode is selected and the output is switched off.

Warning

If there is a mixture of loads connected to the high-side actuator pin, and to VPWR direct, then when both the low and high-side control is turned off, the loads connected to the high-side actuator pin may draw current. For this reason, it is recommended that loads are only connected between the high-side actuator pin and those low-side output pins.

The injector outputs (pins A32, A33 and A34) allow the injector current to be regulated at two different levels, called the peak and the hold currents. The application software must provide two digital signals, one for the duration of the peak current and one for the duration of the peak and hold current. The application software must provide a clock for the injector current modulation (see internal channels A32, A33 and A34).

The internal injector clock channel must be configured to output a continuous 50% duty cycle square wave at an application determined frequency. This will typically be in the range 100Hz to 10KHz.

The peak and hold digital signals can be generated through the use of the pdx_PWMSynchronisedOutput Simulink block or the pdx_spwm_output() C-API function. The master channel corresponds to the peak signal, and the slave channel corresponds to the peak and hold signal. The master and slave channels must have identical frequency and the slave delay must be set to zero. The injector clock signal can be generated through the use of the pdx_PWMOutput or pdx_PWMVariableFrequencyOutput Simulink blocks or the pdx_pwm_output() C-API function.

Note

The over-current trip channel has no function when a channel is an injector or configured as an injector. In this state, reading the channel will give undefined results.

Note

When operating in injector mode, the hardware switches the recirculation diode into circuit when the peak and hold pulse is high and out of circuit when low. This results in a slow decay of the current during the off periods of the hardware generated PWM and a rapid decay of the current flow at the end of the injection period (to ensure the fastest possible closing of the injector).

The injector outputs (pins A32, A33 and A34) can be configured as either an injector output or a PWM output. The pin output mode can be selected through the use of the pcfg_Config_M250 Simulink block or the pcfg_setup_m250() C-API function.

When A32, A33 and A34 is configured as an injector channel, the corresponding internal current trip monitor channel will give undefined results.

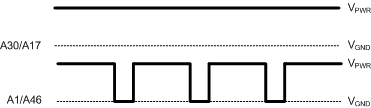

The H-bridge outputs (pins ) are controlled through the pdx_HBridge_Output Simulink block or the pdx_hbridge_output() C-API function.

The H-Bridge can be driven in four modes:

- No Drive

In no-drive mode, the H-bridge is turned off leaving the pins to float.

- Brake

In brake mode, both pins of the H-bridge are driven to VPWR.

- Forward

In forward mode, pin A30 (or A17) is driven to VPWR and pin A1 (or A46) pulsed, resulting in a current flow the opposite from the reverse mode.

- Reverse

In reverse mode, pin A1 (or A46) is driven to VPWR and pin A30 (or A17) is pulsed, resulting in a current flow the opposite from the forward mode.

Warning

To avoid unexpected behavior, H-bridges should be set to NO DRIVE mode before flashing the ECU. This can be done by commanding the actuators to NO DRIVE any time the engine is not turning.

The frequency and the duty cycle of operation are controlled by the application. There are monitor inputs to check the output pin state.

Note

The H-Bridge pins can also be used separately as high-side or low-side drivers. It is not possible to use an H-bridge in both configurations in the same application.

Warning

The digital outputs are not guaranteed to work properly when the ECU supply (battery) is outside 7V - 32V. It is recommended to monitor the ECU supply voltage on A2 and set the digital outputs to a safe state in your application software. The safe state depends on your application. In most applications, the safe state is to disable the outputs to protect the circuitry and to prevent unwanted output activation.

Some of the internal and external inputs and outputs are classed as serial. The connector pinout tables and internal channel tables above specify whether a pin or channel is serial or not.

When a serial input is read, the measurement reflects the value of the input taken last time the application task ended. I.e., the value of the input is delayed by one cycle of the task period. When a serial output is set, the driven state is updated at the end of the current application task. I.e., there is a delay between requesting a change in the output state, and the output state honoring that request.

The CAN buses (pins A28+A43 and A29+A44) are implemented using high-speed CAN transceivers. CAN bus 1 has terminating resistors fitted, CAN bus 0 doesn't.

The ECU supports different memory configurations for application, calibration and RAM sizes, some of which require external calibration RAM (see Section 4.22, “Memory — calibration capabilities”).

Table 4.5. Memory configurations supported

|

Configuration |

App size (KiB) |

Cal size (KiB) |

RAM size (KiB) |

External RAM required? |

Run-time

calibration supported? |

|---|---|---|---|---|---|

| A [a] | 512 | 256 | 64 | N | N |

| 512 | 256 | 64 | Y | Y | |

| B | 512 | 256 | 832 | Y | Y |

| C | 640 | 128 | 192 | Y | Y |

| D | 768 | 64 | 768 | Y | Y |

[a] If an OpenECU target that supports memory configuration is loaded with an application in which no such configuration has been specified, then configuration A will be used as the default. | |||||

The ECU supports non-volatile memory storage in Flash. Battery backed RAM is not supported.

The processor's Flash memory is split into small and large memory blocks. The application and calibration are stored in large blocks, whilst DTC information, freeze frames and so on are stored in small blocks.

The largest Flash block can take up to approximately 7.5 seconds to erase. This occurs in an environment where the Flash has been erased and programmed many times at its temperature extreme. The typical erase time is smaller, especially at ambient temperatures. Reprogramming an ECU (where many large blocks would be erased), or storing DTC information across power cycles, can therefore take some time. Users and applications should take this into consideration.

The minimum number of erase cycles is approximately 1,000 for large Flash blocks and 100,000 for small Flash blocks. This occurs in an environment where the Flash has been erased and programmed many times at its temperature extreme. The typical number of erase cycles is larger, especially at ambient temperatures.

The minimum data retention is approximately 5 years for blocks which have been erased less than 100,000 times, and approximately 20 years for blocks which have been erased less than 1,000 times.

The information about the Flash has been taken from Freescale's MPC5534 Microcontroller Data Sheet document, revision 4 (dated Mar 2008).

The ECU supports both offline calibration (where all of the ECU's calibration memory is reprogrammed whilst the application is stopped) and online calibration (where individual calibrations can be modified whilst the application runs). These calibration capabilities are supported through two ECU types:

Developer ECUs — Supports offline and online calibration Uses an external RAM device to map calibrations, normally stored in non-volatile memory, to RAM to support modifications of calibration whilst the application runs. This provides all of the processor's RAM for the application and platform library, whilst adding additional RAM to support calibration.

Fleet ECUs — Does not provide external RAM or the ability to calibrate whilst the application runs (offline calibration is still supported). These units are lower-cost and intended for fleet trials or production.

The ECU can run in one of two system modes: reprogramming mode and application mode. In reprogramming mode, the ECU can be reprogrammed with application software from a calibration tool. In application mode, the ECU runs the programmed application software. The ECU selects which mode to enter when it is powered up by measuring the external FEPS A27 pin.

Table 4.6. System mode selection

| FEPS (A27) Voltage | System mode |

|---|---|

| >= +13V | Enter reprogramming mode. If valid application software has previously been programmed, then use the CCP settings from that application, otherwise use the default CCP settings. |

| <= -18V | Enter reprogramming mode. Use the default CCP settings. [a] |

| Otherwise | Enter application mode if valid application software has previously been programmed, otherwise enter reprogramming mode. |

[a] In early revisions of the hardware, using this negative voltage may damage the ECU, please consult the errata associated to your revision before using this functionality. | |

The ECU also uses the FEPS input (pin A27) as an output to flash an optional LED. The LED is connected between VPWR (pin A2) and FEPS (pin A27). Note that the pin use as FEPS input or as lamp output is mutually exclusive.

Note

Pin A27 can supply up to 10mA, it is not capable of lighting a bulb.

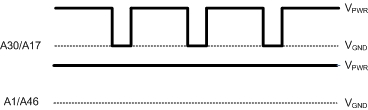

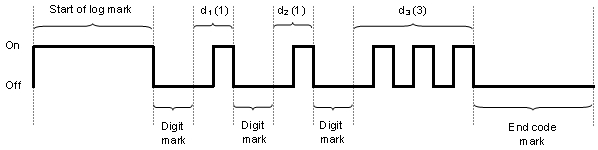

The flash sequence represents a set of codes. Each code is a three digit number, where each digit is flashed a number of times equal to its value.

An example would be the flash sequence for code 113. The flash sequence is broken down into a series on marks, or on and off pulses as follows:

Each of the marks lasts for a specific duration:

Table 4.7. Flash code example

| Mark | Duration and meaning |

|---|---|

| Start of log mark | 3s — marks the start of the flash code list |

| Digit mark | 1s — marks the start of a digit |

| dn | ns — n digits, where the output is turned OFF for 0.5 second, then ON for 0.5 seconds, n times |

| End code mark | 3s — marks the end of a code (i.e., end of 3 digits) |

After the end code mark, the ECU will either flash the next code, or return to the start of the list and flash the first code. The ECU always has at least one code to flash.

Each code represents information about the ECU state. If there is no flash sequence, or a malformed flash sequence, then the ECU is malfunctioning. Otherwise, the flash sequence will represent one of the following codes:

Table 4.8. Flash codes

| Code | Meaning |

|---|---|

| 111 | In application mode — no other condition has been detected. |

| 112 | In reprogramming mode with the FEPS pin negative. |

| 113 | In reprogramming mode with the FEPS pin high. |

| 114 | In reprogramming mode via a FEPS-less reprogramming request. |

| 115 | In reprogramming mode because no valid application software exists. |

| 116 | In reprogramming mode due to FEPS pin electrical failure. |

| 117 | In reprogramming mode due to repeated reset during application mode. |

| 118 | In reprogramming mode due to failed application checksum tests. |

| 128 | In reprogramming mode due to failed memory check tests. |

| 119 | In reprogramming mode due to a FEPS-less ISO reprogramming request. |

| 121 | In reprogramming mode due to an unknown failure. |

| 123 | In reprogramming mode due to a watchdog reset. |

| 222 | In reprogramming mode due to the application not having a valid license. |

Developer units have the capability to accept calibration changes while the application software is running.

The ECU closely adheres to the IEEE-754 for floating point numbers.

When using Simulink, floating point Simulink models are supported — all calculations are performed using single-precision (even if the model uses double-precision, the ECU performs calculations using single-precision).

When using the C-API, floating point applications are supported — all calculations are performed using single or double precision, as determined by the application code (although double precision will incur some software overhead — see the compiler reference manual for further details).

The rounding mode is set to round-to-nearest. In some conditions, the ECU will not adhere to the IEEE-754 standard:

Table 4.9. Floating point conditions

| Condition | Result |

|---|---|

| Underflow | The result of a calculation underflow is ±0. The sign is based on the signs of the operands. |

| Overflow | The result of a calculation overflow is ±max where max is approximately 3.4 × 1038. The sign is based on the signs of the operands. |

| Divide by zero |

The ECU does not generate ±Inf, NaN or a denormalised number as the result of a calculation.

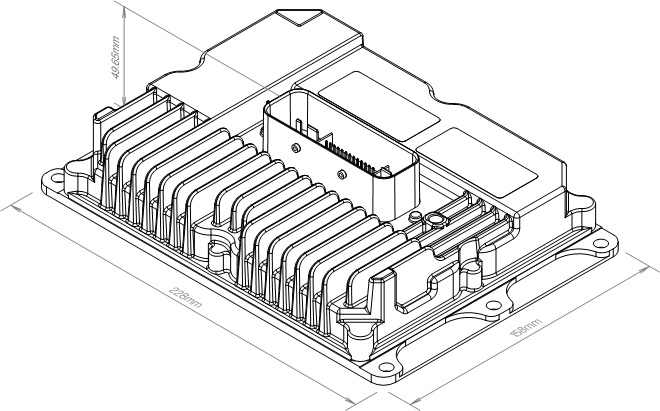

The ECU has the following dimensions:

If you have questions, or are experiencing issues with OpenECU please see the FAQ website:

- website

If you still have questions after searching through the FAQ, or want to discuss sales or proposals, you can contact main office:

- Tel

- +1 734 656 0140

- Fax

- +1 734 656 0141

during normal working hours (Mon to Fri, 0930 to 1700 EST).