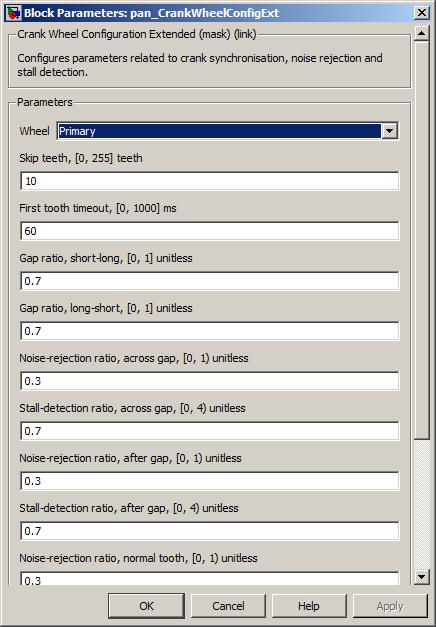

Configure the extended parameters for decoding a crankshaft wheel encoder, including missing tooth detection, noise rejection and stall detection.

None (Main library). (See Section 2.3, “Licensed Features”.)

The pan_CrankWheelConfigExt block configures sync point detection, noise rejection and stall detection parameters for decoding one or more crankshaft sensor inputs. A detailed explanation of the parameters is given in Section 6.1.2.4, “Crank decoding”.

If this block is not present in an application model then the parameters default, as detailed in each of the mask parameters. A pan_CrankWheelConfig block must be present in the model for the other crankshaft related blocks to operate.

A drop down to identify the crankshaft wheel to configure. The selection of wheel is dependent on the target ECU hardware selected in the put_Identification block.

Value type: List Calibratable: No Number of processed teeth edges to ignore during ECU initialisation, used to ignore electrical noise during power up. Set to zero to calibrate out this decoding step.

Range: [0, 255] teeth

Value type: Integer Calibratable: Yes, offline The minimum time between processed teeth edges before the crank decode logic will continue. Effectively sets the minimum speed before searching for crank synchronisation. Set to zero to calibrate out this decoding step.

Range: [0, 1000] milliseconds

Value type: Real Calibratable: Yes, offline The ratio of the inter-tooth time immediately before the missing tooth region to the time across the missing tooth region, below which the crank decode logic determines a missing tooth region has been detected.

Range: [0, 1)

Value type: Real Calibratable: Yes, offline The ratio of the inter-tooth time immediately after the missing tooth region to the time across the missing tooth region, below which the crank decode logic determines a missing tooth region has been detected.

Range: [0, 1)

Value type: Real Calibratable: Yes, offline Noise-rejection ratio, across gap

The ratio of the inter-tooth time that the crank decode logic will ignore processed crank teeth edges, for the tooth immediately proceeding the missing tooth region. Set to zero to remove noise-rejection functionality.

Range: [0, 1)

Value type: Real Calibratable: Yes, offline Stall-detection ratio, across gap

The ratio of the inter-tooth time proceeding the missing tooth region, added to the next expected tooth edge, to calculate the crank stall timeout. If a processed tooth edge has not been seen by the timeout, the crank decode logic will assume the wheel has stalled.

Range: [0, 4)

Value type: Real Calibratable: Yes, offline Noise-rejection ratio, after gap

The ratio of the inter-tooth time that the crank decode logic will ignore processed crank teeth edges, for the tooth immediately after the missing tooth region. Set to zero to remove noise-rejection functionality.

Range: [0, 1)

Value type: Real Calibratable: Yes, offline Stall-detection ratio, after gap

The ratio of the inter-tooth time after missing tooth region, added to the next expected tooth edge, to calculate the crank stall timeout. If a processed tooth edge has not been seen by the timeout, the crank decode logic will assume the wheel has stalled. The inter-tooth time is calculated using the missing tooth region time, divided as if there were no missing teeth.

Range: [0, 4)

Value type: Real Calibratable: Yes, offline Noise-rejection ratio, normal tooth

The ratio of the inter-tooth time that the crank decode logic will ignore processed crank teeth edges, for teeth not immediately before or after the missing tooth region. Set to zero to remove noise-rejection functionality.

Range: [0, 1)

Value type: Real Calibratable: Yes, offline Stall-detection ratio, normal tooth

The ratio of the inter-tooth time added to the next expected tooth edge, to calculate the crank stall timeout. If a processed tooth edge has not been seen by the timeout, the crank decode logic will wait for a further tooth time (see Stall-detection ratio, timeout tooth) before declaring crank stall.

Range: [0, 4)

Value type: Real Calibratable: Yes, offline Noise-rejection ratio, timeout tooth

If the crank decode logic declares crank stall for a normal tooth, the crank decode logic will try waiting an additional period of time before declaring stall. The ratio is used as before. Set to zero to remove noise-rejection functionality.

Range: [0, 1)

Value type: Real Calibratable: Yes, offline Stall-detection ratio, timeout tooth

If the crank decode logic declares crank stall for a normal tooth, the crank decode logic will try waiting an additional period of time before declaring stall. The ratio is used as before. If this second timeout triggers then the crank decode logic declares the crank stalled.

Range: [0, 4)

Value type: Real Calibratable: Yes, offline