Configure the parameters used to sample a knock sensor.

None (Main library). (See Section 2.3, “Licensed Features”.)

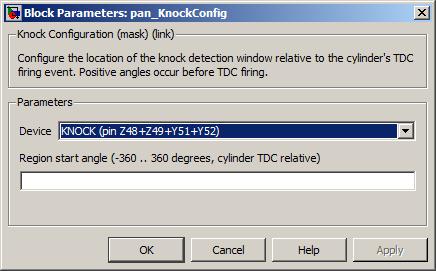

The pan_KnockConfig block configures the knock processing functionality and sets the earliest starting angle of any knock detection window relative to each cylinder's TDC-firing angle.

Note

The angle sense differs from most other angular blocks. A positive value denotes an angle before TDC-firing, and a negative value denotes an angle after TDC-firing. See Section 6.2.1, “Relative angles to TDC-firing” for more).

See the Section 6.4, “Knock sensor processing” for an overview of knock sensor processing. In short, the application schedules a sample window in which to process a knock sensor signal using the pan_KnockDetectionWindow block. The parameters that can be adjusted for knock processing are set by the application using the pan_KnockFilter_Hip901x block. Shortly after the end of each sample window, the ECU completes knock signal processing and buffers the result which can be retrieved by the application using the pan_KnockFeedback block.

The HIP901x device, as identified by the input pins it is associated with.

Value type: List Calibratable: No The earliest starting angle of any knock detection window relative to a cylinder's TDC-firing angle (positive angles before TDC-firing).

Range: [360, -360] ° crank Resolution: at least 0.1 degrees

Value type: Real Calibratable: Yes, offline