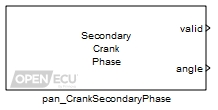

Retrieve the phase angle of a secondary crankshaft wheel relative to the primary wheel.

None (Main library). (See Section 2.3, “Licensed Features”.)

The pan_CrankSecondaryPhase block provides the current phase angle of the specified secondary crankshaft wheel relative to the primary crankshaft wheel that generates the angle clock. The crankshaft encoder wheel pattern need not be the same for the primary and secondary inputs.

The ECU continuously monitors the primary and secondary crankshaft wheel signals. The ECU measures the phase on each tooth of a secondary crankshaft wheel, as the difference between the angle clock of the primary crankshaft wheel and the angle of the secondary crankshaft wheel tooth.

The phase angle is always a value between 0° and 360° and represents the secondary wheel angle minus the primary wheel angle, so that if the secondary wheel is 10° in advance of the primary, it will return a value of 10, and if the primary wheel is 10° in advance of the secondary it will return a value of 350.

Set to zero when the ECU cannot provide a phase angle (for instance, if the ECU has not synchronised with both the primary and the selected secondary crankshaft wheels), set to one when the outport angle is valid.

Value type: Boolean The estimated phase angle of the specified secondary crankshaft wheel encoder relative to the primary crankshaft wheel encoder.

Range: [0, 360) ° crank Resolution: at least 0.1 degrees

Value type: Real

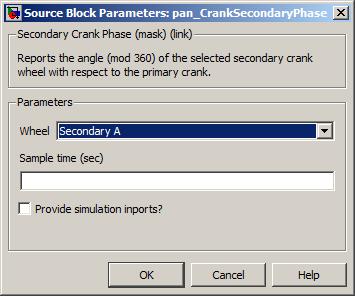

A drop down to identify the crankshaft wheel for angle measurement. The selection of wheel must match a pan_CrankWheelConfig block elsewhere in the model. There must also be a pan_CrankWheelConfig block for the Primary crank wheel present in the model.

Value type: List Calibratable: No The periodicity of the block execution.

Range: [0.001, 3600] seconds

Value type: Real Calibratable: No Tick to enable inports sim_valid and sim_angle.

Value type: Boolean Calibratable: No