Determine whether a crankshaft wheel is moving or not.

None (Main library). (See Section 2.3, “Licensed Features”.)

The pan_CrankWheelMovement block retrieves whether the crankshaft wheel is moving or not. The ECU continually monitors the crankshaft wheel input signal looking for tooth edges. If the crankshaft signal decoding state machine has reached state Detect AB or higher, then the ECU declares the wheel as moving. See Section 6.1.2.4, “Crank decoding” for a description of the crank decoding state machine.

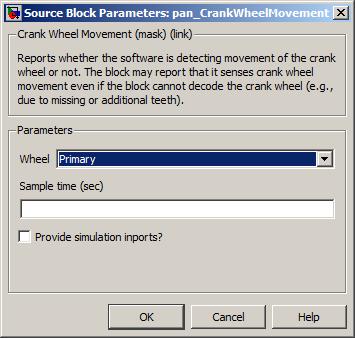

Only used under simulation. Under simulation, the value of this inport is passed through to outport movement.

Value type: Boolean

A drop down to identify the crankshaft wheel to measure for movement. The selection of wheel must match a pan_CrankWheelConfig block elsewhere in the model.

Value type: List Calibratable: No The periodicity of the block execution.

Range: [0.001, 3600] seconds

Value type: Real Calibratable: No Tick to enable inport sim_movement.

Value type: Boolean Calibratable: No